炭化タングステンの優れた耐久性を支える科学

産業界において、機械や工具は常に応力、摩擦、そして熱にさらされています。これらの条件に耐えられない部品は急速に摩耗し、ダウンタイムや高額な交換コストにつながります。そのため、多くの企業は、卓越した耐久性で知られる素材であるタングステンカーバイドに頼っています。この記事では、タングステンカーバイドの優れた強度、他のほとんどの素材よりも長持ちする理由、そしてタングステンカーバイドを使用することで産業界が得るメリットについて説明します。タングステンカーバイドとは?タングステンカーバイドは、タングステン(W)と炭素(C)の原子から構成される化合物です。この2つの原子が結合すると、非常に硬く高密度な材料になります。ほとんどの工業用タングステンカーバイド部品には、通常[…]のような金属バインダーも含まれています。

耐摩耗性のために炭化タングステンが選ばれる理由

多くの産業において、機械部品は摩擦、衝撃、熱、腐食による絶え間ない摩耗にさらされています。部品の摩耗が早すぎると、高額なダウンタイムが発生し、生産性が低下する可能性があります。そのため、多くの企業がタングステンカーバイドに注目しています。タングステンカーバイドは、優れた耐摩耗性と長寿命で知られる素材です。このガイドでは、タングステンカーバイドとは何か、なぜ摩耗に非常に効果的なのか、どこで使用されているのか、そして意思決定者がタングステンカーバイドから最大限の価値を引き出す方法について説明します。タングステンカーバイドとは?タングステンカーバイドは、タングステンと炭素原子からなる化合物です。これらの原子は、ほぼ[…]と同等の極めて高い硬度を生み出す結合状態にあります。

タングステンカーバイド摩耗部品とは?完全ガイド

機械が常に摩擦、衝撃、摩耗にさらされる業界では、設備の効率的な稼働を維持することが日々の課題となっています。こうした過酷な環境におけるパフォーマンスを変革した解決策の一つが、タングステンカーバイド摩耗部品の活用です。これらの部品は、従来の鋼製または合金製の部品よりも長寿命で、高負荷に耐え、損傷に強いように設計されています。意思決定者にとって、タングステンカーバイド摩耗部品とは何か、どこで使用されているか、そしてどのように選定すればよいかを理解することは、生産性の向上とダウンタイムの削減の鍵となります。タングステンカーバイド摩耗部品とは?タングステンカーバイド摩耗部品は、タングステンと炭素原子の化合物から作られ、金属結合剤(多くの場合[…])で結合された機械部品です。

タングステンカーバイドワイヤーカッター

ワイヤーカットは、製造業、電気工事、建設業など、多くの業界で一般的な作業です。市場には様々な種類のワイヤーカッターがありますが、タングステンカーバイド製のワイヤーカッターは、その強度、精度、耐久性において際立っています。長期間にわたって信頼性の高い切断性能を求める企業にとって、これらのツールは賢明な投資となります。この記事では、タングステンカーバイド製ワイヤーカッターとは何か、なぜ標準的なカッターよりも優れているのか、その産業用途、そして最良の結果を得るための選び方とメンテナンス方法について説明します。タングステンカーバイド製ワイヤーカッターとは?タングステンカーバイド製ワイヤーカッターは、手工具または機械に取り付けるタイプのカッターで、刃先はタングステンカーバイドで補強されています。タングステンカーバイド[…]

金属用タングステンカーバイド切削工具

タングステンカーバイド切削工具は、現代の金属加工において標準となっています。硬質材料への対応力、鋭い刃先維持能力、そして高速加工能力から、製造業者、工場、そして大規模な産業オペレーションにとって不可欠な選択肢となっています。鋼、ステンレス鋼、チタン、合金などの金属を扱う企業にとって、適切な切削工具の使用は、平均的な成果と並外れた成果の違いを生み出す可能性があります。このガイドでは、タングステンカーバイド切削工具が金属加工に最適な理由、その用途、利点、そして最高のパフォーマンスを得るための選定方法とメンテナンス方法について解説します。タングステンカーバイドが金属切削に最適な理由 タングステンカーバイドは[…]

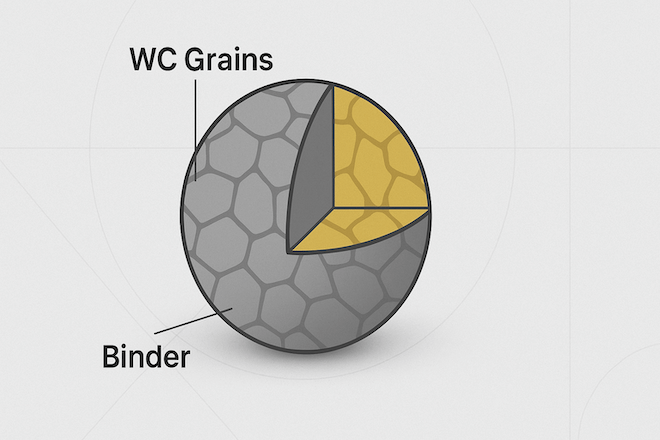

炭化物ボールの性能に対する粒度とバインダーの影響を理解する

タングステンカーバイドボールは、極めて高い硬度、耐摩耗性、長寿命で知られています。しかし、多くの人が気づいていないのは、その性能はタングステンカーバイドの基本素材だけでなく、粒径やバインダー含有量にも左右されるということです。このガイドでは、粒径とバインダーがカーバイドボールの特性、性能、そして最適な用途にどのように影響するかを説明します。タングステンカーバイドボールの粒径とは? 粒径とは、ボール内部のタングステンカーバイド(WC)粒子の平均サイズを指します。通常はミクロン単位で測定されます。細粒:1ミクロン未満 中粒:1~3ミクロン 粗粒:3ミクロン超 重要性:より小さな粒子 → […]