炭化タングステン切削工具の研磨と再生方法

タングステンカーバイド切削工具は、驚異的な耐久性と長寿命の刃先保持力で知られています。しかし、どんなに強力な工具でも、日常的な使用によって摩耗します。鈍くなった工具を毎回交換するのではなく、研磨または再調整することで、性能を回復させ、寿命を延ばすことができます。これはコスト削減だけでなく、安定した加工品質の維持と生産停止時間の削減にもつながります。この記事では、タングステンカーバイド切削工具の研磨と再調整について知っておくべきことをすべて解説します。研磨のタイミング、必要な工具、再調整と単純な研磨の違いなど、このガイドは、初心者から熟練の機械工まで、技術の向上を目指す方に最適です。[…]

炭化タングステン切削工具の寿命を延ばすためのメンテナンスのヒント

タングステンカーバイド切削工具は、その強度、耐久性、耐摩耗性で知られています。しかし、どんなに頑丈な工具でも、適切なメンテナンスをしなければ永遠に使えるわけではありません。カーバイド工具を最大限に活用し、時間と費用の無駄を省くには、適切なメンテナンス習慣が不可欠です。このガイドでは、タングステンカーバイド切削工具の寿命を延ばすためのシンプルで実用的なヒントを解説します。CNCショップを経営している場合でも、小規模なワークショップを運営している場合でも、これらの戦略は工具の摩耗を軽減し、性能を向上させ、生産を円滑に進めるのに役立ちます。1. 工具を清潔に保つ 汚れた工具は摩耗が早くなります。工具の刃先に切削片、埃、材料が付着すると[…]

炭化タングステン切削工具が優れた耐摩耗性を持つ理由

現代の機械加工において、工具の摩耗は最大の課題の一つです。工具の摩耗が早すぎると、仕上がりが悪くなったり、生産速度が低下したり、コストが上昇したりします。だからこそ耐摩耗性が重要であり、タングステンカーバイド切削工具が真価を発揮するのはまさにこの点です。タングステンカーバイドは単なる工具材料ではありません。入手可能な材料の中で最も硬く、耐摩耗性に優れた材料の一つであり、過酷な加工作業に最適です。しかし、なぜタングステンカーバイドはこれほど耐久性が高いのでしょうか?そして、高速度鋼などの従来の工具材料よりも優れた性能を発揮するのでしょうか?この記事では、その理由を分かりやすく解説します。CNC工作機械を扱っている方にも、難削材を扱っている方にも、タングステンカーバイドがなぜ優れているのかをご説明します。[…]

切削工具用途における炭化タングステングレードの理解

切削工具といえば、強度、スピード、信頼性を求めるプロフェッショナルにとって、タングステンカーバイドは頼りになる素材です。しかし、すべてのカーバイド工具が同じ品質というわけではありません。選択するタングステンカーバイドのグレードは、工具の性能と寿命に大きく影響します。アルミニウム、鋼、複合材など、どのような材料を切削する場合でも、適切なカーバイドグレードを使用することが最良の結果を得る鍵となります。このガイドでは、カーバイドグレードの意味、重要性、そして作業に最適なグレードの選び方について解説します。1. タングステンカーバイドグレードとは?タングステンカーバイドグレードとは、タングステンカーバイドと他の材料(コバルトなど)の様々な混合物を指します。[…]

炭化タングステン切削工具が加工効率と精度を向上させる仕組み

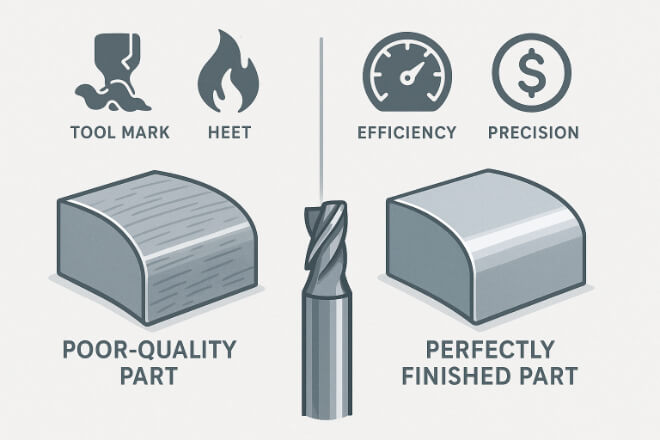

現代の機械加工では、スピードと精度が何よりも重要です。CNC工作機械で部品を製造している場合でも、大規模な製造業を管理している場合でも、切削工具の品質は生産量、コスト、そして製品品質に直接影響します。そのため、多くの業界で従来の工具から炭化タングステン切削工具への切り替えが進んでいます。しかし、炭化タングステン切削工具の何が特別なのでしょうか?そして、炭化タングステン切削工具はどのようにして機械加工の性能を向上させるのでしょうか?1. 炭化タングステンとは?炭化タングステンとは、タングステンと炭素原子からなる化合物です。非常に硬く、鋼鉄の約2倍の硬さで、高温でも軟化することなく耐えることができます。実際、製造業で使用される材料の中で、ダイヤモンドと[…]に次ぐ最も硬い材料の一つです。

タングステンカーバイド切削工具の主な用途(業界別)

タングステンカーバイド切削工具は、非常に硬く、耐久性が高く、鋭い切れ味を維持するのに優れていることで知られています。これらの工具は、航空宇宙産業から木工産業まで、多くの業界で使用されています。これは、通常の鋼製工具では不可能な過酷な作業にも対応できるためです。この記事では、タングステンカーバイド切削工具が最も多く使用されている業界、これらの工具が好まれる理由、そしてどのように性能を向上させるかについて解説します。CNC工作機械を経営する方でも、重機修理に携わる方でも、これらの工具を理解することで、より適切な工具を選び、よりスマートに作業を進めることができます。1. タングステンカーバイド切削工具が業界で使用されている理由 タングステンカーバイドは単に硬いだけではありません。鋼の約2倍の強度を持ち、高温や急速な摩耗にも耐えることができます。[…]

炭化タングステン vs. 高速度鋼: どちらの切削工具が優れていますか?

切削工具といえば、タングステンカーバイドと高速度鋼(HSS)という2つの素材が頻繁に挙げられます。どちらが作業に適しているかお悩みなら、速度、耐久性、予算のどれを重視するかによって答えは異なります。しかし、長持ちする工具、優れた性能、そしてより高速な加工を求めるなら、タングステンカーバイドが断然優れています。このガイドでは、分かりやすく解説します。タングステンカーバイドとHSSの違い、それぞれの用途、そして現代のほとんどの用途において超硬切削工具が優れている理由を学びます。1. 高速度鋼(HSS)とは? 高速度鋼は、切削工具に使用される硬化鋼の一種です。[…]

用途に適した炭化タングステン切削工具の選び方

タングステンカーバイド切削工具は強度、速度、信頼性に優れていますが、適切な工具を選ぶのは必ずしも簡単ではありません。種類、コーティング、用途が非常に多いため、特に工具の専門家でない場合は、戸惑ってしまうのも当然です。この初心者向けガイドでは、作業に最適なタングステンカーバイド切削工具の選び方を具体的にご紹介します。穴あけ、フライス加工、旋削など、どのような加工でも、より良い結果を得るために、よりスマートな工具選びの方法を学ぶことができます。1. 適切な工具選びが重要な理由 切削工具は小さく見えるかもしれませんが、その影響は大きいです。不適切な工具を使用すると、仕上がりが粗くなったり、工具が破損したり、過熱したり、CNC工作機械が損傷したりする可能性があります。[…]

CNC加工における炭化タングステン切削工具の使用の利点

CNC加工では、精度と生産性が重要です。高精度部品を1つ製造する場合でも、フルラインで稼働させる場合でも、切削工具は大きな役割を果たします。その中でも際立った材料が1つあります。それはタングステンカーバイドです。ますます多くの機械工場やメーカーがタングステンカーバイド切削工具に切り替えていますが、それには十分な理由があります。これらの工具は強度が高いだけでなく、時間の節約、コスト削減、品質向上にも役立ちます。この記事では、CNC加工でタングステンカーバイド切削工具を使用する真のメリットを、わかりやすく解説します。1. 工具寿命の延長 = 交換回数の削減 タングステンカーバイド工具の最大のメリットの一つは、その非常に長い寿命です。[…]

炭化タングステン切削工具とは?初心者向け完全ガイド

今日の急速に変化する製造業では、切削工具は強度、精度、そして耐久性が求められます。そこでタングステンカーバイド切削工具の出番です。これらの工具は、自動車、航空宇宙、建設、石油・ガスなど、ほぼすべての業界で使用されています。これは、最も硬い材料も容易に切断できるためです。機械加工の初心者の方、あるいは単に産業用工具に興味がある方のために、この初心者向けガイドでは、タングステンカーバイド切削工具について知っておくべきことをすべて理解するのに役立ちます。タングステンカーバイド切削工具とは何か、どのように作られるのか、何が特別なのか、そして実際の使用方法について解説します。1. タングステンカーバイドとは?タングステンカーバイドは、2つの元素を組み合わせて作られる超硬質材料です。[…]