炭化タングステンシールリングのライフサイクルコスト分析

In industries such as oil and gas, marine, chemical, and power generation, seal rings are small but vital components. Their job is to prevent leaks, protect equipment, and ensure safety. Many companies focus only on the upfront price of seal rings when making purchase decisions. But the true cost is not just the purchase price—it is the life cycle cost. This article explores how tungsten carbide seal rings perform when analyzed over their full life cycle. We will look at initial cost, maintenance, downtime, service life, and recycling value to help decision-makers see why tungsten carbide is often the smarter investment. What Is Life Cycle Cost Analysis? Life cycle cost […]

炭化タングステンシールリングが熱応力と機械的衝撃に耐える仕組み

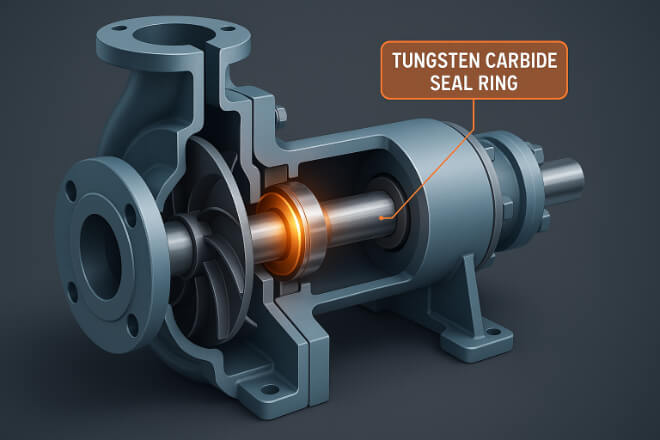

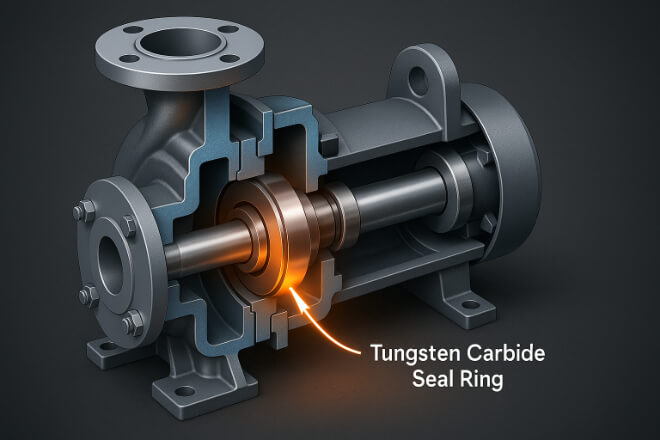

In heavy industries such as power generation, oil and gas, marine, and chemical processing, equipment is constantly exposed to heat, pressure, and mechanical shock. If seals fail in these systems, the consequences are costly downtime, safety risks, and lower efficiency. To solve these challenges, companies rely on tungsten carbide seal rings. This article explains how tungsten carbide seal rings are designed to resist thermal stress and mechanical shock, and why they are the trusted choice for high-demand industries. What Are Tungsten Carbide Seal Rings? Tungsten carbide seal rings are precision components used in pumps, compressors, and valves. They are made from tungsten carbide, a material created by combining tungsten and […]

タングステンカーバイドシールリングの寿命を延ばすメンテナンスのヒント

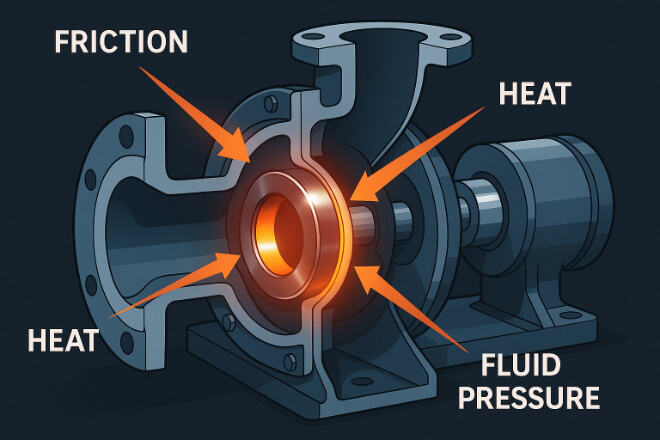

In industries like power generation, oil and gas, chemical plants, and marine operations, tungsten carbide seal rings are critical components. They keep pumps, compressors, and valves running safely under high pressure, heat, and corrosive conditions. However, even the strongest material will wear out if not maintained properly. For companies, extending the life of these seal rings means fewer shutdowns, lower costs, and more reliable equipment. This article provides practical maintenance tips to help decision-makers ensure that tungsten carbide seal rings last as long as possible. Why Maintenance Matters for Tungsten Carbide Seal Rings Although tungsten carbide is extremely hard and durable, seal rings still face challenges: Friction from constant rotation […]

発電・海洋機器における炭化タングステンシールリング

Power generation and marine equipment face some of the toughest working conditions in industry. High pressure, heat, water, and corrosive environments place extreme demands on sealing components. If seals fail, the result is downtime, costly repairs, and even safety risks. For this reason, many companies rely on tungsten carbide seal rings. These rings combine strength, wear resistance, and durability to provide reliable sealing in harsh operating conditions. This article explores how tungsten carbide seal rings are used in power generation and marine equipment, what makes them strong, and why they are the right choice for companies looking to reduce risks and improve efficiency. What Are Tungsten Carbide Seal Rings? Tungsten […]

タングステンカーバイドシールリングを使用した高圧シールソリューション

High-pressure systems are found in many industries, from oil and gas to chemical plants and power generation. These systems require reliable sealing components to prevent leakage, avoid downtime, and maintain safety. One of the best solutions for this challenge is the tungsten carbide seal ring. Known for its strength, wear resistance, and durability under extreme pressure, these rings are trusted by industries worldwide. This article explains why tungsten carbide seal rings are the preferred choice for high-pressure sealing, what makes them strong, and how they add value to industrial operations. What Are Tungsten Carbide Seal Rings? A tungsten carbide seal ring is a circular component made from tungsten carbide, a […]