産業機器向け高温タングステンカーバイドシールリング

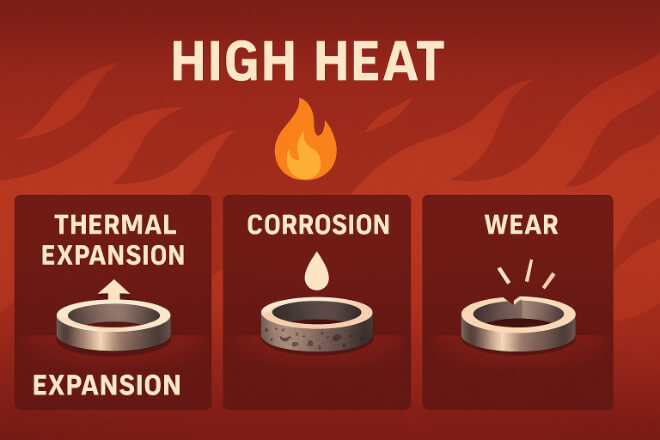

Industrial equipment in oil and gas, power generation, chemical plants, and marine systems often works under high-temperature and high-pressure conditions. In such environments, sealing systems must not only stop leaks but also resist heat, wear, and chemical attack. A failure in seals can lead to dangerous leaks, downtime, and costly repairs. One of the most reliable materials for these demanding conditions is tungsten carbide. This article explains why high-temperature tungsten carbide seal rings are essential for industrial equipment, their advantages, and how they deliver long-term value for companies. The Challenge of High-Temperature Sealing Seals exposed to high temperatures face unique problems: Thermal expansion → Materials expand and contract, causing cracks […]

タングステンカーバイドシールリングが水中ポンプに不可欠な理由

Submersible pumps are widely used in industries such as oil and gas, mining, power generation, marine, and wastewater treatment. These pumps operate underwater or in fluid-filled environments, often under high pressure, heat, and corrosive conditions. One of the most important components in these pumps is the seal ring, which prevents leakage and protects the system. For these demanding applications, tungsten carbide seal rings are the most reliable choice. This article explains why they are essential for submersible pumps, their advantages, and what decision-makers need to know before selecting them. The Role of Seal Rings in Submersible Pumps Seal rings have the critical job of: Preventing water, oil, or chemicals from […]

油田および石油化学用途向けタングステンカーバイドシールリング

The oilfield and petrochemical industries run some of the most demanding systems in the world. Pumps, compressors, valves, and drilling equipment must work under high pressure, heat, and corrosive fluids. A failure in sealing systems can lead to downtime, safety risks, and financial loss. This is why many companies choose tungsten carbide seal rings. This article explains how tungsten carbide seal rings perform in oilfield and petrochemical applications, their unique properties, and why they are the best option for long-term reliability and cost savings. Why Seal Rings Matter in Oilfield and Petrochemical Equipment Seal rings are critical in protecting equipment against: Leakage of oil, gas, or chemicals Erosion from abrasive […]

過酷な環境における炭化タングステンシールリングの耐薬品性

In industries such as oil and gas, chemical processing, marine, and power generation, sealing systems face harsh and corrosive environments. Equipment often operates under high pressure, heat, and exposure to aggressive fluids. If seals fail, the result is leakage, downtime, and expensive repairs. For this reason, many companies rely on tungsten carbide seal rings. This article explores why tungsten carbide is valued for its chemical resistance, how it performs in harsh environments, and what decision-makers should consider when choosing seal rings. What Makes a Seal Ring Chemically Resistant? A chemically resistant seal ring is one that can withstand attack from corrosive fluids without losing strength or shape. In harsh environments, […]

タングステンカーバイドシールリングがメカニカルシールの信頼性を向上させる仕組み

Mechanical seals are essential in pumps, compressors, turbines, and marine systems. Their main role is to stop leaks, protect equipment, and keep systems running safely. However, the reliability of mechanical seals depends heavily on the quality of their sealing faces. Among the many materials available, tungsten carbide seal rings stand out as one of the best choices for industries that need durability and efficiency. This article explains how tungsten carbide seal rings improve mechanical seal reliability, reduce failures. And add long-term value for industries such as oil and gas, power generation, chemical processing, and marine equipment. What Are Tungsten Carbide Seal Rings? Tungsten carbide is a compound of tungsten and […]