高温産業用タングステンカーバイドブッシング

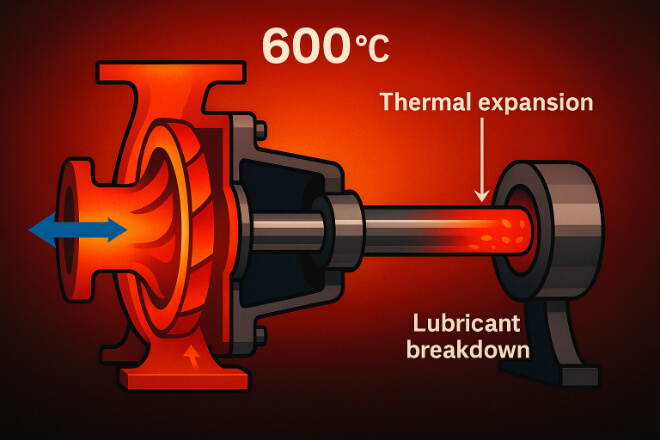

In high-temperature industrial operations, equipment faces extreme thermal stress, friction, and wear. Pumps, compressors, and rotating machinery often run at elevated temperatures for long periods, and even small material weaknesses can lead to failure. Tungsten carbide bushings are one of the few components that can perform reliably under such conditions. They provide excellent thermal stability, hardness, and wear resistance, making them essential in hot environments like power plants, chemical reactors, and metallurgical systems. This article explains how tungsten carbide bushings function in high-temperature operations, their advantages compared to other materials, and best practices for selection and maintenance. Challenges of High-Temperature Operations High-temperature environments are among the most demanding conditions for […]

Using Tungsten Carbide Bushings in Marine and Offshore Environments

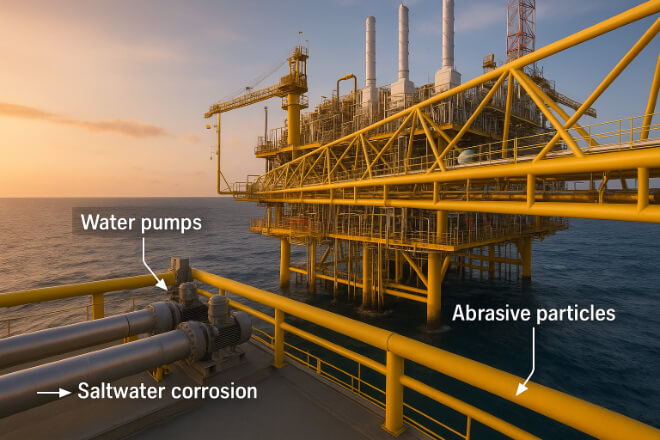

Marine and offshore industries face some of the harshest working conditions on earth. Saltwater, pressure, vibration, and constant exposure to abrasive particles create extreme stress on machinery components. Pumps, compressors, and rotating equipment must operate continuously with little room for error. In such environments, tungsten carbide bushings play a vital role. They provide dimensional stability, wear resistance, and corrosion protection where traditional metals like bronze or stainless steel often fail. This article explains why tungsten carbide bushings are essential for marine and offshore use, how they handle corrosion and wear, and the design factors that make them a long-term investment in reliability. Environmental Challenges in Marine and Offshore Systems Saltwater […]

Tungsten Carbide Bushings in Water Pumps: Corrosion and Erosion Solutions

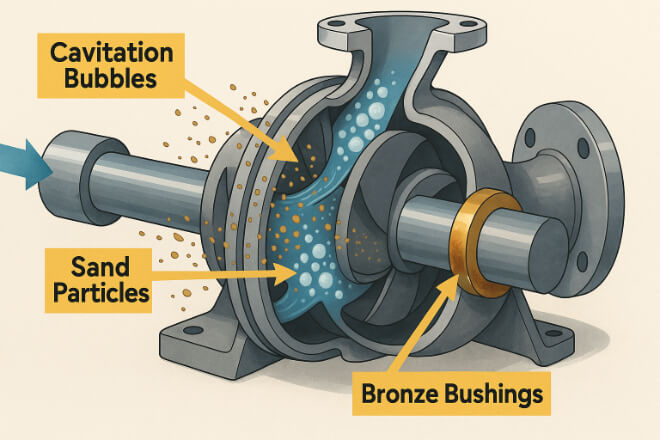

Water pumps are the backbone of modern industry and infrastructure — from power plants and desalination systems to irrigation and wastewater facilities. Yet, many pump failures begin with one small but important part: the bushing. Bushings support rotating shafts, maintain alignment, and reduce friction. However, in water and slurry environments, they are constantly attacked by corrosion and erosion, leading to wear, vibration, and leakage. That’s why tungsten carbide bushings have become a preferred choice. With their high hardness, strength, and corrosion resistance, they provide a durable solution to extend pump life and reduce maintenance. This article explains how tungsten carbide bushings solve corrosion and erosion challenges in water pumps, the […]

Why Tungsten Carbide Bushings Are Essential for Oil and Gas Equipment

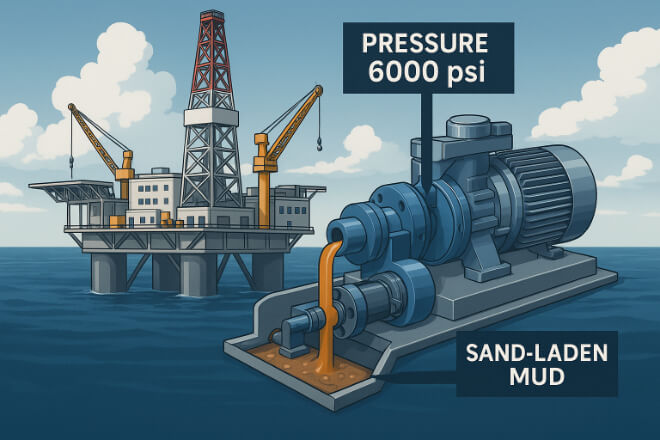

The oil and gas industry operates in one of the toughest environments on Earth. Equipment used in drilling, pumping, and refining faces high pressure, abrasive fluids, extreme temperatures, and corrosive chemicals. To keep systems running safely and efficiently, every component must deliver exceptional reliability. Among these components, tungsten carbide bushings play a vital role. They support rotating shafts, minimize friction, and protect critical equipment such as mud pumps, compressors, turbines, and subsea systems. This article explains why tungsten carbide bushings are essential for oil and gas applications, how they improve reliability, and what makes them superior to conventional materials. The Harsh Operating Conditions in Oil and Gas Oil and gas […]

Applications of Tungsten Carbide Bushings in Pumps and Compressors

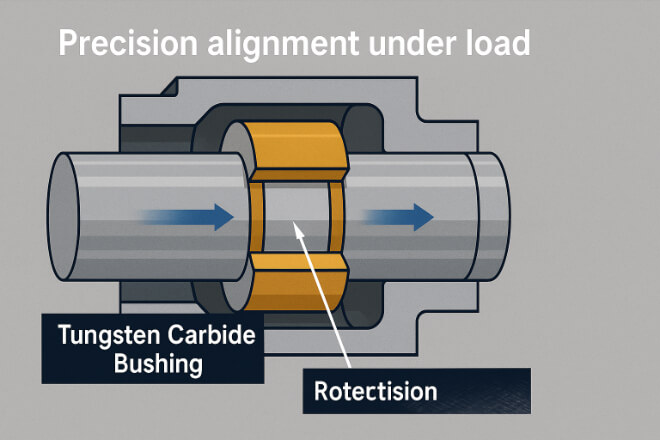

In many industries — from oil and gas to power generation and water treatment — pumps and compressors work non-stop under harsh conditions. Inside these machines, bushings play a small but critical role: they support rotating shafts, reduce friction, and maintain alignment. Among all materials used for bushings, tungsten carbide stands out for its exceptional wear resistance, hardness, and dimensional stability. Its unique combination of mechanical and chemical properties allows pumps and compressors to run longer, with fewer breakdowns and lower maintenance costs. This article explores the key applications of tungsten carbide bushings in pumps and compressors, explaining why this material is preferred for high-performance, high-reliability machinery. Why Tungsten Carbide […]