パルプ、紙、黒液処理における超硬シールリング

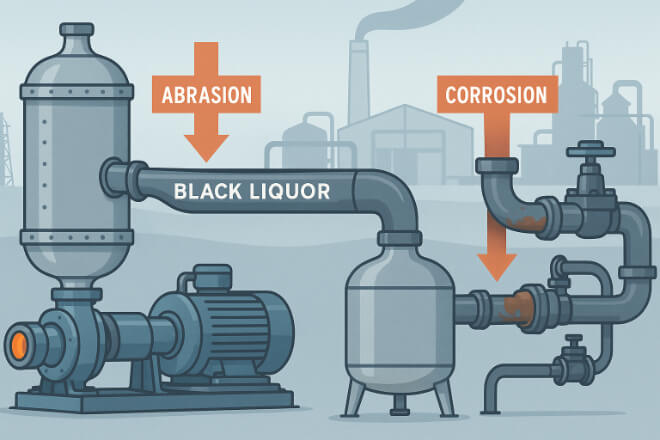

パルプ・製紙業界は、最も要求の厳しい産業環境の一つです。これらの工場では、ポンプ、ミキサー、パイプラインなどで研磨性のパルプ繊維、腐食性化学物質、高圧黒液を取り扱っています。わずかな漏れでも生産に支障をきたし、設備を損傷したり、環境に悪影響を与えたりする可能性があります。この分野では、カーバイドシールリングが頼りになるソリューションとなっています。優れた硬度、耐腐食性、そして長寿命を誇ります。意思決定者にとって、カーバイドシールへの投資は、故障の減少、より安全な操業、そしてコスト削減につながります。パルプ・製紙・黒液サービスにおける課題:研磨性のパルプ繊維は、標準的なシールを急速に摩耗させます。パルプ製造の副産物である黒液は、アルカリ性が高く、腐食性が高い性質を持っています。また、薬品回収ボイラーでは高温が問題となります[…]

化学反応器および撹拌機シャフト用超硬シールリング

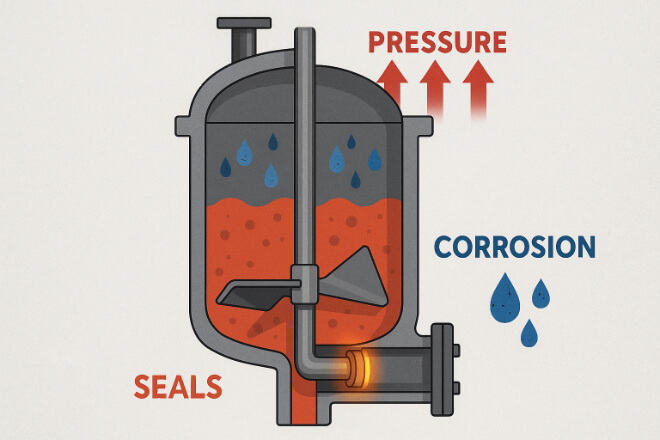

化学プラントでは、反応炉や撹拌機シャフトが過酷な条件下で稼働しています。高圧、腐食性化学物質、そして連続運転を扱っています。たった一度の漏れでも、高額なダウンタイム、製品汚染、さらには安全上の問題を引き起こす可能性があります。カーバイドシールリングは、これらのシステムを保護するための最適な選択肢となっています。この記事では、カーバイドシールリングが化学反応炉や撹拌機シャフトに不可欠な理由、過酷な条件下での性能、そして意思決定者が選定時に考慮すべき点について説明します。化学反応炉と撹拌機の課題:腐食性化学物質はシールを急速に損傷させる可能性があります。高圧と高温は装置に負担をかけます。連続運転は摩耗と摩擦を引き起こします。安全規制では、危険な漏れを防ぐための信頼性の高いシールが求められています。従来のシール材は[…]

スラリー輸送および尾鉱パイプライン用超硬シールリング

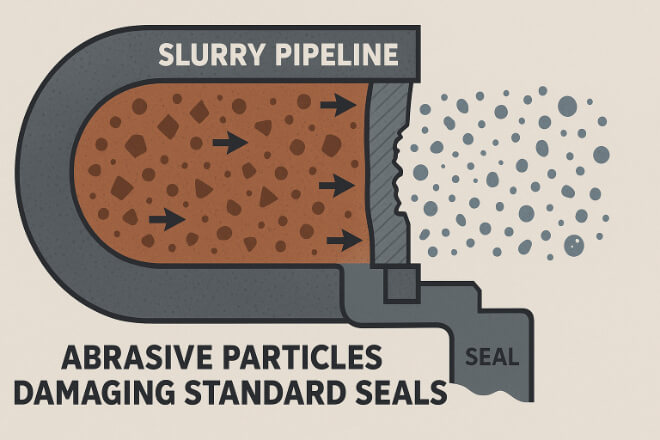

鉱業および選鉱業において、スラリー輸送システムと尾鉱パイプラインは、水、岩石、砂などの研磨性のある混合物を輸送します。これらの流体は機器にとって過酷な条件を伴います。ポンプ、バルブ、パイプラインは、絶え間ない摩耗と圧力に耐えなければなりません。これらのシステムで最も重要な部品の一つがカーバイドシールリングです。カーバイドシールリングは、漏れを防ぎ、摩耗を軽減することでポンプとバルブを保護します。その硬度、強度、耐腐食性により、これらの過酷な環境に最適です。意思決定者にとって、カーバイドシールリングを選択することは、耐用年数の延長、故障の減少、そして投資収益率の向上を意味します。スラリーおよび尾鉱輸送における課題 スラリーと尾鉱には特有の問題があります。研磨粒子は[…]

船舶バラスト水および冷却システムにおける超硬シールリング

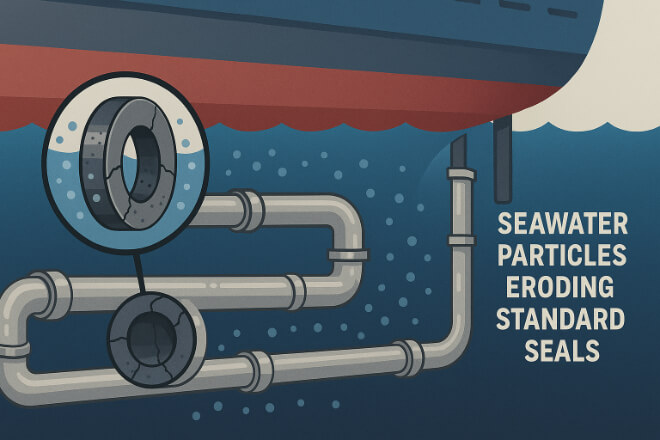

現代の船舶は、安定性を確保し、エンジンや補機類を保護するための冷却回路としてバラスト水に依存しています。これらのシステムは、塩分を多く含み、研磨性があり、時には堆積物で汚染された生の海水を絶えず汲み上げています。小さな漏れやシールの不具合は、操業の中断、メンテナンス費用の増加、環境規制違反につながる可能性があります。こうした過酷な用途において、超硬シールリングは信頼性の高い選択肢として際立っています。超硬シールリングは、従来の素材では実現できない硬度、耐腐食性、そして長期安定性を兼ね備えています。シールを損傷する海洋運航上の課題:海水による腐食は、一般的な金属シールを時間の経過とともに劣化させます。バラストタンク内の微細な砂やゴミは、シール面をサンドペーパーのように傷めます。積み込み/積み下ろし時の圧力変化は、ポンプ部品に負担をかけます。[…]

製油所チャージポンプおよびボトムポンプ用カーバイドシールリングの選定

製油所のチャージポンプとボトムポンプは過酷な条件下で稼働します。高圧、高温、そして腐食性の高い流体を扱います。適切なカーバイドシールリングを選択することは、安全な運転、メンテナンスコストの削減、そしてポンプ寿命の延長に不可欠です。このガイドは、製油所の意思決定者が最適なシールリングを選択できるよう、分かりやすい言葉と明確な手順を用いています。カーバイドシールリングが重要な理由 カーバイドシールリングは、炭化タングステンや炭化ケイ素などの非常に硬い材料で作られています。これらの材料は、鋼やセラミックよりも摩耗、熱、化学的な腐食に優れています。製油所のチャージポンプとボトムポンプにおいて、優れたシールは次のような効果をもたらします。炭化水素の危険な漏洩を防ぐ ポンプのダウンタイムと修理コストを削減する ポンプ効率を向上させる […]