How Nanostructured Tungsten Carbide Is Changing Bushing Design

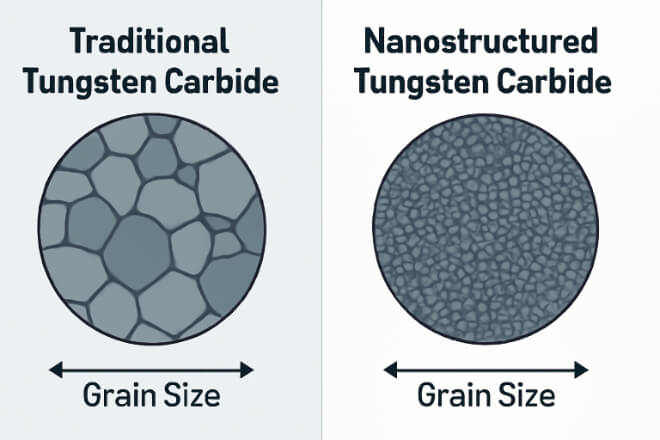

Tungsten carbide bushings are widely used across industries such as mining, oil and gas, aerospace, and automotive for their unmatched wear resistance and durability. However, as demands for higher performance, longer life, and efficiency increase, the need for improved materials becomes ever more pressing. One of the cutting-edge innovations in tungsten carbide technology is nanostructured tungsten carbide. By modifying the structure of tungsten carbide at the nanoscale, manufacturers are creating bushings with superior properties, setting new standards in performance and longevity. What Is Nanostructured Tungsten Carbide? Nanostructured tungsten carbide is a form of tungsten carbide where the grains of the material are refined to the nanoscale level. This means that […]

Latest Innovations in Tungsten Carbide Bushing Materials

Tungsten carbide bushings are a vital component in many industries, offering high wear resistance and durability in demanding environments. However, as technology evolves, so do the materials used to make tungsten carbide bushings. With new innovations, manufacturers can now produce even more efficient, long-lasting, and eco-friendly bushings. In this post, we’ll explore some of the latest advances in tungsten carbide bushing materials that are transforming industries such as mining, oil and gas, automotive, and chemical processing. New Binder Systems for Enhanced Performance Historically, cobalt has been the go-to binder for tungsten carbide due to its strength and toughness. But new binder systems are making waves in improving performance under specific […]

Energy Efficiency Benefits of Long-Life Tungsten Carbide Bushings

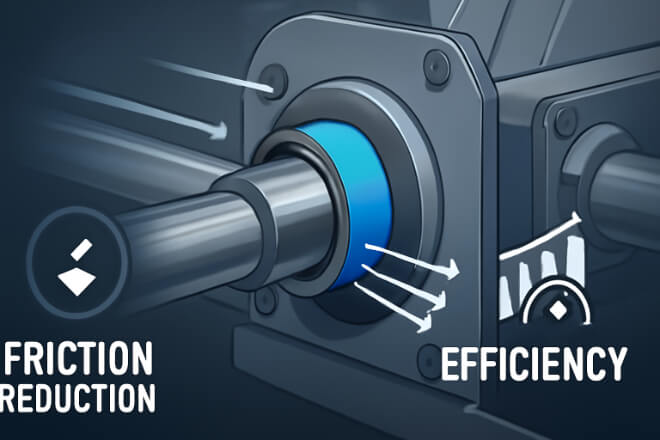

As industries strive to reduce energy costs and minimize environmental impact, tungsten carbide bushings have become a key component in achieving these goals. These high-performance bushings not only enhance the longevity of machinery but also offer significant energy savings. In this blog, we’ll dive into how long-life tungsten carbide bushings can help industries run more efficiently while cutting down on energy consumption. Advantage 1: Reduced Friction for Lower Energy Consumption Tungsten carbide bushings are known for their exceptional hardness and wear resistance, which translates to reduced friction between moving parts. Friction is a major energy drain in machinery, as more energy is required to overcome resistance. Tungsten carbide’s low friction […]

Eco-Friendly Aspects of Using Tungsten Carbide Bushings

In industries worldwide, sustainability is becoming a key focus. As companies search for eco-friendly alternatives, tungsten carbide bushings have gained recognition for their environmental benefits. This article will explore the eco-friendly advantages of using tungsten carbide bushings, focusing on their durability, energy efficiency, recyclability, and low maintenance. Advantage 1: Durability and Longevity Tungsten carbide bushings are known for their exceptional durability. Unlike softer materials, tungsten carbide is highly resistant to wear and tear, meaning the bushings last much longer. For instance, in aerospace and oil and gas industries, components made from tungsten carbide can endure for several years without needing replacements. This reduces the frequency of manufacturing new parts, which […]

How Recycling Tungsten Carbide Bushings Reduces Waste and Cost

Tungsten carbide bushings are essential components used in various industrial applications, particularly in demanding environments like mining, pumps, and automotive systems. These bushings are known for their durability, wear resistance, and ability to handle high-pressure and high-temperature conditions. However, like any industrial material, tungsten carbide eventually wears out and needs to be replaced. The good news is that recycling tungsten carbide bushings offers a powerful solution to reduce both waste and costs. In this article, we will explore how recycling helps minimize environmental impact, reduces the demand for new raw materials, and results in significant cost savings for companies. Why Recycling Tungsten Carbide Bushings Is Important Tungsten carbide is made […]