高圧ポンプに最適なタングステンカーバイドシールリング

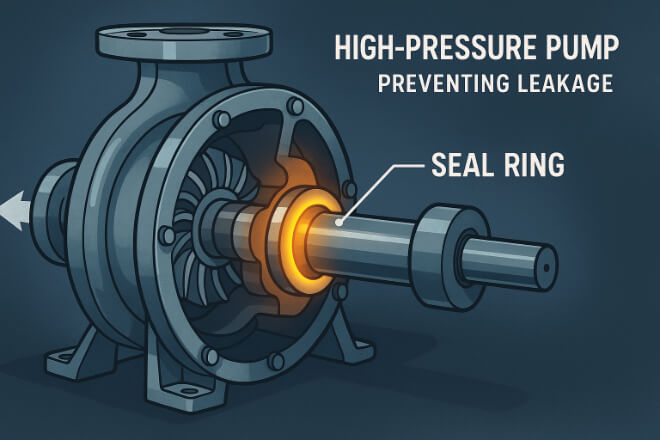

High-pressure pumps are vital in industries such as oil and gas, power generation, chemical plants, and marine systems. These pumps must operate under extreme pressure and sometimes corrosive conditions. The seal ring is one of the most important parts of these pumps because it prevents leakage, protects equipment, and ensures safety. When choosing the right seal ring, tungsten carbide stands out as one of the best materials. This article explores why tungsten carbide seal rings are ideal for high-pressure pumps, the different grades available, and what decision-makers should consider when selecting them. Why High-Pressure Pumps Need Strong Seal Rings High-pressure pumps face conditions that can destroy weak seals: Extreme pressure […]

ヘキソロイ シールリングとタングステンカーバイド シールリング: どちらが優れていますか?

Seal rings are small but critical parts in pumps, compressors, turbines, and marine systems. The right choice of seal ring material can mean the difference between smooth operation and costly downtime. Among the many options, Hexoloy (a type of sintered silicon carbide) and tungsten carbide are two of the most commonly used. Both materials are strong, durable, and suitable for high-demand industries. But they are not the same. Each has strengths and weaknesses that make it better for certain applications. This article compares Hexoloy vs tungsten carbide seal rings, helping decision-makers choose the right option for their systems. What Is Hexoloy? Hexoloy is a trademarked form of sintered silicon carbide. […]

メカニカルシール技術における将来の材料動向

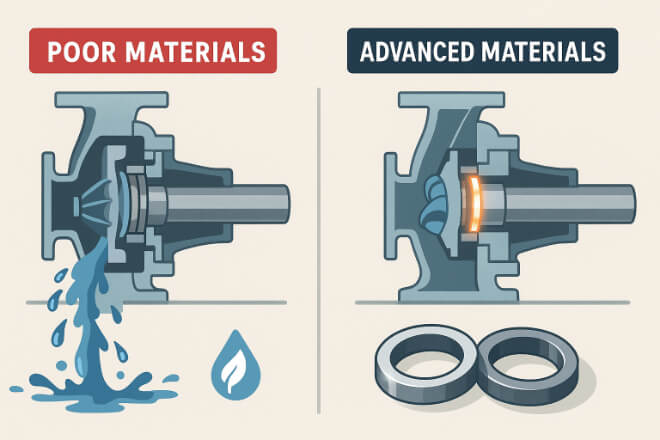

Mechanical seals are small but critical components used in pumps, compressors, turbines, and mixers. They prevent leaks, improve efficiency, and protect equipment in industries such as oil & gas, chemical processing, water treatment, and power generation. As machines face harsher environments, higher speeds, and stricter safety rules, traditional seal materials like stainless steel and carbon graphite are no longer enough. The future of seal technology depends on advanced materials that provide greater strength, wear resistance, and chemical stability. This article explores the future material trends in mechanical seal technology, showing decision-makers what to expect and how to prepare. Why Material Choice Matters in Mechanical Seals Seal materials directly affect performance, […]

持続可能なシーリングソリューションにおけるタングステンカーバイドシールリングの役割

Sustainability is no longer just a trend—it is a requirement for industries like oil and gas, marine, power generation, and chemical processing. Every component in a system now plays a role in improving efficiency, reducing waste, and lowering environmental impact. Seal rings are small parts but have a big effect. When they fail, companies face downtime, leaks, and safety risks. Among many options, tungsten carbide seal rings stand out because they not only provide strength and durability but also support sustainable sealing solutions. This article explains how they contribute to sustainability and why they are the smart choice for decision-makers. What Makes Sealing Solutions Sustainable? A sustainable sealing solution is […]

炭化タングステンシールリングを炭化シリコンに交換することのメリットとデメリット

Seal rings are vital for pumps, compressors, turbines, and other rotating equipment in industries like oil and gas, power generation, marine, and chemical plants. The right seal ring material can decide whether a system works smoothly or fails early. Two of the most common materials are tungsten carbide and silicon carbide. Many companies consider replacing tungsten carbide seal rings with silicon carbide to improve performance or reduce costs. But is this always the right choice? This article explores the advantages and disadvantages of making such a switch, helping decision-makers evaluate the long-term impact. What Are Tungsten Carbide Seal Rings? Tungsten carbide seal rings are made from tungsten and carbon with […]