ベアリング、バルブ、流量計に使用されるタングステンカーバイドボール

Tungsten carbide balls may be small, but in industries where precision and durability matter, they are essential. From bearings that keep machines running smoothly, to valves that control flow under extreme pressure, to flowmeters that provide accurate readings, tungsten carbide balls deliver performance where steel or other materials often fail. This article explains why they are used, what benefits they bring, and how decision-makers can weigh cost versus performance when selecting materials. Why Tungsten Carbide Balls Are Preferred The first question for any industrial buyer is: why use tungsten carbide instead of steel? The answer lies in the material’s unique properties: Hardness close to diamond (above 90 HRA). High wear […]

タングステンカーバイドボールの主な産業用途

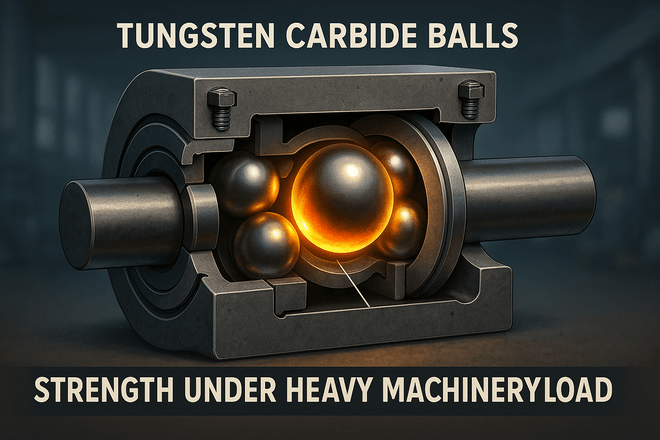

Tungsten carbide balls are small in size, but they deliver big value in many industrial sectors. Known for their extreme hardness, high wear resistance, and ability to work under heavy loads, they are chosen over steel balls when performance and reliability are critical. For decision-makers, understanding where these balls are used can help plan better investments and reduce long-term costs. This article explains the top applications of tungsten carbide balls in industry, showing how they support bearings, valves, ball screws, grinding operations, oil & gas tools, and precision instruments. Bearings for Heavy Loads and Long Life One of the largest uses of tungsten carbide balls is in bearings. Bearings with […]

タングステンカーバイドボールとその用途に関する6つの重要な事実

Tungsten carbide balls are small, but they play a very big role in modern industries. Known for their hardness, strength, and ability to last longer than steel, these balls are used in everything from bearings and valves to grinding media. For decision-makers in manufacturing, mining, oil & gas, and precision engineering, understanding the value of tungsten carbide balls helps in planning for both performance and cost efficiency. In this article, we will look at six key facts about tungsten carbide balls, explain how they are used, and show why they are such a strong choice in demanding applications. Tungsten Carbide Balls Are Extremely Hard The first fact about tungsten carbide […]

タングステンカーバイドボールの持続可能/リサイクル可能な側面

Tungsten carbide balls are widely used in bearings, valves, grinding, milling, and precision tools because of their extreme hardness, strength, and wear resistance. While they offer long service life compared to steel or ceramic alternatives, decision-makers today must also ask: Are tungsten carbide balls sustainable? Can they be recycled to reduce environmental impact? This article explores the sustainability side of tungsten carbide balls—covering recyclability, environmental benefits, and how industries can reduce costs while supporting greener practices. Why Sustainability Matters in Carbide Materials Global industries such as automotive, aerospace, mining, and oil & gas rely heavily on carbide balls. At the same time, environmental regulations and corporate sustainability goals are putting […]

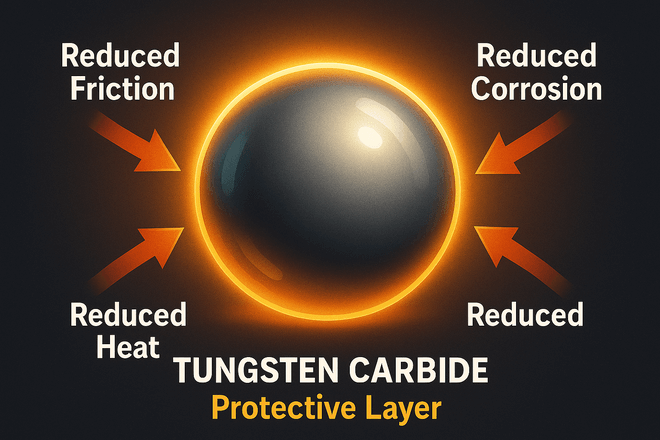

超硬ボールの性能向上のためのコーティングと表面処理

In modern industries, tungsten carbide balls are widely used in bearings, valves, pumps, grinding, and precision equipment. Their natural hardness and wear resistance already make them strong performers. But in high-stress environments, coatings and surface treatments take carbide ball performance to the next level. This article explores how coatings improve performance, which coating types are most effective. And why decision-makers in industries like oil & gas, mining, aerospace, and manufacturing should consider surface treatments for better ROI. Why Coatings Matter for Carbide Balls Even though tungsten carbide balls are much harder and more durable than steel, they still face challenges such as high friction, extreme heat, and corrosion in harsh […]