ダウンタイムの最小化:タングステンカーバイドボールの長期的な価値

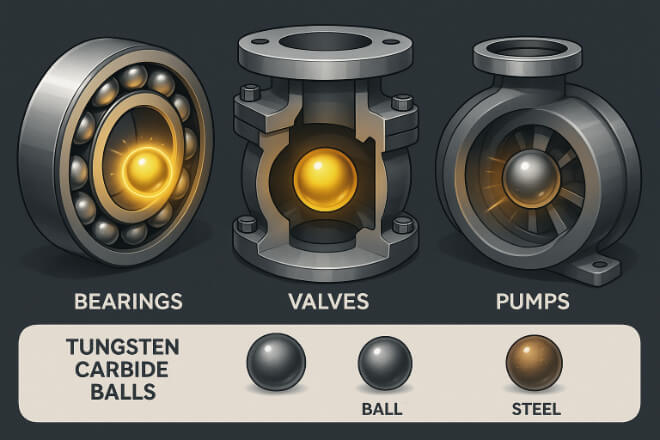

In industries like mining, oil & gas, aerospace, and heavy machinery, every hour of downtime costs money. One small component can often be the difference between smooth operations and unexpected shutdowns. Tungsten carbide balls are one such component, and their long-term value lies in how they reduce downtime, extend equipment life, and lower total operating costs. This article explains why tungsten carbide balls are the smarter investment, how they deliver long-term value, and what decision-makers should consider when choosing them. The Role of Tungsten Carbide Balls in Industry Tungsten carbide balls are widely used in bearings, valves, pumps, and ball screws because they handle extreme stress without deforming. Their hardness, […]

タングステンカーバイドボールの寿命と費用対効果

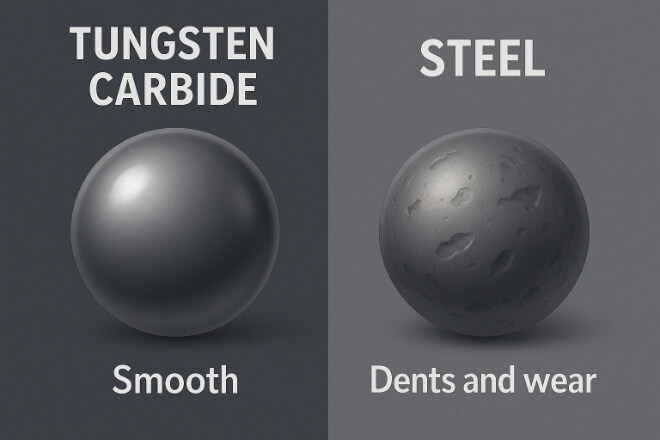

Decision-makers in industries such as mining, oil & gas, aerospace, and precision manufacturing know the challenge of balancing upfront tool cost with long-term performance. Tungsten carbide balls have become a trusted choice because they combine long lifespan with strong cost-benefit. While the initial purchase may be higher than steel or ceramic balls, the overall value makes them a smart investment. This article explores the durability, cost-effectiveness, and return on investment (ROI) of tungsten carbide balls, helping leaders understand when and why they should make the switch. The Durability Advantage of Tungsten Carbide Balls The biggest reason for choosing tungsten carbide is its hardness and resistance to wear. With hardness levels […]

他の高摩耗材料よりも炭化タングステンを選ぶべき理由

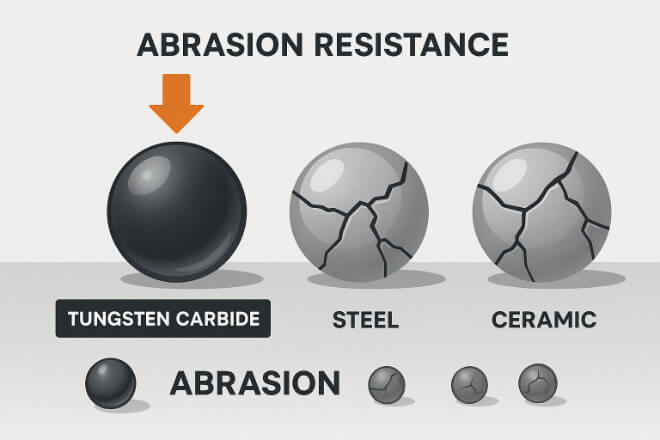

In heavy industries, decision-makers often face one key challenge: selecting the right material for parts that must withstand constant wear, heat, or pressure. Materials like hardened steel, ceramics, Stellite, and composites are widely used, but tungsten carbide often stands out. Knowing when to choose tungsten carbide over other high-wear materials can help save costs, improve productivity, and extend equipment life. This article explains the performance factors, compares tungsten carbide with alternatives, and highlights real-world scenarios where carbide is the best choice. Hardness and Wear Resistance The primary reason companies pick tungsten carbide is its exceptional hardness. With a hardness rating close to diamond (around 1600–2000 HV on the Vickers scale), […]

タングステンカーバイドボールとスチールボールの性能比較

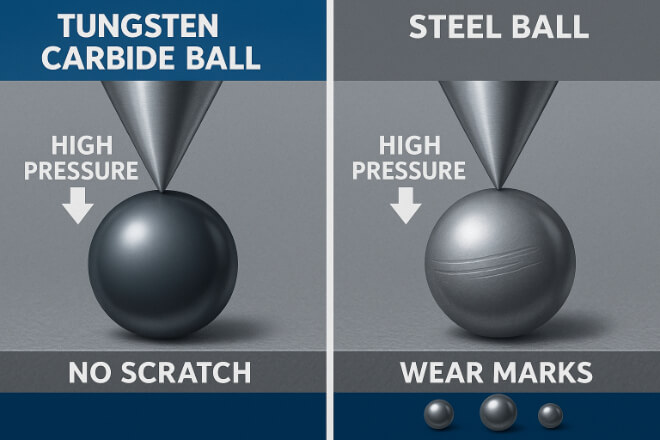

In many industries, from bearings and valves to milling media and aerospace components, balls made from different materials are used to handle load, friction, and wear. Among the options, tungsten carbide balls and steel balls are the most common. At first glance, they may look similar, but their performance is very different. Choosing between them depends on your application, cost targets, and long-term goals. In this article, we will compare tungsten carbide balls vs steel balls in terms of hardness, density, wear resistance, cost, and applications. For decision-makers, this comparison helps in making the right investment in material that matches performance needs. Hardness and Wear Resistance The first big difference […]

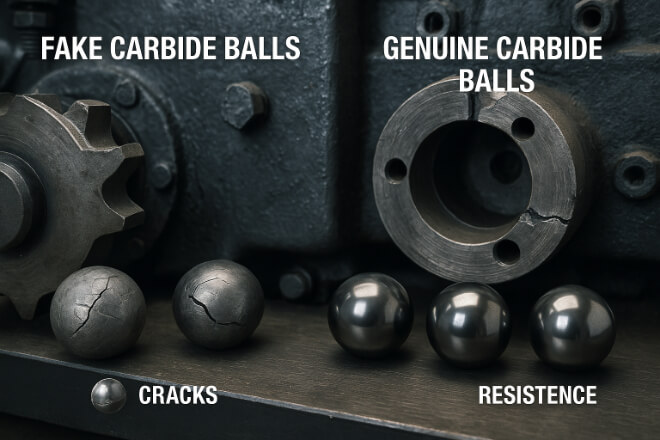

偽造超硬ボールの見分け方:重量と密度の計算

In global industries, from bearings to valves and milling media, tungsten carbide balls play a vital role. Because of their high hardness, wear resistance, and density, they are often preferred over steel or ceramic balls. However, the popularity of carbide balls has also created a problem: counterfeit products. Fake carbide balls may look similar to real ones, but they often lack the required hardness, density, and durability. Using counterfeit parts can lead to serious problems—equipment breakdown, higher downtime, and costly failures. For decision-makers, the ability to spot counterfeit carbide balls early is critical. One of the most reliable ways to check authenticity is by looking at weight and density calculations. […]