Can Tungsten Carbide Bushings Be Recycled?

Tungsten carbide bushings are well-known for their exceptional hardness, wear resistance, and long service life. They are used in critical applications — from pumps and compressors to drilling and automotive systems. But when these bushings reach the end of their service life, what happens next? Can they be reused or recycled? The good news is yes — tungsten carbide bushings can be recycled, and doing so brings both economic and environmental benefits. This article explores how recycling works, why it matters, and how companies can take advantage of tungsten carbide recovery programs. Why Recycling Tungsten Carbide Matters Tungsten carbide is made from tungsten (W) and carbon (C), often bonded with […]

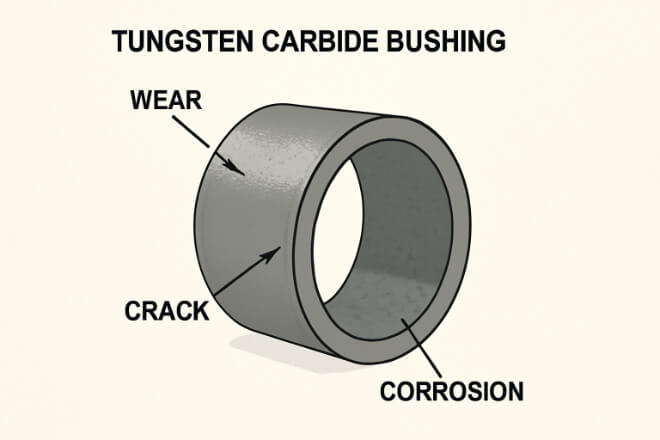

Common Failure Modes in Tungsten Carbide Bushings and How to Avoid Them

Tungsten carbide bushings are used in some of the toughest working conditions — inside pumps, compressors, turbines, and drilling tools. Their main job is to reduce friction and provide stable support for rotating shafts. Although tungsten carbide is extremely hard and durable, it is not indestructible. Improper use, poor lubrication, or incorrect fitting can lead to premature failure. Understanding these failure modes helps engineers and decision-makers extend service life and reduce maintenance costs. This article explains the most common failure types in tungsten carbide bushings, their root causes, and practical ways to avoid them. Why Failure Analysis Matters When a bushing fails, it can damage other expensive components — such […]

Testing and Quality Inspection Methods for Tungsten Carbide Bushings

Tungsten carbide bushings are critical components used in pumps, compressors, and industrial machinery where wear resistance, strength, and precision are essential. For decision-makers in manufacturing or maintenance, ensuring each bushing meets strict quality standards is not optional—it is vital for reliability and cost control. This article explains the main testing and quality inspection methods used for tungsten carbide bushings. It covers mechanical, dimensional, surface, and non-destructive tests in simple terms, helping you understand how reliable suppliers verify product quality before shipment. Importance of Testing and Quality Control Every tungsten carbide bushing must perform under harsh conditions—high pressure, friction, and chemical exposure. Poor-quality bushings can lead to serious failures such as […]

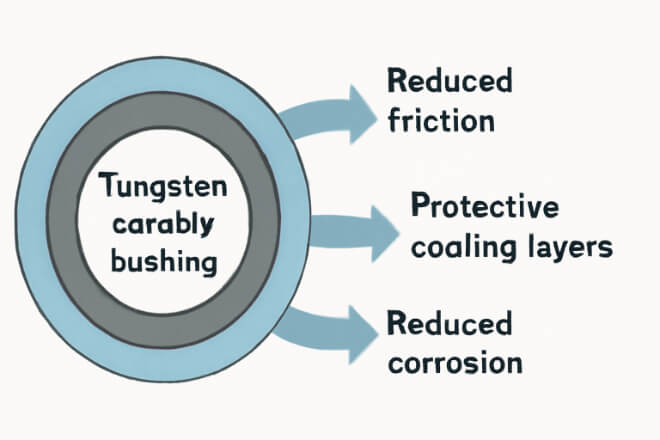

Coatings and Treatments That Enhance Tungsten Carbide Bushing Life

Tungsten carbide bushings are known for their high hardness, wear resistance, and durability. They are used in pumps, compressors, valves, and other heavy-duty machinery where precision and long life are essential. But even the best tungsten carbide will eventually wear out if it faces extreme friction, heat, or corrosion. To extend service life and reduce maintenance, manufacturers apply special coatings and surface treatments. These processes enhance performance by adding extra protection layers against wear, oxidation, and erosion. Understanding which coating or treatment fits your application can save time, cost, and equipment downtime. Why Coatings and Surface Treatments Matter Even though tungsten carbide is one of the hardest engineering materials, it […]

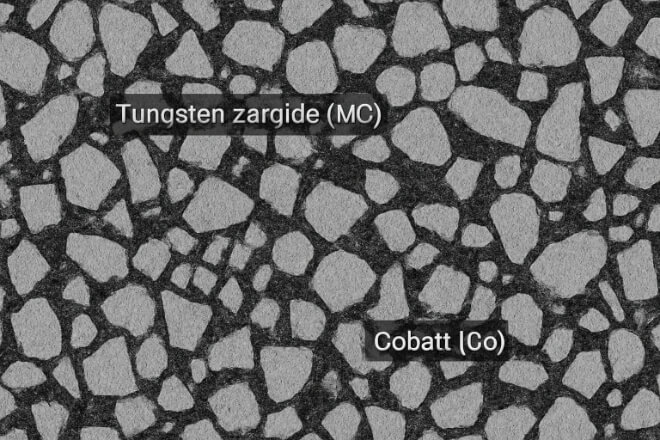

The Role of Grain Size in Tungsten Carbide Bushing Strength

When choosing tungsten carbide bushings, many buyers focus on binder percentage or overall hardness. However, one hidden factor defines how strong, tough, and reliable the part truly is — grain size. The grain size of tungsten carbide controls how the bushing reacts under stress, friction, and temperature. A change as small as a few microns can shift its performance from brittle to durable, or from weak to highly wear-resistant. This article explains how grain size works, how it is controlled during manufacturing, and how it influences the overall strength and service life of tungsten carbide bushings in industrial applications. Understanding Tungsten Carbide Microstructure Tungsten carbide bushings are not made from […]