超硬合金面を持つエラストマーの選択:Viton、EPDM、FFKMの検討事項

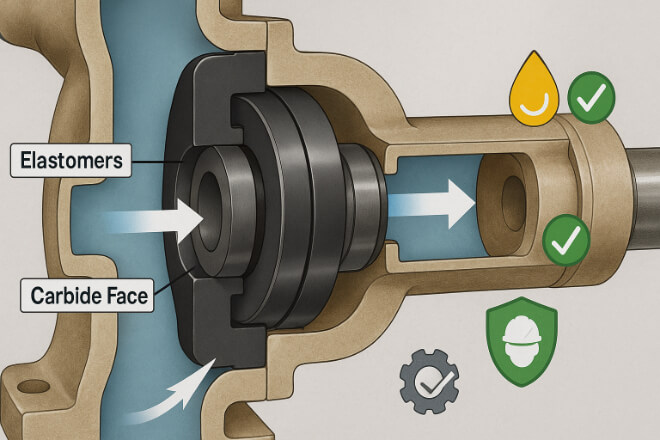

In industrial sealing applications, carbide faces are often paired with elastomers to form reliable seals for pumps, valves, and compressors. Elastomers such as Viton, EPDM, and FFKM offer flexibility, durability, and resistance to various environmental factors. The choice of elastomer plays a crucial role in the performance, longevity, and safety of the sealing system. This guide compares Viton, EPDM, and FFKM elastomers, helping decision-makers choose the best material for their specific needs. We will discuss their properties, advantages, limitations, and how they pair with carbide faces for optimal sealing performance. What Are Elastomers and Why Are They Important? Elastomers are rubber-like materials that can stretch and return to their original […]

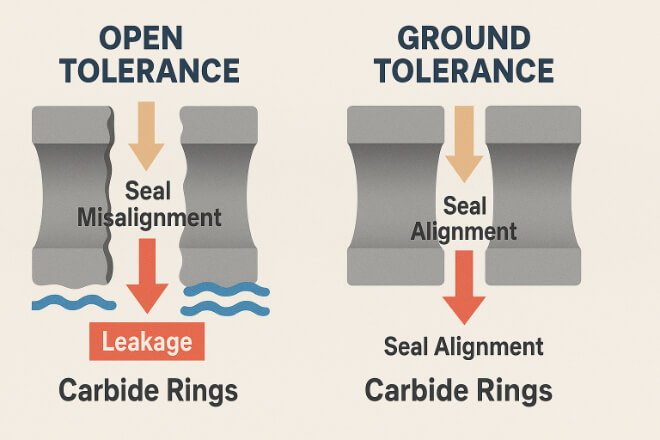

超硬シールリングのオープン許容差と研磨許容差:漏れ制御への影響

Carbide seal rings are critical components used in pumps, compressors, and valves across industries like power generation, chemical processing, and oil & gas. Their primary role is to prevent leaks and maintain pressure integrity within systems. One of the key factors influencing seal performance is tolerance, which refers to the allowable variation in the dimensions of the seal faces. The two main types of tolerance for carbide seal rings are open tolerance and ground tolerance. Understanding the differences between these two types and how they affect leakage control can help decision-makers select the right seals for their applications, ensuring safety and efficiency in their operations. What Are Tolerances and Why […]

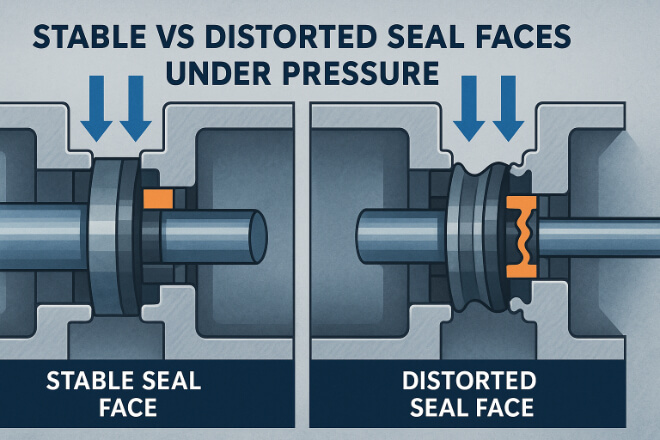

How Modulus and Compressive Strength Influence Carbide Seal Face Stability

Mechanical seals are essential for pumps, compressors, and mixers used in power generation, chemicals, oil & gas, and water treatment. Carbide seal faces are among the most reliable materials for these seals. Two key material properties—elastic modulus and compressive strength—play a major role in seal face stability. Choosing carbide faces without understanding these properties can lead to cracks, leaks, and costly downtime. This article explains modulus and compressive strength in simple terms, shows their impact on seal performance, and helps decision-makers choose the right carbide grade. Why Stability Matters for Carbide Seal Faces Leak prevention: Stable faces keep tight contact under pressure. Reduced wear: Proper stiffness prevents distortion under load. […]

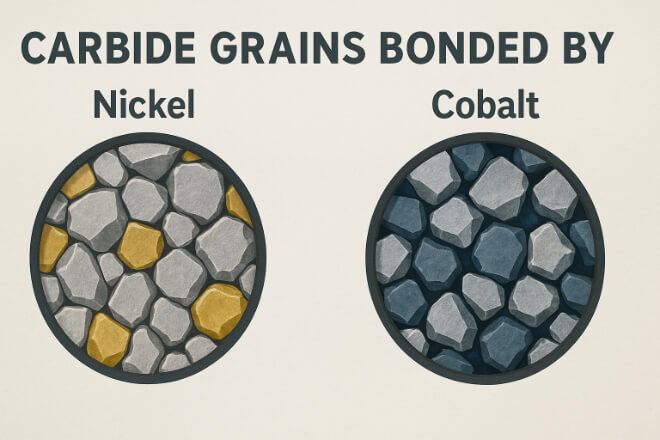

Nickel-Binder vs Cobalt-Binder Carbide Rings for Corrosive Media (Decision Guide)

Handling corrosive liquids or gases is one of the toughest jobs for pumps, compressors, and valves. The seal rings inside this equipment face chemical attack, pressure changes, and constant friction. Two popular choices—nickel-binder carbide rings and cobalt-binder carbide rings—look similar but behave differently under stress. This decision guide compares the two binder types, explaining their unique properties, best use cases, and tips for choosing the right one for corrosive environments. Understanding Binder Materials Tungsten carbide on its own is extremely hard but brittle. A binder metal (nickel or cobalt) is added to improve toughness and bonding between carbide grains. The binder changes how the seal ring reacts to chemicals, temperature […]

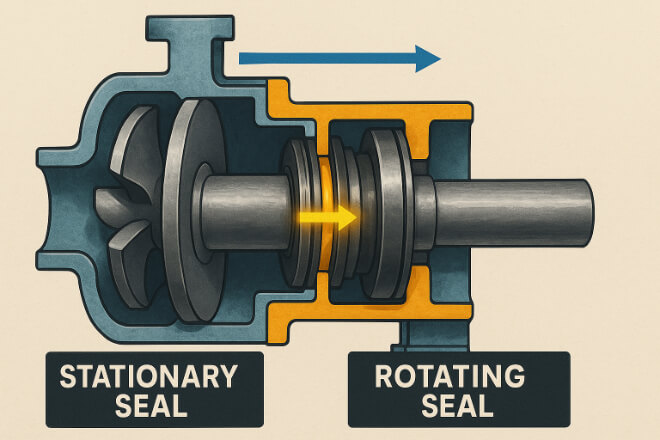

固定式と回転式の超硬シールリング:それぞれの設計を選ぶべきタイミング

In pumps, compressors, and mixers, carbide seal rings are vital for preventing leaks and protecting equipment. The choice between stationary and rotating seal ring designs is critical. Using the wrong type can cause wear, energy loss, and costly downtime. This guide explains the difference between stationary and rotating carbide seal rings, their strengths and weaknesses, and when each design is the better choice. Why Seal Ring Design Matters Leak prevention: Proper selection ensures tight seals under pressure. Equipment protection: Reduces wear on shafts and housings. Energy efficiency: Lower friction reduces power loss. Maintenance savings: Correct design extends service life and reduces repairs. What Are Stationary Carbide Seal Rings? Stationary seal […]