How to Achieve Precision Fit Between Shaft and Tungsten Carbide Bushing

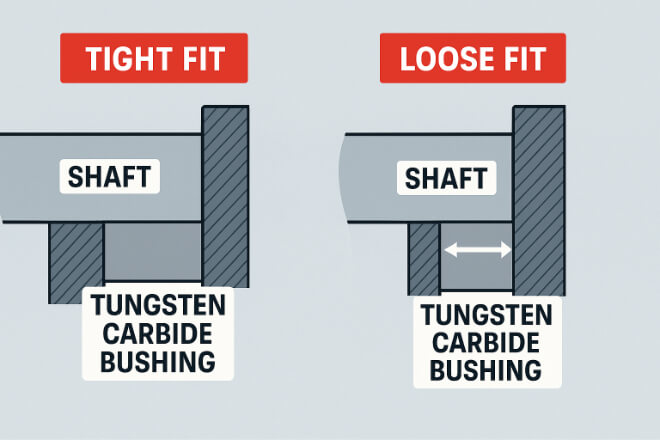

In high-performance machinery, the fit between the shaft and the tungsten carbide bushing determines how efficiently and reliably the system operates. A precision fit ensures correct alignment, minimizes friction, prevents vibration, and extends the lifespan of both the shaft and the bushing. Even if the bushing is made from high-quality tungsten carbide, poor fitting can lead to overheating, wear, or seizure. This article explains how to achieve the correct fit, what factors affect it, and how to measure and maintain precision for long-term performance. Understanding the Importance of Fit The term fit refers to the relationship between the shaft diameter and the bushing bore diameter. A good fit ensures smooth […]

Understanding Tolerances and Surface Finishes in Tungsten Carbide Bushings

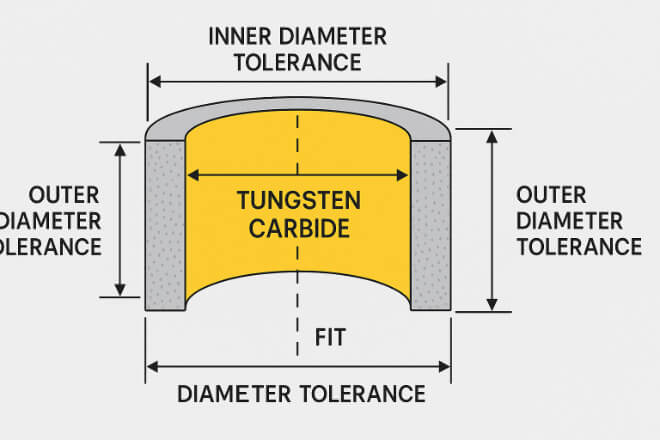

Tungsten carbide bushings are critical components in rotating machinery. They support shafts, control alignment, and minimize wear under high-pressure or high-speed conditions. While most engineers focus on material hardness and composition, tolerances and surface finishes often determine whether a bushing will succeed or fail in real operation. Small differences in dimensional accuracy or roughness can change how fluids flow, how heat is transferred, and how long the equipment lasts. This article explains why tolerances and surface finishes matter, how they are measured, and how to specify the right levels for your tungsten carbide bushings. What Tolerance Means in Tungsten Carbide Bushings In machining, tolerance refers to how much variation is […]

How to Prevent Corrosion and Pitting in Tungsten Carbide Bushings

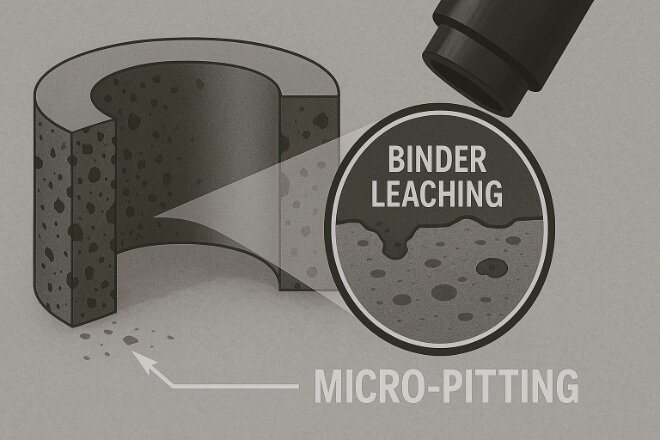

Tungsten carbide bushings are known for their hardness and wear resistance, making them vital in pumps, compressors, and high-load rotating systems. However, corrosion and pitting remain two major threats that reduce service life — especially in chemical, marine, or wet process environments. If corrosion is left unchecked, the binder phase (nickel or cobalt) begins to dissolve, leading to loss of strength, surface roughness increase, and micro-pitting. Understanding the causes and applying proper prevention techniques helps ensure your tungsten carbide bushings deliver maximum durability and performance. Why Corrosion and Pitting Occur Even though tungsten carbide is extremely hard, it is not fully immune to chemical attack. The metallic binder phase is […]

Maintenance Tips to Extend the Life of Tungsten Carbide Bushings

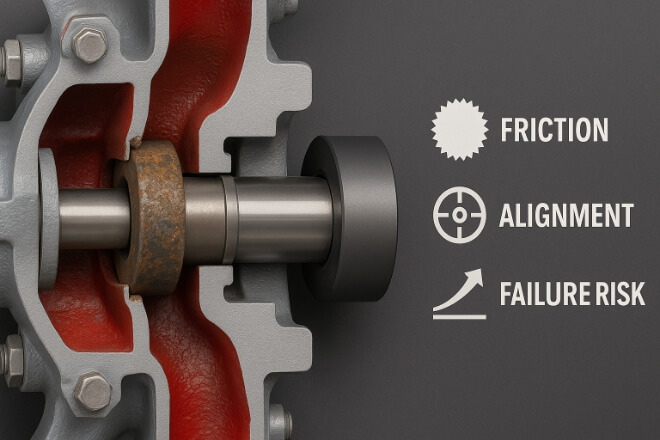

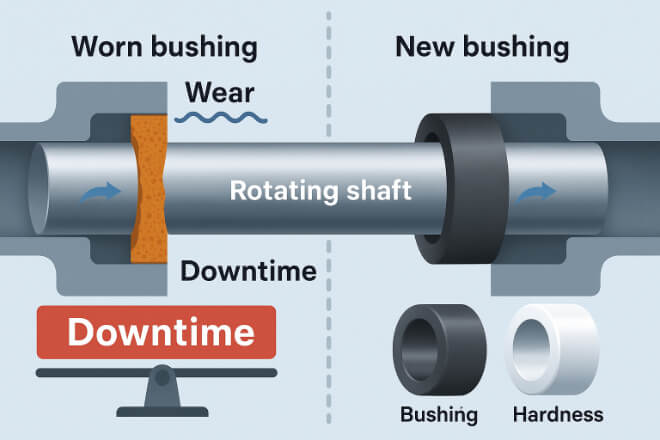

Tungsten carbide bushings are among the most durable components used in pumps, compressors, turbines, and industrial machinery. Their hardness and wear resistance make them ideal for demanding environments. However, even the toughest materials need proper maintenance to deliver long-term performance. Regular inspection, correct lubrication, and suitable operating conditions can significantly extend the lifespan of tungsten carbide bushings — reducing equipment downtime and saving costs. This article provides practical maintenance tips, explains common failure causes, and outlines a preventive maintenance plan to help you get the most out of your tungsten carbide bushings. Why Maintenance Matters Even though tungsten carbide is extremely hard, it is also brittle. Improper handling, contamination, or […]

How to Inspect Tungsten Carbide Bushings for Wear or Damage

Tungsten carbide bushings are known for their exceptional hardness and wear resistance, but even the strongest materials can deteriorate over time. Regular inspection helps detect early signs of wear, cracking, or corrosion before they cause system failures. If inspection is ignored, bushings may seize, increase vibration, or damage shafts — all of which lead to costly downtime. This article explains how to inspect tungsten carbide bushings step by step, what tools to use, and how to determine if replacement is needed. Why Inspection Matters Bushings play a critical role in maintaining shaft alignment, reducing friction, and absorbing load. When wear or cracks go unnoticed, it can cause: Shaft misalignment and […]