再生可能エネルギー機器における炭化タングステンシールリング

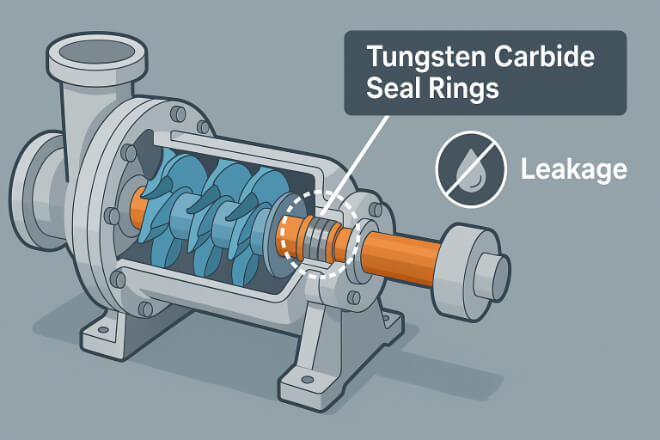

Renewable energy systems—such as wind turbines, hydroelectric plants, solar farms with pumps, and geothermal systems—operate under tough environmental conditions. Their components must run for years with minimal maintenance to keep energy production efficient and cost-effective. One critical component is the seal ring. In pumps, turbines, and compressors, seals prevent fluid leaks, protect bearings, and ensure energy efficiency. Among available materials, tungsten carbide seal rings offer superior performance for renewable energy equipment. Why Seal Rings Matter in Renewable Energy Systems Seal failures can: Cause fluid leaks in hydraulic or coolant systems. Increase downtime, reducing energy output. Lead to extra maintenance costs and safety risks. Lower equipment efficiency, wasting renewable energy. Reliable […]

腐食性化学媒体用タングステンカーバイドシールリングの選択

Chemical plants, refineries, marine systems, and power facilities often handle aggressive chemical media—fluids that are highly corrosive or abrasive. Seal rings in pumps, compressors, and turbines must withstand these harsh conditions without leaking or failing. Tungsten carbide seal rings are one of the most reliable solutions. This article explains their advantages, how to select the right grade, and why they deliver long-term value for industrial decision-makers. Challenges of Aggressive Chemical Media Aggressive fluids present unique problems: Strong corrosion → Acids, alkalis, and solvents break down weaker materials. Abrasive particles → Suspended solids wear out seals quickly. High pressure and temperature → Stress causes distortion or cracking. Downtime cost → Seal […]

コンプレッサーおよびターボ機械用タングステンカーバイドシールリング

Compressors and turbo machinery are essential in industries such as oil and gas, chemical processing, marine, and power generation. These machines operate under high pressure, heat, and vibration, and even a small seal failure can lead to expensive downtime and safety risks. To ensure reliable performance, many companies choose tungsten carbide seal rings. This article explains why tungsten carbide is the preferred choice, its advantages over other materials, and best practices for decision-makers. Why Seal Rings Matter in Compressors and Turbo Machinery Seal rings in compressors and turbines perform critical tasks: Prevent leaks of gas, air, or fluids. Protect bearings and rotors from contamination. Reduce friction and wear inside high-speed […]

炭化タングステンシールリングの環境的利点

Industries like oil and gas, marine, chemical, and power generation are under pressure to reduce their environmental impact. Every part of industrial equipment, including sealing systems, can influence sustainability. One material stands out for both performance and environmental benefits: tungsten carbide seal rings. This article explains the environmental advantages of using tungsten carbide seal rings, showing how they help companies cut waste, save resources, and meet sustainability goals. Why Seal Ring Materials Affect the Environment Seal failures and frequent replacements create: Waste → Broken or worn seals end up as scrap. Energy loss → Leaks reduce equipment efficiency. Higher emissions → Downtime or inefficiency leads to extra fuel use. Resource […]

スラリーおよび研磨性流体処理用タングステンカーバイドシールリング

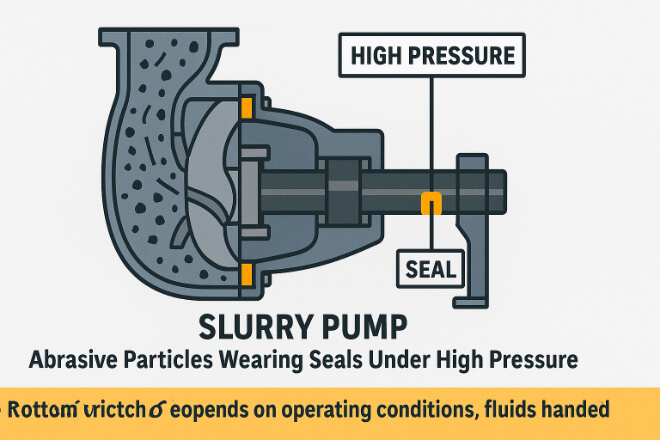

Slurry and abrasive fluids are some of the most challenging materials for industrial pumps, mixers, and turbines. These fluids contain solid particles such as sand, silt, or minerals that can quickly damage equipment. A reliable sealing system is essential to prevent leaks, reduce maintenance, and keep operations running smoothly. Among the materials available, tungsten carbide seal rings are one of the best choices for slurry and abrasive fluid handling. This article explains why, compares them to alternatives, and offers tips for decision-makers. Challenges of Slurry and Abrasive Fluid Handling Abrasive fluids create unique problems for seals and equipment: Severe wear → Solid particles grind against seals, causing rapid damage. High […]