高速加工における炭化タングステン切削工具の役割

競争の激しい今日の製造業界では、スピードこそが全てです。企業は、ダウンタイムと廃棄物を削減しながら、高品質な部品をより速く生産する必要があります。そこで登場するのが高速加工(HSM)です。これは、切削速度と送り速度を高速化することで生産性を向上させるプロセスです。しかし、落とし穴があります。すべての工具がこのような過酷な条件に耐えられるわけではないのです。そこで、タングステンカーバイド切削工具が大きな力を発揮します。タングステンカーバイドは、靭性、硬度、耐熱性を兼ね備えており、高速加工に最適です。この記事では、これらの工具がどのように加工速度の向上、部品品質の向上、運用コストの削減に貢献するのかを探ります。航空宇宙、自動車、金型製造、一般的なCNC加工などの業界に携わっている方は、ぜひ読み進めてください。[…]

コーティングなしとコーティングありの炭化タングステン切削工具の違い

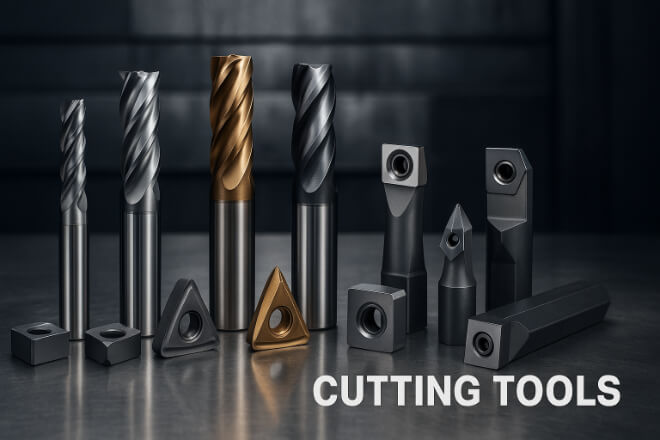

タングステンカーバイド切削工具は、航空宇宙、自動車、金型製造、精密機械加工などの業界で信頼されています。その強度、耐摩耗性、そして切削速度は、不可欠な要素となっています。しかし、加工業界の意思決定者の多くは、コーティングなしとコーティング付きのどちらを選ぶべきか迷っています。このガイドでは、コーティングなしとコーティング付きのタングステンカーバイド切削工具の実際の違いを分かりやすく解説します。コーティングが工具寿命、性能、コストにどのような影響を与えるかを示し、お客様の業務に最適な選択を支援します。コーティングなしのタングステンカーバイド工具とは?コーティングなしのタングステンカーバイド工具は、表面処理を施さないタングステンカーバイド単体で作られています。高い硬度を誇り、広く使用されています。[…]

炭化タングステン切削工具の適切な保管方法

タングステンカーバイド切削工具は、その強度、硬度、そして長寿命で知られています。これらの工具は過酷な作業にも耐え、高温・高圧下でも動作し続けます。しかし、どんなに強力な工具であっても、特に使用していない時は適切な手入れが必要です。不適切な保管は、錆、損傷、欠け、あるいは時間の経過とともに性能低下につながる可能性があります。このガイドでは、タングステンカーバイド切削工具を安全かつ効果的に保管するための最適な方法をご紹介します。CNCショップ、工具室、あるいは大規模な製造施設の管理者であっても、これらの簡単な保管のヒントは、コスト削減、ダウンタイムの削減、そして工具の寿命延長に役立ちます。適切な保管が重要な理由 タングステンカーバイド工具の保管 […]

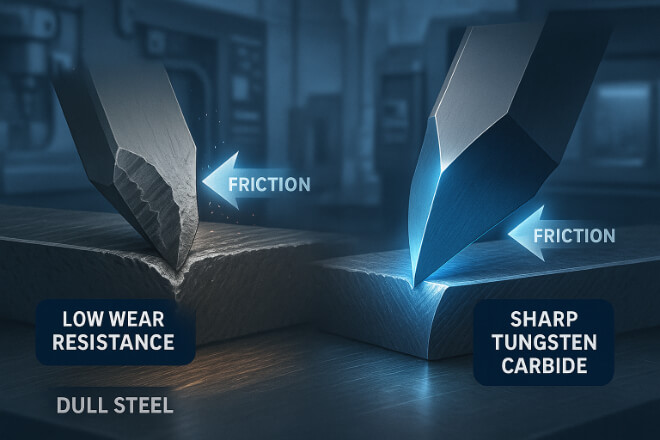

炭化タングステン切削工具の耐摩耗性に関する科学

硬質材料の加工や長期にわたる生産サイクルにおいては、タングステンカーバイド切削工具が第一選択肢となることがよくあります。これらの工具は優れた耐摩耗性で知られていますが、その強さは一体何によってもたらされるのでしょうか?この記事では、タングステンカーバイド工具が過酷な条件下でも長寿命で、損傷に強く、きれいな切削状態を維持できる理由を科学的に解説します。CNC工場を経営する場合でも、工具調達を管理する場合でも、耐摩耗性を理解することで、より優れた工具を選択し、ダウンタイムを削減し、総加工コストを削減することができます。耐摩耗性とは?なぜ重要なのか?耐摩耗性とは、材料が摩耗や摩耗によって徐々に生じる表面損傷に耐える能力のことです。[…]

炭化タングステン切削工具の設計と材料における革新

今日の競争の激しい製造環境において、私たちは常に、より速く、より長く、より高品質な部品を製造する方法を模索しています。タングステンカーバイド切削工具は、高性能加工における頼りになるソリューションとして既に確固たる地位を築いています。しかし、イノベーションは止まるところを知りません。近年、タングステンカーバイド工具の設計と材料は目覚ましい進歩を遂げ、生産性をさらに向上させています。この記事では、超硬切削工具の最新トレンド、すなわち新しい材料、コーティング、微細構造、そして設計戦略が、どのように性能を変えているのかを探ります。加工や工具選定のプロセスにおいて意思決定を行う立場にある方にとって、これらの最新情報は、より賢明な投資を行い、競合他社に先んじるのに役立つでしょう。1. なぜ[…]

炭化タングステン切削工具の製造工程の説明

タングステンカーバイド切削工具は、その強度、耐久性、そして最も硬い材料でさえも切削できる能力で知られています。しかし、これらの工具はどのように作られるのでしょうか?多くの人が日々の加工作業でカーバイド工具を使用していますが、その複雑で魅力的な製造工程を理解している人はほとんどいません。この記事では、粉末から完成品に至るまで、タングステンカーバイド切削工具の製造工程全体を、分かりやすい言葉と明確な手順で解説します。工場長、調達責任者、エンジニアなど、どのような立場の方でも、これらの工具の製造方法を理解することで、適切なサプライヤーを選び、一貫した品質を確保することができます。1. 原材料:タングステンとコバルト この工程は原材料から始まります。主に[…]

炭化タングステン切削工具の硬度と靭性のバランスを理解する

タングステンカーバイド切削工具は、硬く、耐久性に優れ、過酷な条件下でも優れた性能を発揮するため、機械加工業界で広く使用されています。しかし、見落とされがちな重要な要素が、硬度と靭性のバランスです。このバランスを適切に取ることで、簡単に破損してしまう工具と、長く効率的に使用できる工具の違いが生まれます。このブログでは、切削工具における硬度と靭性の意味、それらがなぜ重要なのか、そして加工ニーズに応じて適切なバランスを選択する方法について説明します。1. タングステンカーバイド工具の硬度とは?硬度とは、材料が摩耗や変形に耐える能力のことです。[…]

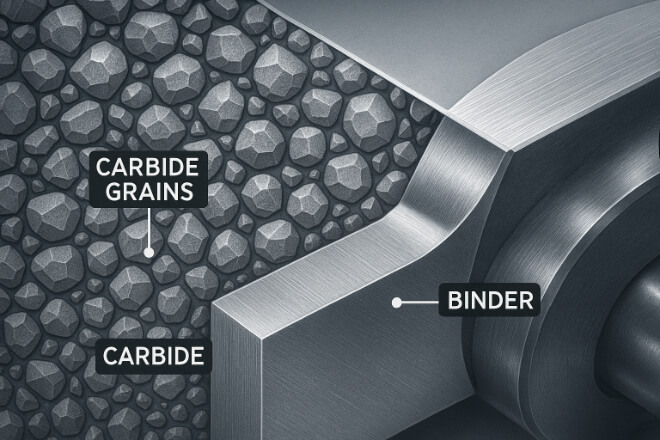

炭化タングステンの微細構造が切削工具の性能に与える影響

タングステンカーバイド切削工具は、現代の製造業に不可欠です。硬く、強靭で、高速加工において高い信頼性があることで知られています。しかし、これらの工具の優れた性能の理由を理解しようとする意思決定者は多くありません。重要な要素の一つが微細構造、つまりタングステンカーバイド材の微細な内部構造です。この記事では、タングステンカーバイドの微細構造とは何か、それが工具の性能にどのように影響するか、そして加工ニーズに適した工具を選ぶ際に何に注意すべきかを説明します。タングステンカーバイドの微細構造とは?タングステンカーバイドは、2つの部分からなる複合材料です。タングステンカーバイド粒子(切削を行う硬質粒子)とコバルトバインダー(粒子を保持する金属)です。[…]

炭化タングステン切削工具に関するよくある質問

機械加工と製造の世界では、タングステンカーバイド切削工具はその強度、耐久性、そして性能から高い信頼を得ています。しかしながら、多くの専門家、特に意思決定者は、これらの工具の仕組み、使用時期、そして最良の結果を得る方法について疑問を抱いています。このガイドでは、よくある質問に、シンプルで明確な言葉でお答えします。タングステンカーバイド切削工具とは?タングステンカーバイド切削工具は、タングステンと炭素を組み合わせた硬くて密度の高い材料で作られています。鋼よりもはるかに硬く、切れ味が長持ちします。これらの工具は、高温や硬い材料にも耐えられるため、CNC加工、金属切削、穴あけ加工に使用されます。[…]

炭化タングステン切削工具の損傷検査方法

タングステンカーバイド切削工具は、強度と耐久性に優れ、硬い材料を容易に切削できるため、機械加工に広く使用されています。しかし、どんなに頑丈な工具でも、いずれは摩耗したり損傷したりします。損傷を早期に発見しないと、表面仕上げの劣化、部品の精度低下、機械の故障、さらには工具の破損につながる可能性があります。機械加工や製造の意思決定者にとって、安定した品質を確保し、コストのかかるダウンタイムを回避するために、超硬工具の定期的な検査は不可欠です。このガイドでは、タングステンカーバイド切削工具の損傷検査方法、確認すべき兆候、使用できる工具、そして情報に基づいた意思決定を行う方法について解説します。[…]