摩耗部品に適した炭化タングステングレードの選び方

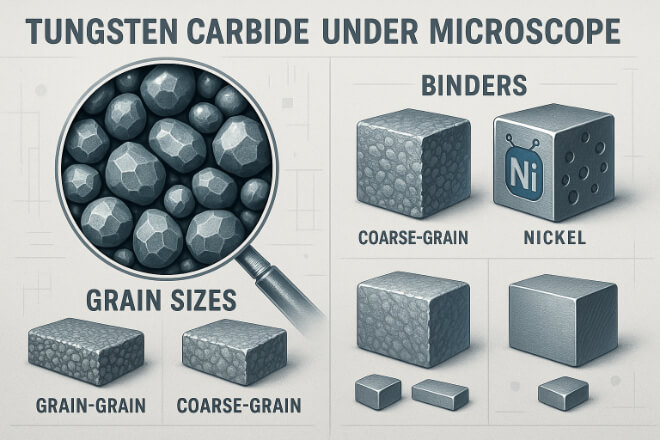

タングステンカーバイドの摩耗部品は、工具が激しい摩耗、熱、または衝撃にさらされる業界で使用されています。しかし、すべてのタングステンカーバイドが同じというわけではありません。異なるグレードは、異なる作業条件に対応するために作られています。不適切なグレードを選択すると、早期の故障、コストの増加、ダウンタイムにつながる可能性があります。適切なグレードを選択することで、工具寿命と性能を最大限に高めることができます。このガイドでは、グレードの意味、違い、そして用途に最適なグレードを選択する方法について説明します。このガイドの目的は、特に製造業、鉱業、石油・ガス、金属成形、その他の重工業の意思決定者にとって、このプロセスをシンプルかつ明確にすることです。タングステンカーバイドグレードについて タングステンカーバイドグレードとは […]

超硬摩耗部品の再生とリサイクル

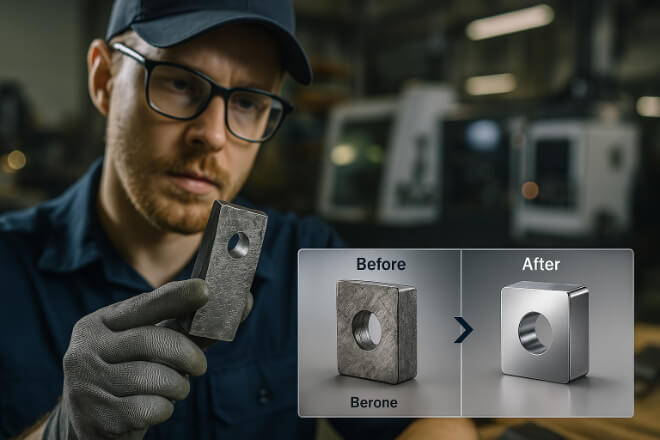

タングステンカーバイド摩耗部品は、その強度、硬度、耐摩耗性で知られています。鉱業、石油・ガス、製造業、木工など、多くの業界で使用されています。しかし、最も頑丈なカーバイド部品であっても、時間の経過とともに摩耗します。企業は、新品の部品に交換する代わりに、再生またはリサイクルを選択することで、コスト削減と環境保護を実現できます。この記事では、再生とリサイクルの仕組み、重要性、そして業界の意思決定者がカーバイド部品から最大限の価値を引き出すために知っておくべきことについて説明します。カーバイド摩耗部品の再生が重要な理由再生とは、使用済みの摩耗部品を元の形状、サイズ、性能に戻すことです。摩耗した部品を廃棄するのではなく、熟練した[…]

タングステンカーバイドの摩耗部品の交換時期と方法

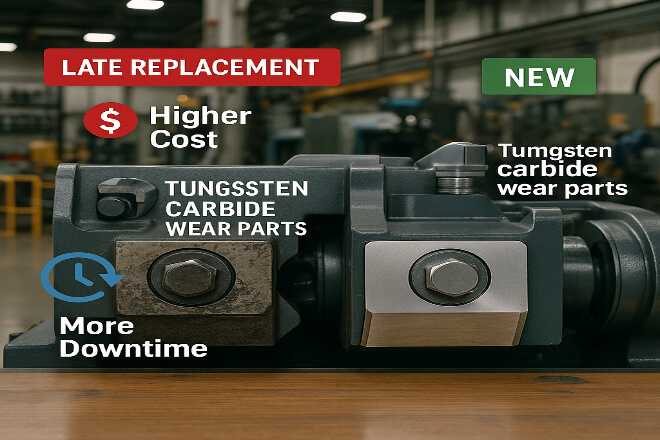

タングステンカーバイド製の摩耗部品は、その高い硬度、耐摩耗性、そして長寿命から、鉱業、石油・ガス、製造業、金属加工などの業界で使用されています。鋼鉄よりもはるかに強度が高いにもかかわらず、いずれは摩耗したり故障したりします。意思決定者にとって、これらの部品の交換時期を把握することは、コストのかかるダウンタイムを回避し、他の機械部品を保護し、生産効率を維持するための鍵となります。このガイドでは、交換が必要な兆候、適切な交換方法、そして新しい部品の寿命を延ばす方法について説明します。交換時期が重要な理由 タングステンカーバイド製の摩耗部品の交換時期が遅すぎると、次のような問題が発生する可能性があります。予定外のダウンタイム 修理費用の増加 損傷[…]

摩耗部品の一般的な故障とその防止方法

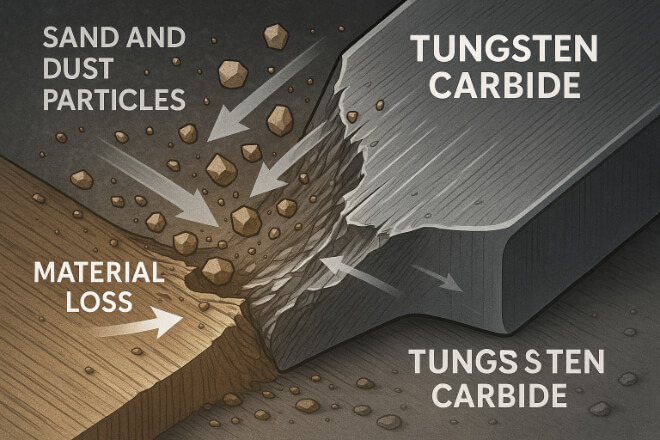

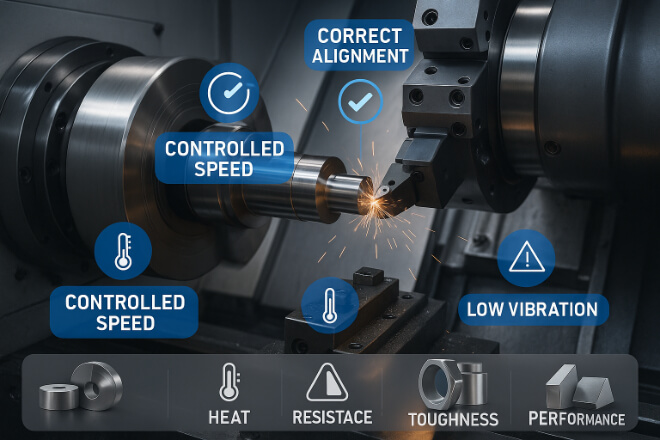

摩耗部品は、重機、製造設備、採掘ツール、その他多くの産業システムにおいて重要な部品です。摩耗部品は、稼働中に最も大きな応力と摩耗に耐え、機械の他の部分を損傷から保護するように設計されています。しかし、炭化タングステン、硬化鋼、セラミックといった最も強度の高い材料であっても、適切な選定、メンテナンス、使用を怠ると故障する可能性があります。故障は、コストのかかるダウンタイムを引き起こすだけでなく、高価な機械に損傷を与える可能性があります。この記事では、摩耗部品が故障する最も一般的な原因と、これらの問題を防ぐ方法について解説し、意思決定者が機器をより長く、より効率的に稼働させるのに役立ちます。アブレシブ摩耗 1)。概要:アブレシブ摩耗は、[…]などの硬い粒子が摩耗することで発生します。

タングステンカーバイド摩耗部品の寿命を延ばす方法

タングステンカーバイド製摩耗部品は、高い硬度、耐摩耗性、そして長寿命で知られています。鉱業、石油・ガス、金属成形、製造業など、過酷な環境で稼働する機器を扱う業界で使用されています。しかし、最高のタングステンカーバイド製部品であっても、適切に使用・メンテナンスされなければ、早期に故障する可能性があります。意思決定者にとって、これらの部品の寿命を延ばすことは、交換費用の節約だけでなく、ダウンタイムの削減、生産性の向上、そして機械への投資の保護にもつながります。この記事では、タングステンカーバイド製摩耗部品の寿命を延ばすための簡単で実用的な手順を説明します。用途に適したグレードを選ぶ すべてのタングステンカーバイドが[…]