How Tungsten Carbide Bushings Improve Machine Performance

In modern industry, machines are expected to run faster, longer, and under more demanding conditions than ever before. Reliability and uptime directly affect productivity and profitability. One small but essential component that makes this possible is the tungsten carbide bushing. These precision-made rings or sleeves are used to support shafts, reduce friction, and protect more expensive machine parts from wear. In this article, we’ll explain how tungsten carbide bushings help improve machine performance, efficiency, and lifespan. We’ll also look at why their unique material properties make them superior to conventional metals or plastics in high-duty applications. What Is a Tungsten Carbide Bushing? A tungsten carbide bushing is a cylindrical component […]

Understanding Hardness and Toughness in Tungsten Carbide Bushings

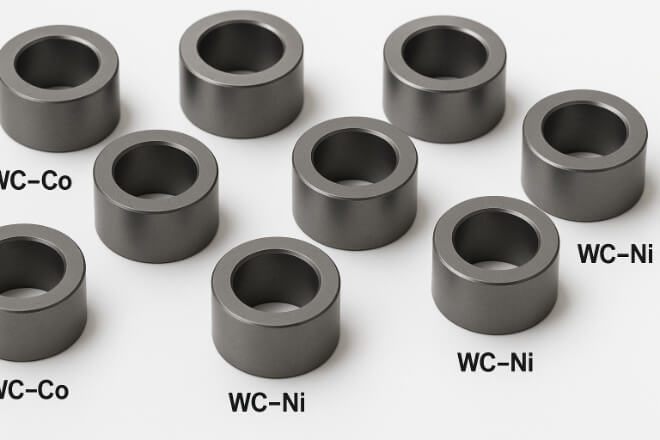

When it comes to mechanical parts that face constant wear, pressure, and friction, tungsten carbide bushings are among the most trusted materials. They are used in pumps, compressors, turbines, and other high-load systems where failure is not an option. Their outstanding durability comes mainly from two material properties — hardness and toughness. Both are vital, but they behave differently and often pull in opposite directions. This article helps you understand what hardness and toughness mean, how they influence the performance of tungsten carbide bushings, and how the right balance leads to long-lasting reliability in harsh industrial conditions. What Is Hardness? Hardness measures how well a material resists deformation, scratching, or […]

The Manufacturing Process of Tungsten Carbide Bushings Explained

Tungsten carbide bushings are small components with a big impact. They provide wear resistance, strength, and reliability in high-pressure and high-friction systems such as pumps, compressors, and turbines. Behind every finished bushing is a complex manufacturing process that turns fine tungsten and metal powders into a precision-engineered part. Each step — from powder preparation to final polishing — determines how long the bushing will last in service. In this article, we’ll explain the complete manufacturing process of tungsten carbide bushings in simple terms, highlight why each step matters, and show how strict process control ensures durability and precision. Raw Material Selection The process begins with choosing the right tungsten carbide […]

Key Properties That Make Tungsten Carbide Bushings Durable

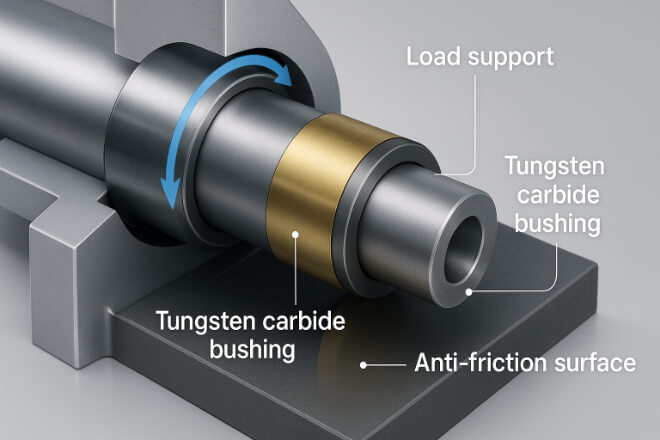

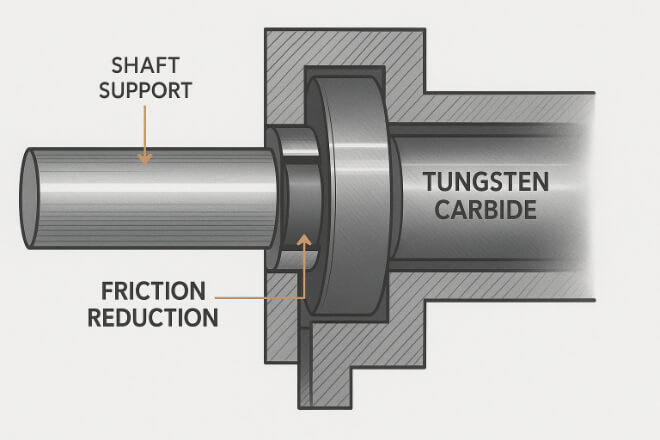

In many industrial machines, small components decide the reliability of the whole system. Bushings, also known as bearing sleeves, play a quiet but essential role — they reduce friction and protect shafts from wear. When equipment runs under high load, abrasive media, or corrosive fluids, ordinary steel or bronze bushings cannot last long. This is where tungsten carbide bushings stand out. These components are designed for maximum wear resistance and long service life, even in the harshest operating environments. This article explains the key material properties that make tungsten carbide bushings so durable and why they are the preferred choice for industries that demand precision, uptime, and cost efficiency. Understanding […]

What Are Tungsten Carbide Bushings and How Do They Work?

In modern machinery, reliability often depends on the smallest components. Bushings, also called bearing sleeves or liners, are one such part. They reduce friction between moving parts and protect shafts or housings from wear. When high loads, abrasive fluids, or extreme temperatures are involved, standard steel bushings wear out quickly. That’s where tungsten carbide bushings come in. These bushings are made from one of the hardest engineering materials available — tungsten carbide (WC) — which provides exceptional wear resistance, hardness, and corrosion protection. This article explains what tungsten carbide bushings are, how they work, where they are used, and why they are a smart investment for demanding industries. What Is […]