カスタムと標準のタングステン カーバイド ブッシング: どちらが適していますか?

When choosing tungsten carbide bushings for industrial equipment, one of the first questions buyers face is: Should I go with standard bushings or custom ones? At first, it may seem easier to pick a standard size — after all, it’s faster and cheaper. But in many high-performance machines, custom tungsten carbide bushings offer better fit, longer lifespan, and lower total cost over time. For decision-makers in industries such as oil & gas, chemical processing, marine, and power generation, understanding the trade-offs between standard and custom bushings helps balance cost, reliability, and long-term performance. This guide explains how both options differ, when to choose each, and what to consider before ordering. […]

グローバル調達ガイド:トップクラスの炭化タングステンブッシングメーカー

In today’s global manufacturing market, sourcing tungsten carbide bushings is not just about finding a supplier — it’s about finding the right partner. Tungsten carbide bushings are critical components in pumps, compressors, turbines, and drilling tools. Their reliability depends heavily on material purity, manufacturing precision, and quality control. As industries become more international, global sourcing allows companies to access better pricing, advanced technology, and specialized expertise. However, choosing the right tungsten carbide bushing manufacturer requires careful evaluation of capability, quality, and certification. This article serves as a comprehensive sourcing guide, helping procurement managers and engineers identify top global manufacturers, key selection factors, and regional strengths. What Makes a Good Tungsten […]

タングステンカーバイドブッシングにおける材料認証の重要性

In modern manufacturing, trust and traceability are everything. When it comes to tungsten carbide bushings, one missing document can mean serious trouble — machine failure, rejected batches, or even safety violations. That document is the material certification. Material certification proves that the bushings you receive were made using verified raw materials that meet required chemical and mechanical standards. It gives assurance that every component — from tungsten powder to binder ratio — is exactly as specified. For companies in oil & gas, chemical, power, and machinery industries, certified carbide bushings are not optional — they are a requirement. This article explains what material certification means, why it matters, and how […]

カスタムタングステンカーバイドブッシングの最小注文数量(MOQ)とリードタイムを理解する

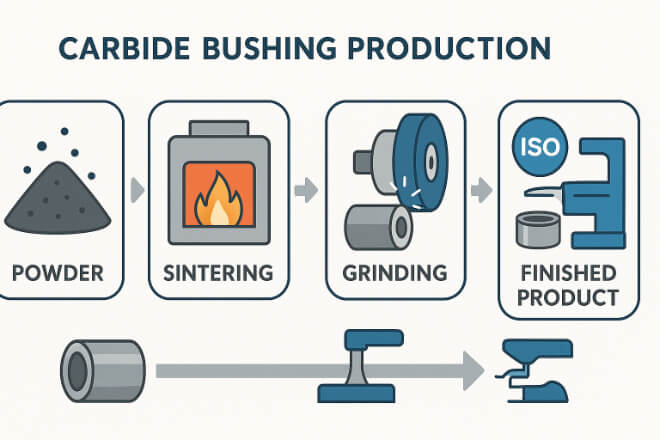

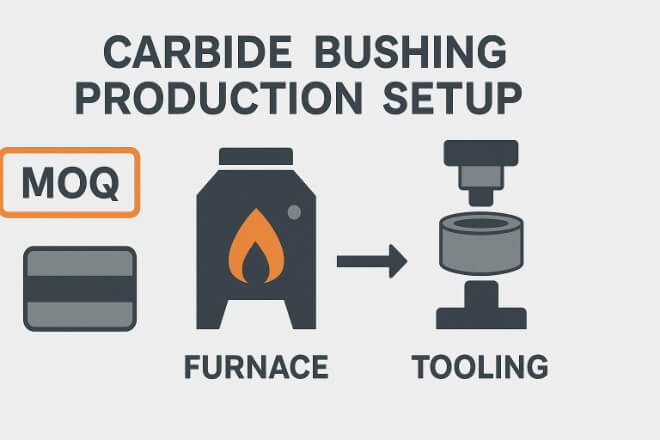

When sourcing custom tungsten carbide bushings, two terms often decide whether your project runs smoothly or faces costly delays: MOQ (Minimum Order Quantity) and lead time. For many decision-makers, these factors directly affect production schedules, procurement costs, and inventory strategies. Understanding how MOQ and lead time are set — and how to manage them effectively — can save both time and money. Tungsten carbide bushings are not standard parts. They are custom-engineered to fit specific shafts, housings, or operational environments. Because of this, each batch requires tailored production, from powder preparation to sintering, grinding, and inspection. This article explains what MOQ and lead time mean in the tungsten carbide manufacturing […]

信頼できるタングステンカーバイドブッシングサプライヤーの選び方

Choosing the right tungsten carbide bushing supplier is one of the most important decisions for any manufacturer or plant operator. The quality of your bushings directly affects machine life, downtime, and maintenance cost. A reliable supplier is not just a vendor — it’s a long-term partner that helps you achieve consistent performance, cost control, and supply stability. This article explains what to look for in a tungsten carbide bushing supplier, how to evaluate their technical and production capabilities, and what signs show a supplier can truly be trusted. Why Supplier Selection Matters Bushings made from tungsten carbide are used in pumps, compressors, turbines, and drilling tools. They operate under extreme […]