適切なタングステンカーバイドシールリンググレードの選び方

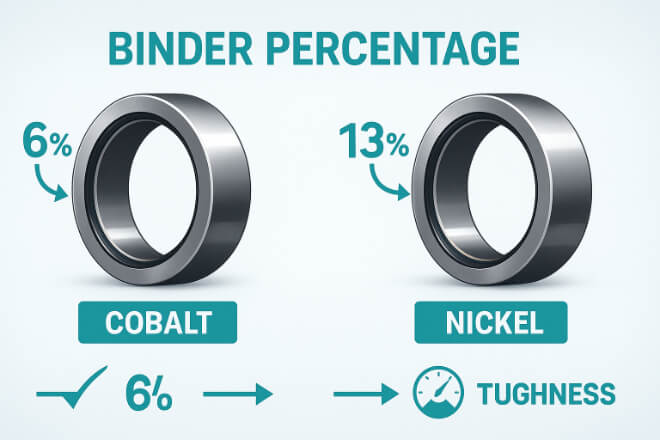

In pumps, turbines, and compressors, seal rings are essential. They stop leaks, protect equipment, and keep operations safe. But not all tungsten carbide seal rings are the same. They come in different grades, each designed for a specific condition. For decision-makers, choosing the correct grade can make the difference between smooth performance and costly breakdowns. This guide explains how to select the right tungsten carbide seal ring grade based on environment, binder type, pressure, and chemical exposure. What Is a Tungsten Carbide Seal Ring Grade? A grade refers to the specific formula of tungsten carbide and binder used to make the seal ring. By changing binder type or percentage, the […]

ニッケル結合タングステンカーバイドシールリングとコバルト結合タングステンカーバイドシールリング

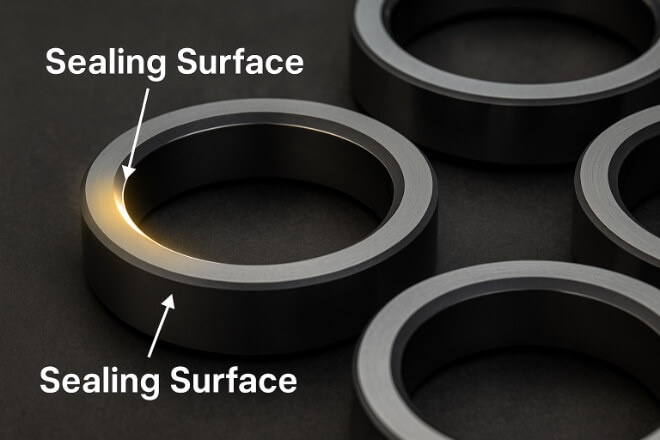

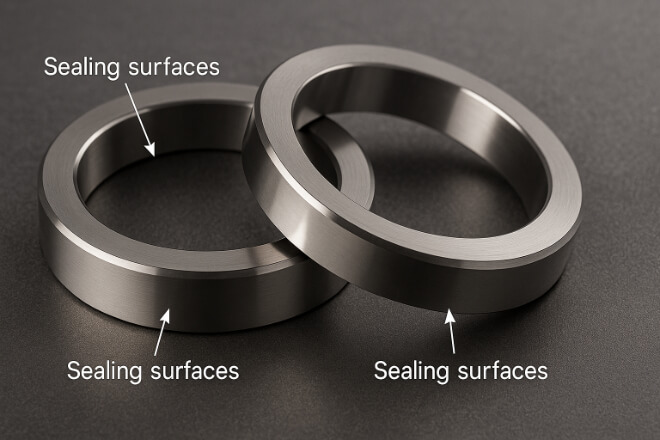

In pumps, compressors, turbines, and mixers, seal rings are small but essential parts. They prevent leaks, protect systems, and reduce downtime. Choosing the right seal ring material is not only an engineering decision but also a business one. Among many options, tungsten carbide seal rings are trusted worldwide. But there are two main types: nickel-bonded and cobalt-bonded. Both have unique properties, and the right choice depends on the application. This article compares the two, explaining their strengths, differences, and best uses, helping decision-makers select the right solution for long-term performance. What Are Tungsten Carbide Seal Rings? Tungsten carbide is made by combining tungsten and carbon powder, pressed together with a […]

炭化タングステンシールリングの耐腐食性と耐熱性

In pumps, compressors, and turbines, seal rings are small but vital parts. They stop leaks, protect equipment, and keep systems safe. But not all seal materials can survive the same harsh conditions. For industries dealing with chemicals, seawater, or high temperatures, the best choice is often the tungsten carbide seal ring. Tungsten carbide is famous for its hardness, but two of its most valuable properties are corrosion resistance and heat resistance. These features make it suitable for industries such as oil & gas, chemical processing, marine systems, and power plants. This article explains how tungsten carbide seal rings resist corrosion and heat, why these properties matter, and what decision-makers should […]

タングステンカーバイドシールリングと他のシール材の比較

Seal rings are small components, but they protect machines from leaks, failures, and costly downtime. Choosing the right seal material is one of the most important decisions for industries working with pumps, compressors, turbines, and mixers. Many materials are available—stainless steel, ceramics, silicon carbide, carbon graphite, and tungsten carbide. Each has strengths and weaknesses. For decision-makers, the question is: Which material delivers the best performance for your operations? This article compares tungsten carbide seal rings with other common sealing materials, explaining their properties, advantages, and limits to help companies make informed choices. What Are Tungsten Carbide Seal Rings? Tungsten carbide seal rings are made by combining tungsten and carbon, with […]

炭化タングステンシールリングの主な性能特性

In pumps, compressors, turbines, and mixers, the seal system plays a critical role. A poor seal can lead to leaks, downtime, or even accidents. For industries that deal with high pressure, speed, or aggressive fluids, choosing the right seal material is vital. One of the most trusted solutions is the tungsten carbide seal ring. Known for its hardness and durability, this component offers properties that outperform many other sealing materials. For decision-makers, knowing the key performance properties of tungsten carbide seal rings helps ensure reliable operation and cost savings. What Are Tungsten Carbide Seal Rings? Tungsten carbide seal rings are mechanical sealing parts made by combining tungsten and carbon, usually […]