タングステンカーバイド摩耗部品メーカー

When machines run day after day in heavy industries like mining, oil and gas, metalworking, or agriculture, the weakest link is often the part that wears down first. To avoid frequent breakdowns, many companies depend on tungsten carbide wear parts. These parts are known for their strength, hardness, and ability to resist wear better than steel or other common materials. Behind every carbide wear part is a manufacturer whose skills, technology, and quality control directly affect performance. For decision-makers, choosing the right tungsten carbide wear parts manufacturer is as important as selecting the material itself. In this article, we’ll look at: The role of carbide wear parts in modern industries. […]

超硬摩耗部品の特徴と用途

In industries where machines face friction, pressure, and abrasion, the choice of material makes all the difference. Carbide wear parts, especially those made with tungsten carbide, are known for their strength, hardness, and durability. These parts are found in mining drills, oilfield valves, machining tools, woodworking blades, and even in food processing equipment. For decision-makers, understanding the features and applications of carbide wear parts is not just a technical matter—it directly affects efficiency, costs, and long-term competitiveness. Key Features of Carbide Wear Parts Carbide wear parts stand out because of their unique combination of material properties. Unlike steel or ceramics alone, carbide is made by combining tungsten carbide powder with […]

タングステンカーバイド摩耗部品を使用する産業

Tungsten carbide wear parts are some of the most trusted components in modern industry. Known for their hardness, wear resistance, and long life, they are essential wherever equipment faces friction, heavy loads, or abrasive environments. From drilling oil wells to stamping automotive parts, tungsten carbide helps businesses run more efficiently and reduce downtime. This article explores the key industries that rely on tungsten carbide wear parts, why they are used, and what decision-makers should know to get the most value from them. Mining and Construction Mining is one of the toughest environments for machinery. Tools like drill bits, crushers, and cutting tools face constant abrasion from rock and ore. Tungsten […]

超硬摩耗部品の故障防止

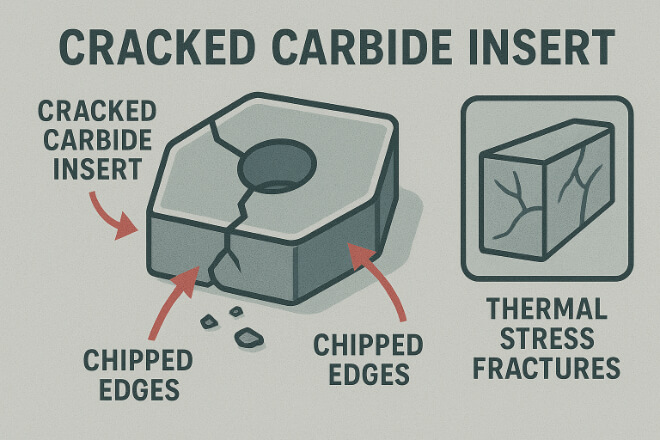

Carbide wear components are widely used in industries like mining, oil and gas, metal forming, woodworking, and more. They are chosen because of their hardness, wear resistance, and long service life. However, even the best carbide components can fail if they are not designed, handled, or maintained correctly. For decision-makers, understanding how failures happen—and how to prevent them—is key to keeping machines running smoothly and avoiding costly downtime. This article explores the common causes of failures in carbide wear components and provides practical strategies to extend their life. Why Carbide Wear Components Fail Carbide is strong, but it is not indestructible. Failures usually occur because of: Excessive stress or impact […]

現代の超硬部品における高度なバインダーシステム

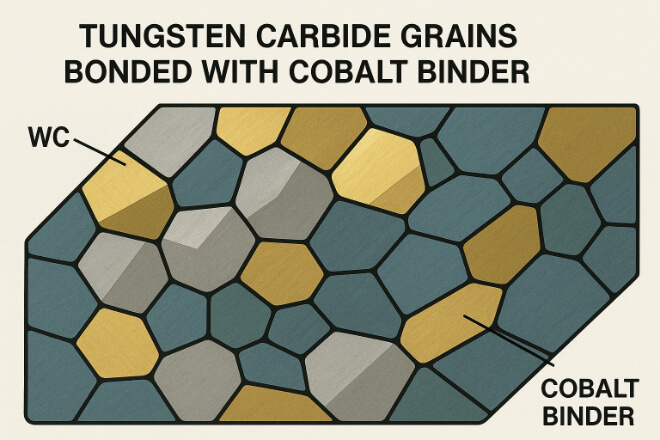

Tungsten carbide has become one of the most important materials in industrial manufacturing. Its hardness and ability to withstand extreme wear make it the go-to choice for cutting tools, mining components, and wear-resistant parts. But what often goes unnoticed is the role of binder systems. Without the right binder, carbide parts would be too brittle or inconsistent for real-world use. This article explores advanced binder systems in modern carbide parts—why they matter, how they work, and what decision-makers in heavy industries need to know. What Are Binder Systems in Carbide? Carbide parts are not made of tungsten carbide alone. They are a composite material, combining hard carbide grains (usually tungsten […]