炭化タングステン切削工具の価格:知っておくべきこと

金属切削において、タングステンカーバイド切削工具は市場で最も優れた選択肢の一つです。強度と耐久性に優れ、高速加工にも容易に対応できます。しかし、多くのメーカーにとって、ある疑問が常に浮かび上がります。それは、「タングステンカーバイド切削工具の価格はいくらなのか?」ということです。これらの工具の価格は、様々な要因によって大きく変動します。この記事では、タングステンカーバイド切削工具の価格に影響を与える要因、選択肢の比較方法、そして最適な価格帯の工具を選ぶためのヒントを解説します。生産管理者、購買担当者、あるいは経営者など、価格体系を理解することで、より賢明な購入決定を下すことができます。[…]

旋盤用超硬切削工具

超硬切削工具は、現代の旋盤加工に欠かせないものとなっています。これらの工具は、高硬度、長寿命、そしてステンレス鋼、焼入れ鋼、鋳鉄などの難削材の切削能力で知られています。加工効率の向上とダウンタイムの削減を目指す企業にとって、超硬旋盤工具を選択することは賢明かつ戦略的な選択です。このガイドでは、旋盤における超硬工具の仕組み、種類、利点、性能向上のヒント、そして生産性向上のための適切な超硬工具の選び方について解説します。超硬切削工具とは?超硬切削工具は、高温・高圧にも耐えられる非常に硬い素材であるタングステンカーバイドで作られています。[…]

炭化タングステンはどのように切削工具の性能を向上させるのでしょうか?

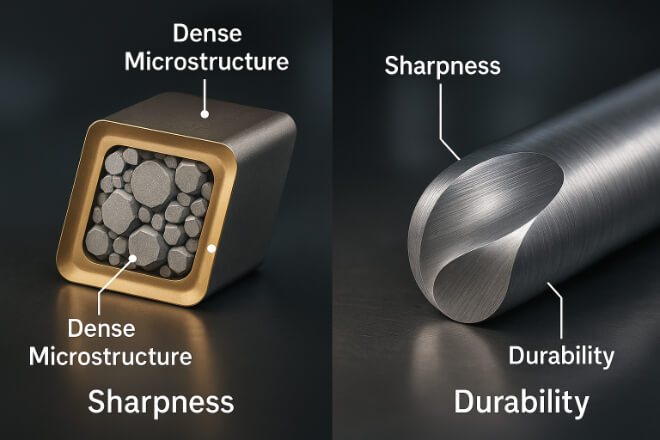

精密機械加工の世界では、切削工具の性能が全てです。航空宇宙、自動車、医療機器などの金属部品を成形する場合でも、常に鋭く、きれいに切れ、長持ちする工具が必要です。そこでタングステンカーバイドが活躍します。タングステンカーバイド切削工具は、極めて高い硬度、優れた耐摩耗性、そして圧力下でも高い信頼性で知られています。しかし、タングステンカーバイドの何が特別なのでしょうか?そして、実際にどのように切削工具の性能を向上させるのでしょうか?タングステンカーバイドとは?タングステンカーバイドは、タングステン(W)と炭素(C)という2つの元素から構成される化合物です。高圧・高温下で混合すると、ダイヤモンドに匹敵する硬さを持つ材料になります。ほとんどのタングステン[…]

炭化タングステン切削工具の利点

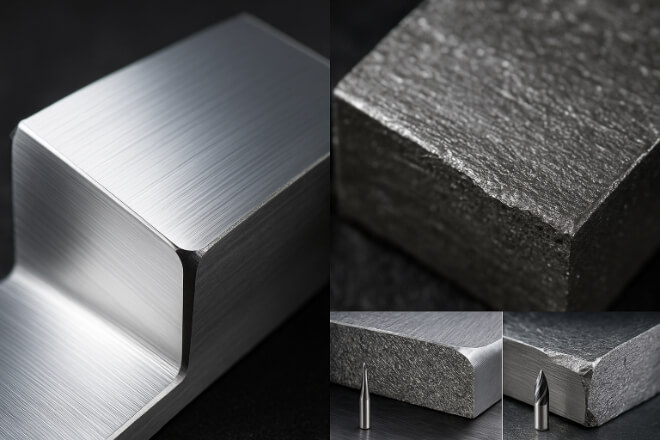

金属切削の世界では、精度が重要です。工具寿命、表面仕上げ、そして全体的な生産コストも同様に重要です。そこでタングステンカーバイド切削工具が真価を発揮します。これらの工具は、航空宇宙、自動車、医療、石油・ガスなど、多くの業界のプロフェッショナルに使用されています。しかし、なぜこれほど人気があるのでしょうか?なぜ多くのメーカーが高速度鋼(HSS)などの素材からタングステンカーバイド工具に切り替えているのでしょうか?このブログでは、これらの工具が際立つ主な理由、加工性能を向上させる方法、そして切り替えによって期待できるメリットについて説明します。優れた切削性能を実現する超高硬度タングステンカーバイドは、世界で最も硬い工具材料の一つです[…]

炭化タングステン工具の切削速度の範囲

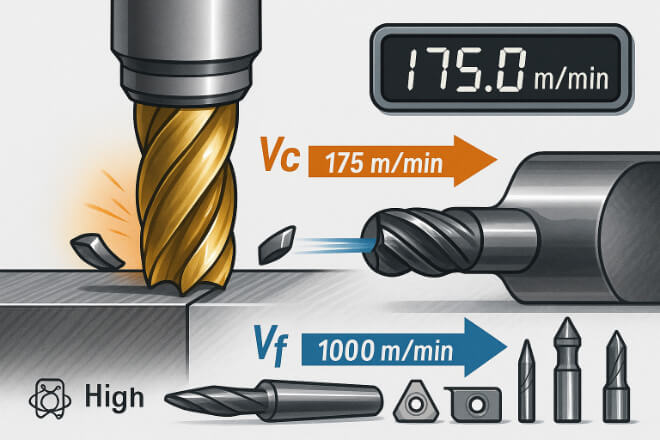

機械加工の世界では、切削速度は単なる数値ではなく、生産性、工具寿命、そして部品の品質に直接影響します。タングステンカーバイド切削工具を使用する際には、適切な切削速度範囲を理解することが重要です。適切な範囲を誤ると、過熱、工具の摩耗、表面仕上げの悪化などの問題が発生します。適切な範囲を選定すれば、高精度、低コスト、そしてスムーズな加工が可能になります。このブログでは、超硬工具における切削速度の仕組み、切削速度に影響を与える要因、そして様々な材料における目標とする範囲について解説します。切削速度とは?切削速度とは、工具の刃先が材料表面を移動する速度です。[…]