From Casting to Mirror Polish: End-to-End Workflow for Carbide Seal Rings

Producing a carbide seal ring that can survive high pressure, abrasive fluids, and corrosive chemicals is not just about material hardness—it’s about precision at every stage of manufacturing. From the casting of tungsten carbide powder to the final mirror-polished surface, each step determines how well the ring seals, resists wear, and maintains flatness in service. This article explains the complete workflow of how carbide seal rings are made—from powder to perfection—highlighting the importance of process control, surface quality. And inspection standards that decision-makers in pump and compressor industries must understand. Powder Preparation: The Foundation of Quality The journey begins with selecting tungsten carbide (WC) powder and a suitable binder metal, […]

Carbide Seal Rings for Semiconductor Wet Benches and Coaters: Cleanliness and Wear

In semiconductor manufacturing, wet benches and coating systems handle some of the world’s purest chemical processes. These tools rely on precise liquid control—using acids, bases, and cleaning solutions—to process wafers with nanometer-level precision. Any contamination, leakage, or wear in the mechanical seal system can cause defects, yield loss, or costly downtime. For this reason, carbide seal rings, particularly tungsten carbide (WC) and silicon carbide (SiC), are widely used in semiconductor wet benches and coaters. They combine exceptional wear resistance, flatness stability, and chemical cleanliness, making them ideal for ultra-pure, high-throughput environments. This article explains why carbide seal rings excel in semiconductor wet benches and coaters, comparing them to other materials […]

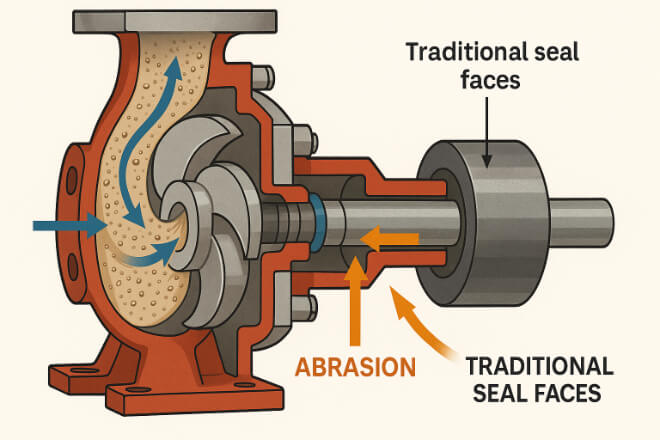

Submersible Pump Seal Stacks: Why Carbide Faces Excel in Sand-Laden Water

Submersible pumps often operate in extremely harsh water environments—such as wells, mines, construction sites, or irrigation systems—where sand, silt, and suspended particles are unavoidable. These fine abrasives quickly damage traditional seal materials, leading to leakage, vibration, and premature failure. To combat this, engineers increasingly rely on carbide seal faces, which are designed to resist abrasion and maintain sealing performance even in sand-laden or dirty water. This article explains why carbide faces outperform other materials in submersible pump seal stacks. How they handle abrasion and pressure, and what design factors decision-makers should consider when specifying seals for demanding applications. The Challenge of Sand-Laden Water Sand is one of the most aggressive […]

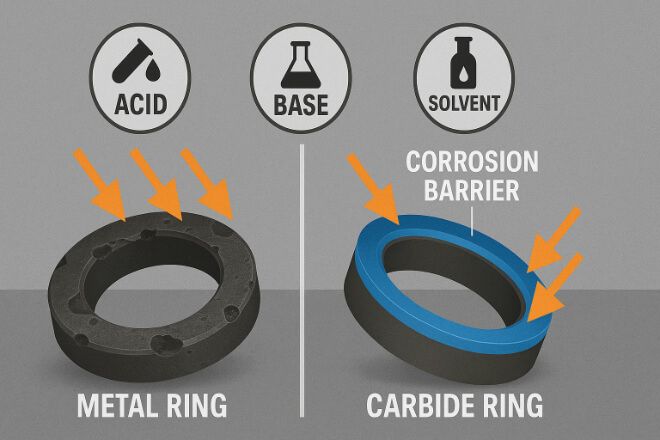

Carbide Seal Rings in Harsh Chemical Media vs Ceramic Rings: Selection Matrix

Selecting the right seal ring material for chemical processing, pharmaceutical, or industrial fluid systems is never simple. In harsh chemical media, the choice often narrows to carbide seal rings or ceramic rings. Both materials offer corrosion resistance and dimensional stability, yet their behaviors under stress, temperature, and chemical exposure differ significantly. For decision-makers managing pumps, compressors, or agitators in corrosive environments, this guide compares carbide. And ceramic seal rings across critical parameters such as chemical resistance, mechanical strength, and tribological performance, supported by a clear selection matrix for practical reference. Understanding Harsh Chemical Media “Harsh chemical media” refers to liquids containing acids, bases, oxidizers, or solvents that can degrade conventional […]

Silicon Carbide vs Tungsten Carbide for Abrasive Slurries: Tribology and Heat Transfer

In pumps, mixers, and valves that handle abrasive slurries, the choice of seal face material is critical. Two of the most used materials are silicon carbide (SiC) and tungsten carbide (WC). Each has unique tribological (friction and wear) and thermal (heat transfer) properties that directly affect reliability, leakage control, and maintenance costs. This article helps decision-makers understand the performance differences between silicon carbide and tungsten carbide when exposed to abrasive, particle-laden fluids, and how these differences impact seal life and overall system efficiency. Tribology Basics: Friction, Wear, and Lubrication Tribology is the science of friction, wear, and lubrication. In a mechanical seal, the two faces—one rotating, one stationary—must remain close […]