ポンプ、バルブ、シールの摩耗保護用タングステンカーバイド

石油・ガス、化学処理、鉱業、発電といった産業では、ポンプ、バルブ、シールが過酷な条件にさらされています。高圧、研磨粒子、腐食性流体にさらされることが多く、こうした過酷な条件にさらされることで、急速な摩耗と高額なダウンタイムが発生します。世界中で信頼されているソリューションの一つが、タングステンカーバイドです。硬度、耐摩耗性、耐久性に優れたタングステンカーバイドは、重要な部品を保護し、企業のメンテナンスコストの削減と設備寿命の延長に貢献します。この記事では、ポンプ、バルブ、シールの摩耗保護におけるタングステンカーバイドの用途、そのメリット、そして適切なグレードを選ぶための重要な考慮事項について説明します。ポンプ、バルブ、シールに摩耗保護が必要な理由 ポンプ、バルブ、シール […]

木工および切削用途向け超硬摩耗部品

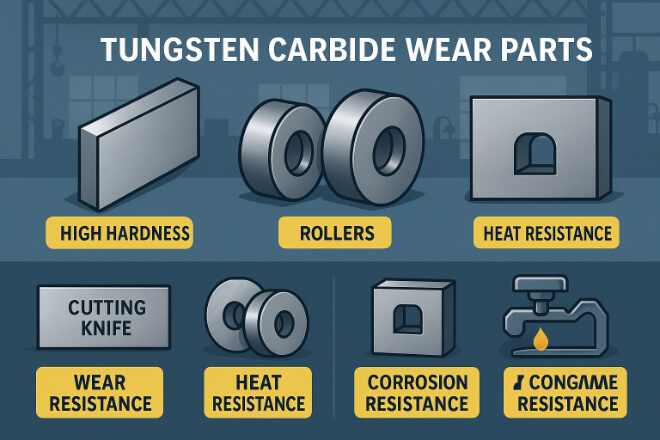

木工・切削加工業界では、効率、精度、耐久性が競争力維持の鍵となります。高性能工具を求める企業にとって、超硬摩耗部品は最適な選択肢となっています。タングステンカーバイドなどの超硬材料で作られたこれらの部品は、耐摩耗性に優れ、切れ味を長持ちさせ、過酷な使用条件でも優れた性能を発揮します。そのため、製材所、家具製造、大規模な切削加工には欠かせない存在となっています。この記事では、超硬摩耗部品とは何か、木工・切削加工でどのように使用されているのか、そしてなぜメーカーにとってこれほど大きな価値をもたらすのかを探ります。超硬摩耗部品とは?超硬摩耗部品は、通常、タングステンカーバイドなどの非常に硬い材料で作られた部品で、ボンドで接合されています。[…]

製紙、繊維、包装機械における炭化タングステン

今日の製造業において、製紙、繊維、包装業界の企業は激しい競争に直面しています。長時間稼働し、高品質の製品を生産し、コストを抑えられる機械が求められています。最大の課題の一つは、機械部品の摩耗への対処です。ここで、タングステンカーバイド製の摩耗部品が重要な役割を果たします。タングステンカーバイドは、その硬度、強度、耐摩耗性、耐熱性、耐腐食性で知られています。これらの特性により、機械が過酷な条件下で稼働する業界に最適です。この記事では、製紙、繊維、包装機械におけるタングステンカーバイドの用途、そしてなぜそれが[…]

金属成形およびスタンピングにおける超硬摩耗部品の用途

金属成形・スタンピングの世界では、機器は極限まで酷使されます。高圧、反復運動、そして絶え間ない摩擦により、一般的な工具材料は急速に摩耗してしまいます。そのため、超硬摩耗部品は多くの製造企業から信頼される選択肢となっています。硬度、耐摩耗性、長寿命で知られる超硬部品は、ダウンタイムの削減と生産効率の向上に貢献します。この記事では、超硬摩耗部品とは何か、なぜ金属成形・スタンピングに最適なのか、そしてこれらの工程でどのような用途で使用されているのかを説明します。超硬摩耗部品とは?超硬摩耗部品は、タングステン粉末と炭化タングステンを混合して作られる材料であるタングステンカーバイドで作られた部品です。[…]

石油・ガス業界における炭化タングステン摩耗部品の利用方法

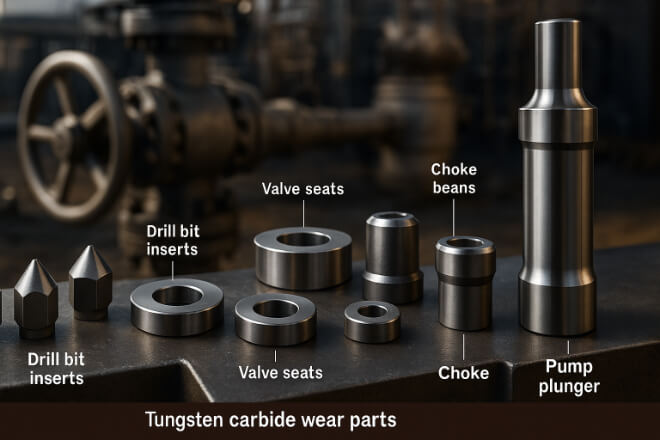

タングステンカーバイド摩耗部品は、石油・ガス業界において極めて重要です。掘削リグ、ポンプ、バルブ、処理装置などの過酷な条件下での稼働時間を延ばす役割を果たしています。この業界の意思決定者にとって、これらの部品がどのように、そしてなぜ使用されているかを理解することで、適切なサプライヤーの選定、機器の性能向上、メンテナンスコストの削減に役立ちます。この記事では、石油・ガス業界におけるタングステンカーバイド摩耗部品の独自の役割について、その特性から主要な用途やメリットまで解説します。また、これらの部品を賢く購入するための方法についても考察します。タングステンカーバイド摩耗部品とは?タングステンカーバイド摩耗部品は、タングステンカーバイド粉末を混合して作られた部品です[…]

鉱業における炭化タングステン摩耗部品

鉱業は世界で最も過酷な産業の一つです。機器は毎日、高圧、高熱、そして摩耗性の高い条件下で稼働し、限界まで酷使されています。このような環境では、工具の故障はコストのかかるダウンタイムや生産性の低下につながる可能性があります。そこで、タングステンカーバイド製の摩耗部品が不可欠となります。タングステンカーバイドは、極めて高い硬度、耐摩耗性、そして靭性で知られる素材です。鉱業で使用すると、機械の寿命が延び、稼働速度が向上し、全体的なメンテナンスコストが削減されます。この記事では、鉱業におけるタングステンカーバイド製摩耗部品の役割、その利点、用途、そして選定時に考慮すべき要素について説明します。タングステンカーバイド製摩耗部品とは?タングステンカーバイド[…]

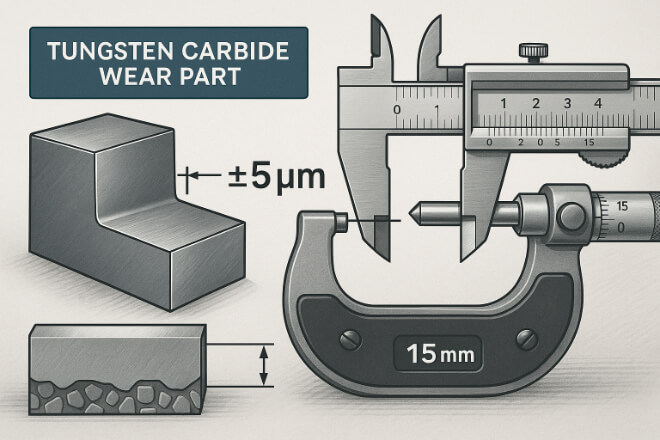

超硬摩耗部品製造における精密公差

現代の製造業において、精密公差は単なる技術的な詳細ではなく、ビジネス上の強みとなります。超硬摩耗部品が使用される業界では、わずかな寸法誤差であっても、摩耗の進行を早め、ダウンタイムの延長、そしてコスト増加につながる可能性があります。鉱業、石油・ガス、自動車、航空宇宙産業など、どのような用途の工具を製造する場合でも、厳格な公差を満たすことで、長い工具寿命、安定した性能、そして顧客の信頼を確保できます。この記事では、精密公差の意味、超硬摩耗部品の製造における重要性、主な課題、そして適切なプロセスと技術を用いて企業がどのように精密公差を達成できるかについて説明します。精密公差とは?精密公差とは、部品の[…]における許容される変動の限界です。

タングステンカーバイド摩耗部品のカスタマイズ:設計のヒントと標準

鉱業、石油・ガス、建設、製造業などの業界では、タングステンカーバイド製の摩耗部品は、設備の効率的な稼働を維持するために不可欠です。これらの部品は、極度の圧力、高温、そして絶え間ない摩擦にさらされます。標準部品も入手可能ですが、多くの企業は独自の運用ニーズを満たすためにカスタム設計を求めています。摩耗部品をカスタマイズすることで、企業はパフォーマンスを向上させ、ダウンタイムを削減し、交換コストを削減することができます。このガイドでは、設計のヒントや、意思決定者が知っておくべき業界標準など、タングステンカーバイド製の摩耗部品をカスタマイズする方法を説明します。摩耗部品にタングステンカーバイドを選ぶ理由 タングステンカーバイドは、その優れた硬度、靭性、耐摩耗性から選ばれています。鋼鉄と比較して、過酷な環境でもはるかに長持ちします。[…]

焼結、研削、コーティング:摩耗部品製造の内側

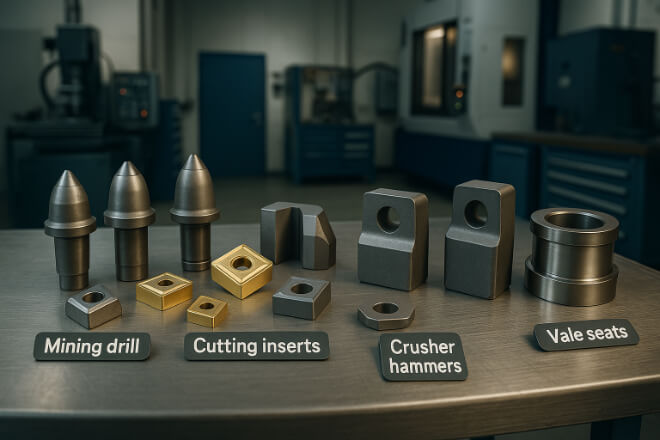

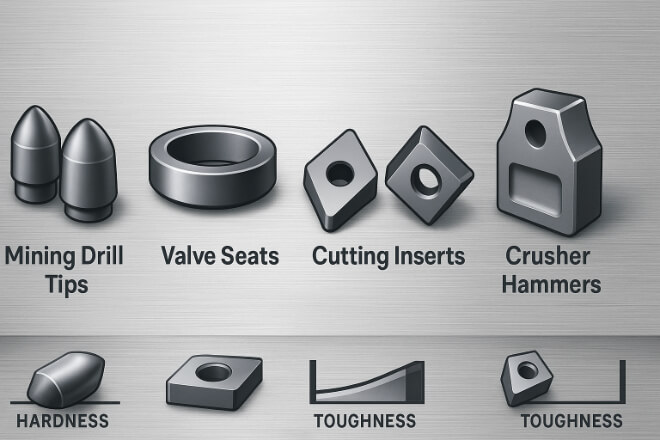

摩耗部品は、鉱業、石油・ガス、金属加工、建設などの産業において不可欠です。これらの部品は、極度の高温、高圧、そして絶え間ない摩擦にさらされます。こうした過酷な条件に耐えるために、メーカーは焼結、研削、コーティングといった高度なプロセスを用いて、強度、靭性、耐久性の適切なバランスを備えた部品を製造しています。この記事では、これら3つの重要なステップをそれぞれ簡潔かつ明確に解説します。適切なサプライヤーの選定や製造品質の理解を目指す意思決定者にとって、このガイドは役立つでしょう。摩耗部品とは?摩耗部品とは、機械や工具の摩耗に耐えるように設計された部品です。例としては、鉱山用ドリルビット、切削工具インサート、破砕機などが挙げられます。[…]

炭化タングステン摩耗部品の製造方法

炭化タングステン摩耗部品は、鉱業、石油・ガス、金属切削、建設などの産業において不可欠です。これらの部品は、硬度、耐摩耗性、そして過酷な作業条件下での長寿命という理由から選ばれています。意思決定者にとって、炭化タングステン摩耗部品の製造方法を理解することは、サプライヤー、品質管理、そしてコストに関するより良い選択に役立ちます。この記事では、そのプロセスを簡単な手順で説明し、原料のタングステンがどのように高性能な摩耗部品へと変化するかを示します。炭化タングステン摩耗部品とは?炭化タングステン摩耗部品は、摩耗、衝撃、高温に耐えるように作られた部品です。例としては、鉱業用ドリルチップ、破砕機用ハンマー、バルブシート、切削インサートなどが挙げられます。これらは特殊な[…]