What Determines the Quality of Tungsten Carbide Bushings?

In modern industrial machinery, every small part affects the performance of the entire system. Among these parts, tungsten carbide bushings play a key role in reducing friction, supporting rotating shafts, and extending the life of pumps, compressors, and turbines. However, not all carbide bushings are made equal. The quality of a tungsten carbide bushing depends on several factors — from the purity of its raw materials to the precision of its grinding and finishing. Poor-quality bushings may wear quickly, cause vibration, or lead to unplanned equipment downtime. This article explains the major factors that determine the quality, performance, and reliability of tungsten carbide bushings and what decision-makers should look for […]

How Tungsten Carbide Bushings Reduce Equipment Downtime

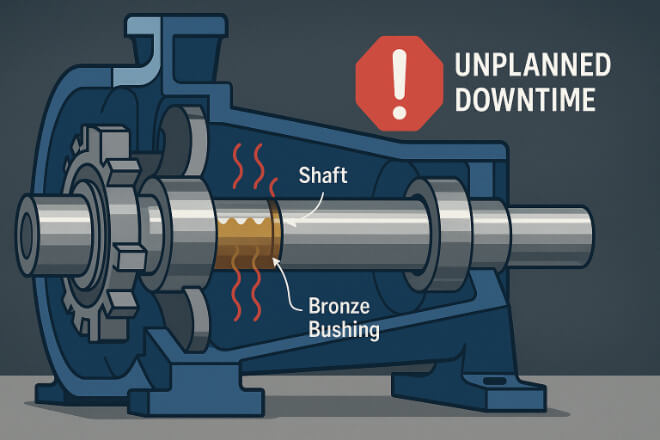

In industrial environments, downtime is expensive. Every hour a pump, compressor, or turbine stops working costs time, money, and sometimes even production losses. Many of these failures start with small components — like bushings — wearing out faster than expected. Tungsten carbide bushings have become the industry standard for reducing maintenance frequency and unplanned shutdowns. Their exceptional hardness, wear resistance, and stability make them ideal for extending equipment life and minimizing downtime. This article explains how tungsten carbide bushings help companies achieve better reliability, lower maintenance costs, and higher operational efficiency. Why Downtime Happens in Rotating Equipment Downtime often begins with minor mechanical failures. Bushings are key elements that guide […]

炭化タングステンが高圧ブッシングに最適な理由

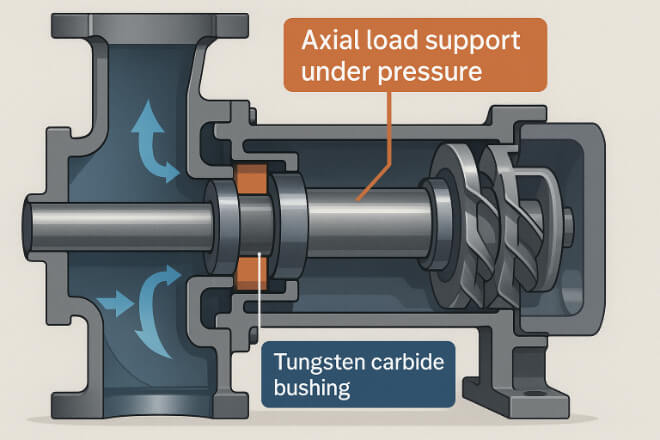

In high-pressure machinery such as pumps, compressors, and hydraulic systems, every part must withstand extreme stress, friction, and temperature. Among all wear-resistant components, tungsten carbide bushings stand out as one of the most reliable materials for these demanding environments. The key lies in the science of strength. Tungsten carbide combines hardness, compressive strength, and thermal stability that allow it to perform where other materials fail. This article explains why tungsten carbide is ideal for high-pressure bushings, examining its structure, performance characteristics, and practical industrial benefits. What Are High-Pressure Bushings? Bushings act as bearings or sleeves that support rotating shafts and reduce friction. In high-pressure systems, they must also resist: Axial […]

The Science Behind Wear Resistance in Tungsten Carbide Bushings

In modern industrial machines, parts are often exposed to friction, pressure, and harsh materials that cause wear. Once wear begins, efficiency drops, clearances increase, and failures become more frequent. To prevent this, engineers use materials that can withstand these demanding conditions — one of the most successful being tungsten carbide. Among its many uses, tungsten carbide bushings are essential in pumps, turbines, compressors, and other rotating systems. Their outstanding wear resistance comes from a combination of material hardness, structure, and microchemical design. This article explains the science behind this wear resistance — how tungsten carbide’s internal structure, bonding, and surface properties work together to deliver exceptional durability. What Causes Wear […]

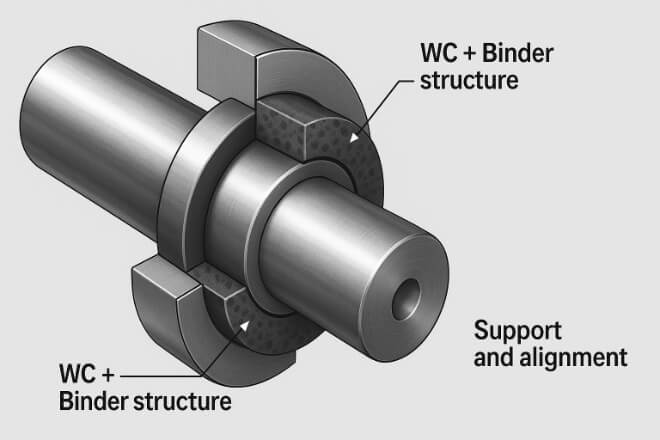

Tungsten Carbide Bushings: Structure, Composition, and Micrograin Types

In modern industrial equipment, precision and reliability depend heavily on materials that can handle extreme wear, pressure, and temperature. One such material is tungsten carbide, and one of its most important applications is in bushings. Tungsten carbide bushings play a key role in supporting rotating shafts, reducing friction, and extending the life of pumps, compressors, turbines, and other machines. Their secret lies in their unique structure, composition, and micrograin design — each engineered for specific performance goals. This article breaks down how tungsten carbide bushings are structured, what they’re made of, and how micrograin size affects their hardness, toughness, and service life. What Is a Tungsten Carbide Bushing? A tungsten […]