タングステンカーバイドシールリングとセラミックシールリングの詳細な比較

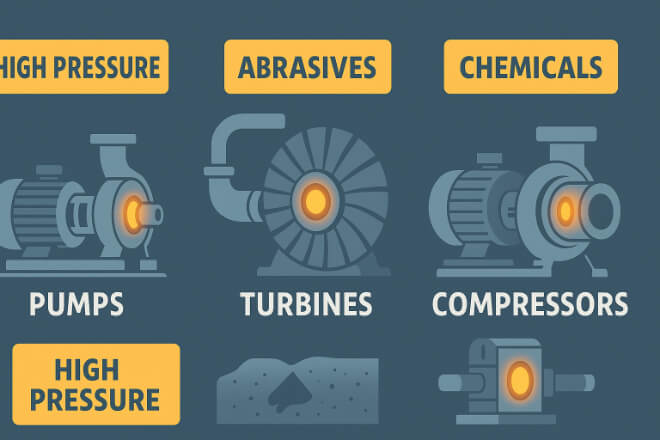

In pumps, compressors, turbines, and marine equipment, seal rings are critical for preventing leakage and protecting machinery. Choosing the right material for seal rings has a direct impact on equipment life, reliability, and maintenance cost. Two of the most common materials used are tungsten carbide and ceramic. Both materials have strong advantages, but they are not the same. This article provides a detailed comparison between tungsten carbide seal rings and ceramic seal rings, focusing on their properties, performance, and applications. What Are Tungsten Carbide Seal Rings? Tungsten carbide is a compound of tungsten and carbon, bonded with cobalt or nickel. It is widely used in mechanical seals because of its: […]

タングステンカーバイドシールリングが回転機器のダウンタイムを削減する方法

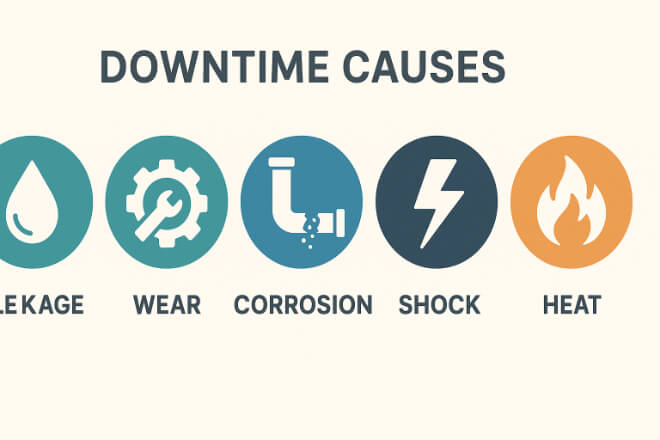

Rotating equipment—such as pumps, compressors, turbines, and marine systems—is the backbone of many industries, including oil and gas, chemical plants, marine operations, and power generation. One of the biggest challenges in keeping this equipment running is seal failure. When seals fail, downtime increases, costs rise, and operations are put at risk. This is why many companies choose tungsten carbide seal rings. Known for their durability and reliability, these rings help extend the life of mechanical seals and reduce downtime. This article explains how tungsten carbide seal rings achieve this, and why they are a smart choice for decision-makers. Why Downtime Happens in Rotating Equipment Downtime often results from seal problems […]

海洋およびオフショア事業におけるタングステンカーバイドシールリングの利点

Marine and offshore operations are some of the toughest industrial environments. Equipment such as pumps, compressors, propulsion systems, and drilling platforms must operate continuously while exposed to seawater, pressure, vibration, and corrosive fluids. In such settings, sealing systems play a critical role in preventing leaks and protecting machinery. Among the many materials available, tungsten carbide seal rings have proven to be one of the most reliable choices. This article explains their benefits, performance advantages, and why decision-makers in the marine and offshore sectors should consider them for long-term efficiency and safety. Why Sealing Is Critical Offshore Marine and offshore systems work in harsh environments where failure can be costly and […]

遠心ポンプシールシステムにおける炭化タングステンシールリング

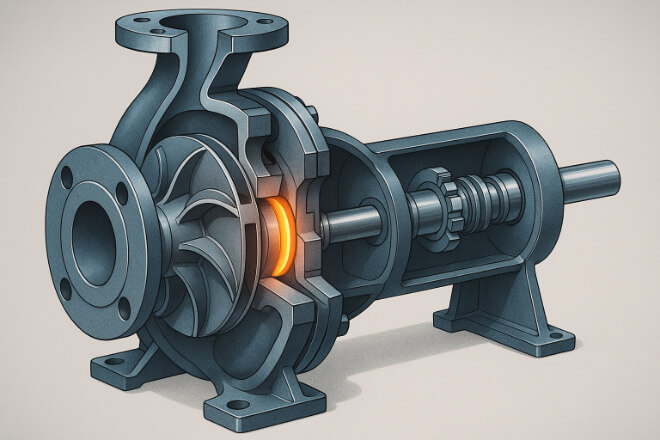

Centrifugal pumps are the backbone of many industries, including oil and gas, power generation, marine, and chemical processing. Their reliability depends heavily on the sealing system, which prevents fluid leakage and protects pump components. At the heart of these systems are seal rings. Among all materials, tungsten carbide seal rings stand out for their ability to handle high pressure, heat, and corrosive fluids. This article explains their role in centrifugal pumps, their advantages, and why decision-makers should choose them for long-term performance. Why Sealing Is Critical in Centrifugal Pumps Centrifugal pumps operate by moving fluids with rotating impellers. The seal system must: Prevent fluid leakage along the pump shaft. Handle […]

独自のエンジニアリングニーズに応えるカスタムメイドのタングステンカーバイドシールリング

In many industries, sealing systems are not standard—they are designed to meet unique engineering needs. Equipment in oil and gas, chemical plants, marine operations, and power generation often faces conditions that off-the-shelf seal rings cannot handle. This is why many companies turn to custom-made tungsten carbide seal rings. This article explains why customization matters, what benefits tungsten carbide provides, and how decision-makers can ensure they select the right seal rings for their equipment. Why Custom Seal Rings Are Needed Standard seals may work in some applications, but many industries require special designs to handle: Extreme pressure or temperature conditions. Fluids with abrasive particles. Aggressive chemicals or seawater. Complex pump, turbine, […]