最適な嵌合ペア:タングステンカーバイド vs カーボン vs シリコンカーバイドシール面

Mechanical seals are critical components in pumps, compressors, and mixers. They prevent leaks, protect equipment, and ensure safe operation. The mating pair—the two faces that slide against each other—is one of the most important choices for seal performance. Three popular materials are tungsten carbide, carbon, and silicon carbide. Each has strengths and weaknesses depending on operating conditions. Choosing the best pairing impacts equipment reliability, maintenance cost, and safety. This guide compares tungsten carbide, carbon, and silicon carbide seal faces, showing which pairs work best for different industrial duties. What Makes Mating Pairs Important Friction control: The right combination reduces heat and wear. Leak prevention: Correct pairs maintain tight seals under […]

LNG、極低温、低温用途向け超硬シールリング

Liquefied natural gas (LNG), cryogenic fluids, and other low-temperature applications are critical in energy, chemical, and aerospace industries. These systems operate at extreme cold, where ordinary seal materials can become brittle, shrink, or crack. Seal failure under such conditions can stop operations, cause leaks, or create dangerous situations. Carbide seal rings are engineered to handle these demanding duties. With their hardness, toughness, and resistance to temperature changes, they ensure pumps, compressors, and valves remain reliable. For decision-makers, carbide seals mean fewer breakdowns, safer operations, and long-term cost savings. Challenges in LNG and Cryogenic Applications Extreme cold makes many metals and polymers brittle. Rapid temperature changes cause thermal shock, stressing seals. […]

ターボコンプレッサーおよび真空システム用超硬シールリング

Turbo compressors and vacuum systems are critical in refineries, chemical plants, cleanrooms, and power stations. They manage fast-moving gases, pressure extremes, and sensitive vacuum environments. Even a minor seal leak can stop production, waste energy, or risk contamination. Carbide seal rings provide the reliability these systems demand. Known for their toughness, heat stability, and chemical resistance, they outperform many traditional sealing materials. For operations managers, upgrading to carbide seals can mean fewer failures, smoother processes, and measurable cost savings. Key Challenges in These Systems Extreme rotor speeds generate high friction and surface wear. Rapid pressure shifts stress compressor seals. Corrosive gases or cleaning chemicals attack weaker materials. Vacuum sensitivity requires […]

水中汚水・廃水ポンプ用超硬シールリング

Submersible sewage and wastewater pumps work under harsh and dirty conditions. They handle sludge, grit, sand, and corrosive fluids that quickly damage weak seals. If a pump fails, the result can be costly repairs, environmental hazards, and service disruptions. Carbide seal rings are an ideal choice for these pumps. Their hardness, corrosion resistance, and long lifespan protect pumps from wear and leaks. For decision-makers in municipal services, wastewater treatment plants, and industrial facilities, choosing carbide seals improves reliability and reduces maintenance costs. Challenges in Sewage and Wastewater Pumping Abrasive solids such as sand and grit wear down standard seals. Corrosive liquids damage metals and plastics in long-term use. Continuous operation […]

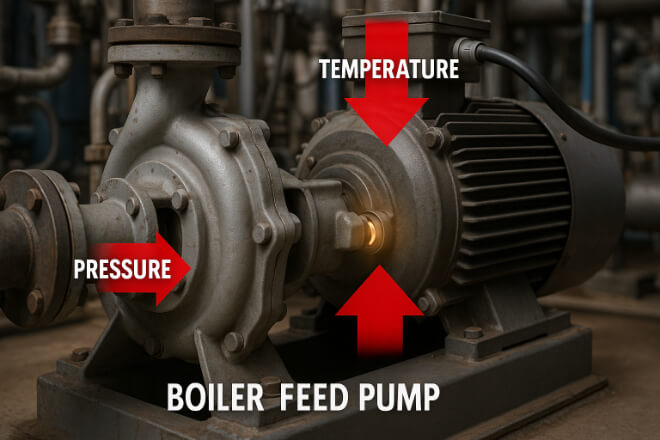

発電所ボイラー給水ポンプ用超硬シールリング

Power plants rely on boiler feed pumps to move water at very high pressure into boilers. These pumps work under extreme heat, pressure, and continuous operation. Even a small seal failure can stop a unit, cause costly repairs, or reduce power generation efficiency. Carbide seal rings have become the preferred choice for these pumps. They provide excellent hardness, toughness, and corrosion resistance. For decision-makers, using carbide seals means fewer shutdowns, safer operations, and better return on investment. Challenges in Boiler Feed Pump Sealing High pressure and temperature can deform or damage weak seals. Continuous operation increases friction and wear. Water impurities or chemical additives can corrode metal components. Unexpected leaks […]