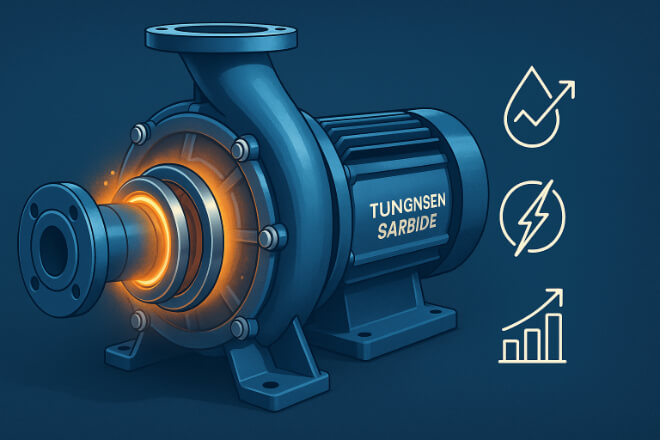

淡水化・汽水ポンプ用タングステンカーバイドシールリング

Desalination and brackish water pumps work under harsh conditions—high salinity, abrasive particles, and constant pressure. Reliable sealing is critical to prevent leaks, maintain efficiency, and reduce downtime. Tungsten carbide seal rings are widely used in these systems because of their durability, corrosion resistance, and long service life. This article explains their advantages, applications, and best practices for decision-makers. Why Desalination and Brackish Water Pumps Need Strong Seals Prevent leaks → Protects expensive equipment and prevents contamination. Maintain pump efficiency → Reliable seals reduce friction and energy waste. Handle high salinity → Saltwater is corrosive to weaker materials. Reduce downtime → Avoid unplanned maintenance and expensive repairs. Protect the environment → […]

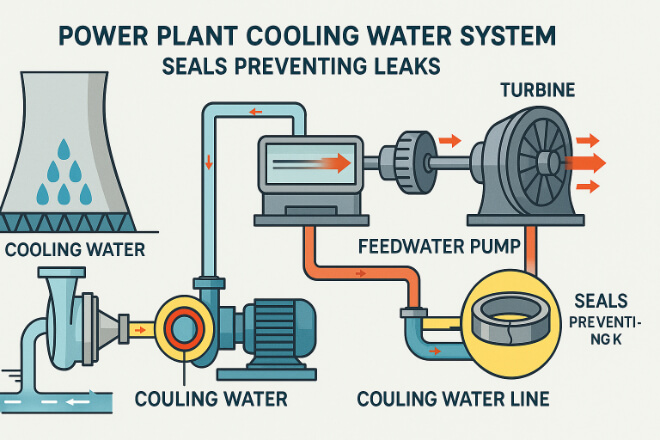

発電所冷却水システム用タングステンカーバイドシールリング

Power plants rely on cooling water systems to manage heat and keep turbines, pumps, and generators running safely. Any leak or failure in these systems can lead to downtime, efficiency loss, or environmental damage. Tungsten carbide seal rings are one of the most reliable materials for pumps and compressors in cooling water systems. This article explains why they are essential, their benefits, and how to use them effectively. Why Cooling Water Systems Need Reliable Seals Prevent leaks → Protect equipment and reduce water loss. Maintain efficiency → Proper seals help pumps operate at full performance. Reduce downtime → Reliable seals minimize unplanned maintenance. Avoid contamination → Prevents cooling water from […]

炭化タングステンシールリングの一般的な故障モードとその回避方法

Tungsten carbide seal rings are widely used in pumps, compressors, turbines, and marine equipment. Their strength, hardness, and corrosion resistance make them a top choice for mechanical seals in industries like oil and gas, chemical processing, power generation, and marine systems. However, even tungsten carbide seals can fail if used incorrectly or in harsh conditions without proper care. Understanding common failure modes helps decision-makers reduce downtime, cut costs, and improve safety. Why Seal Ring Failures Are Costly Unplanned downtime → Production halts, leading to lost revenue. Expensive repairs → Pumps or compressors may need replacement parts. Environmental risks → Leaks can cause spills or contamination. Safety hazards → High-pressure leaks […]

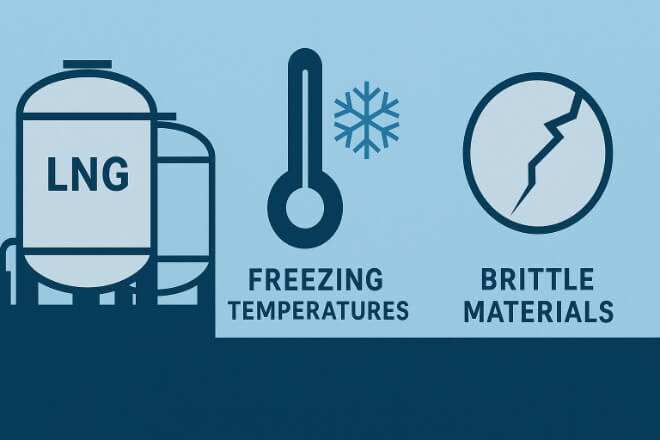

極低温および極寒環境用タングステンカーバイドシールリング

Cryogenic and extreme cold environments—such as liquefied natural gas (LNG) plants, aerospace testing facilities, scientific labs, and deep-sea systems—require sealing solutions that can perform reliably at very low temperatures. In these environments, materials become brittle, fluids behave differently, and any failure can cause costly downtime or safety hazards. Tungsten carbide seal rings are a trusted choice for pumps, compressors, and turbines operating in these harsh conditions. This article explains their properties, advantages, applications, and best practices for decision-makers. Challenges of Cryogenic and Extreme Cold Conditions Operating at temperatures as low as -196 °C (-320 °F) creates challenges: Material brittleness → Metals and plastics can crack or deform. Thermal contraction → […]

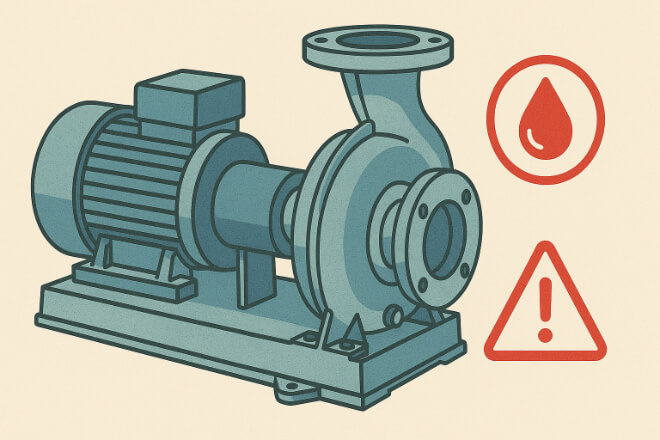

How Tungsten Carbide Seal Rings Support Leak-Free Pump Operation

Pumps are critical components in industries like oil and gas, power generation, chemical processing, and marine operations. A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable. Tungsten carbide seal rings are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers. Why Leak-Free Pump Operation Matters Prevents fluid loss → Protects resources and reduces waste. Maintains efficiency → Pumps perform better without pressure loss. Reduces maintenance costs → Fewer failures mean fewer repairs. Protects the environment → Prevents spills of hazardous materials. Ensures safety […]