シーリングリングの表面形状:Ra 0.04~0.05 μmが実際に意味するもの

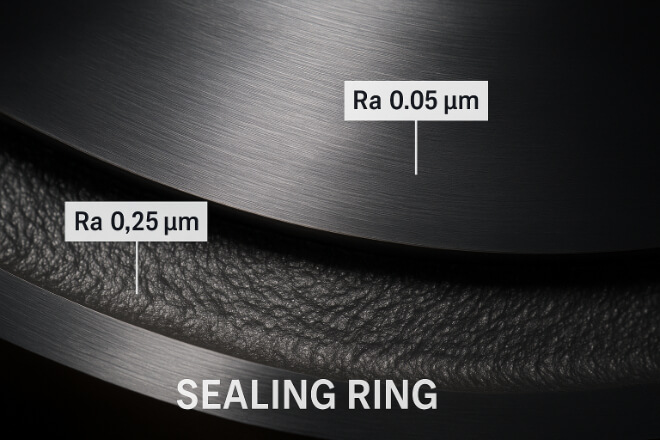

In mechanical seals, the surface topography of sealing rings directly affects leakage control, lubrication retention, and wear resistance. An Ra value between 0.04–0.05 μm is often specified for high-performance applications, but many decision-makers may wonder what this number truly represents and why it matters. This article explains Ra 0.04–0.05 μm in simple terms, its impact on sealing performance, and best practices for achieving and maintaining such surfaces. What Ra 0.04–0.05 μm Represents Ra (Roughness Average) measures the average height of microscopic peaks and valleys on a surface. Ra 0.04–0.05 μm means the surface irregularities are less than one-twentieth of a human hair’s diameter. This level of smoothness is achieved through […]

超硬シールリングの鏡面仕上げの実現:プロセスウィンドウと落とし穴

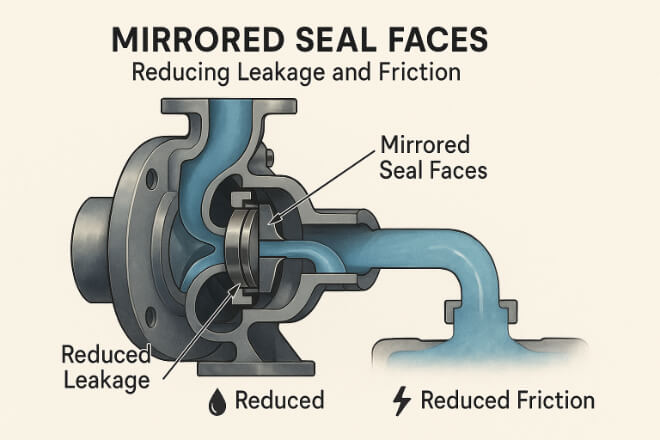

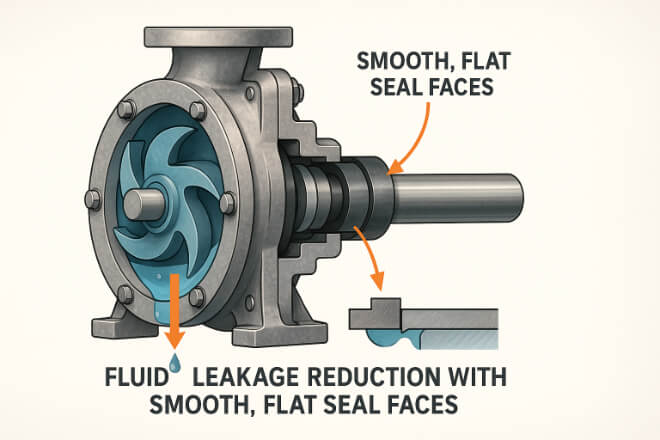

Carbide seal rings are critical components in pumps, compressors, and valves for industries such as oil & gas, chemical processing, power generation, and marine systems. Achieving a mirror-level finish on these rings ensures leakage control, low friction, and long equipment life. However, achieving a perfect mirror finish is not easy. It requires strict process windows, precise lapping and polishing techniques, and an understanding of common pitfalls that can compromise quality. This guide provides decision-makers with practical insights into achieving high-quality finishes on carbide seal rings. Why Mirror-Level Finishes Matter Reduced friction: Smooth faces minimize energy loss. Better sealing performance: Eliminates micro-leakage paths. Wear resistance: Stable surfaces extend component life. Reliability […]

超平滑仕上げとマイクロポケット仕上げ:超硬合金面の潤滑性保持

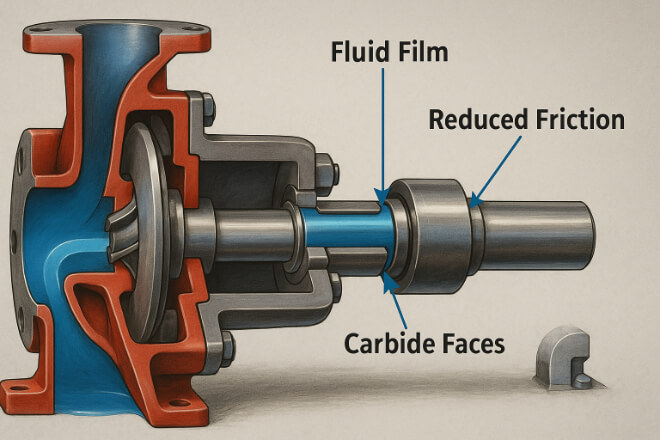

In mechanical seals, the surface finish of carbide faces affects not only leakage control but also lubrication retention. Two popular finishing approaches—ultra-smooth finishes and micro-pocketed finishes—offer different advantages depending on the operating conditions. For decision-makers in industries like oil & gas, chemical processing, marine systems, and power generation, understanding these finishes helps improve seal performance, equipment life, and cost efficiency. Why Lubrication Retention Matters Reduces friction: Adequate lubrication prevents excessive wear. Improves efficiency: Less friction means lower energy consumption. Protects seals: Maintains face integrity under pressure and temperature changes. Prevents dry running: Keeps fluid film stable during startup or low-flow conditions. What Are Ultra-Smooth Finishes? Ultra-smooth finishes are polished surfaces […]

超硬面ラッピング用コンディショニングリング、プレート選択、スラリー制御

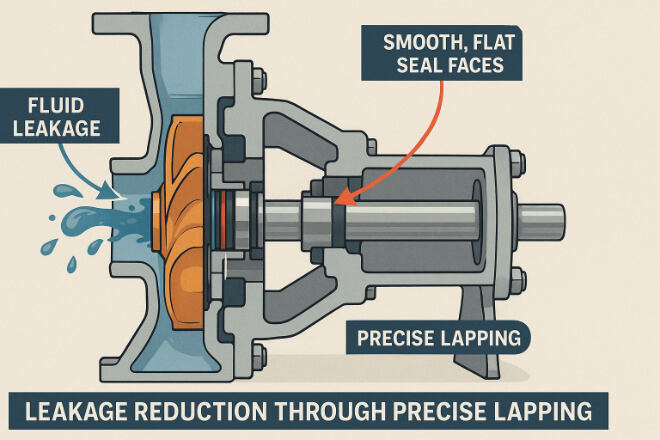

In mechanical seal manufacturing and maintenance, carbide face lapping is a crucial finishing process. Proper lapping ensures surface flatness, low roughness (Ra), and tight sealing performance. Three key factors—conditioning rings, lapping plate selection, and slurry control—determine the quality and repeatability of the finish. This guide explains how these elements affect carbide face lapping and provides best practices for decision-makers aiming to improve seal performance and reduce leakage risks. Why Carbide Face Lapping Quality Matters Leakage control: Flat, smooth faces reduce fluid escape. Seal reliability: Proper lapping prevents premature wear and failures. Energy efficiency: Well-finished faces reduce friction and heat generation. Long-term cost savings: Improved surface quality extends seal life and […]

超硬シール面の目標Raと平坦度:ラッピングと研磨のベストプラクティス

Carbide seal faces are critical for pumps, compressors, and valves in industries like oil & gas, power generation, chemical processing, and water treatment. The surface roughness (Ra) and flatness of these seal faces directly affect leakage control, wear resistance, and equipment reliability. Lapping and polishing are two essential finishing processes that define the final Ra and flatness. Decision-makers must understand the best practices for achieving target values to ensure longer service life, reduced maintenance, and cost savings. Why Ra and Flatness Matter Leakage control: Smooth and flat surfaces create tighter seals. Wear resistance: Proper surface finish reduces friction and prevents premature wear. Energy efficiency: Reduced friction lowers power consumption. Operational […]