How Tungsten Carbide Bushings Improve Compressor Reliability

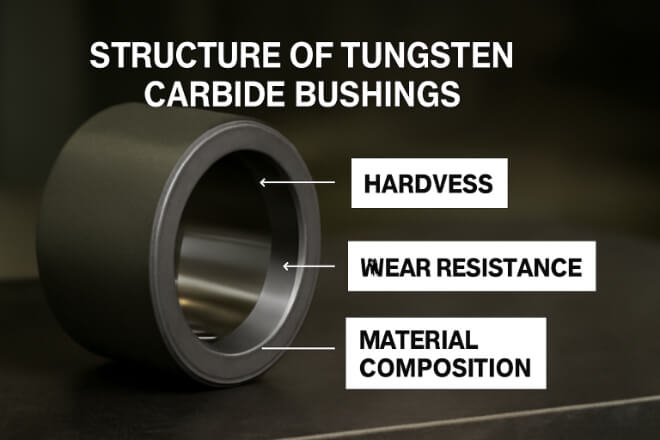

Compressors are essential in many industries, but they are often subject to wear and tear, leading to costly downtime. Tungsten carbide bushings improve compressor reliability by offering superior wear resistance, reducing maintenance, and extending service life. In this article, we’ll explore how these bushings contribute to smoother, more efficient compressor performance. What Are Tungsten Carbide Bushings? Tungsten carbide bushings are components made from a combination of tungsten and carbon, which together form a highly durable material. These bushings are used as bearings to reduce friction between moving parts in compressors, which is essential to maintaining the smooth operation of the system. Tungsten carbide’s exceptional hardness and wear resistance make it […]

Tungsten Carbide Bushings for Centrifugal Pump Shafts

Centrifugal pumps are essential in industries such as water treatment, oil and gas, and chemicals. The pump shaft, which rotates at high speeds, is prone to wear. Tungsten carbide bushings offer an ideal solution for these shafts, providing durability, wear resistance, and performance in harsh conditions. In this article, we will explore why tungsten carbide bushings are the go-to choice for centrifugal pump shafts. What Are Tungsten Carbide Bushings? Tungsten carbide bushings are components made from a combination of tungsten and carbon. Known for their hardness and durability, these bushings are used to reduce friction and wear between moving parts, making them ideal for centrifugal pumps. The material’s strength allows […]

Hybrid Tungsten Carbide Composites for Extreme Conditions

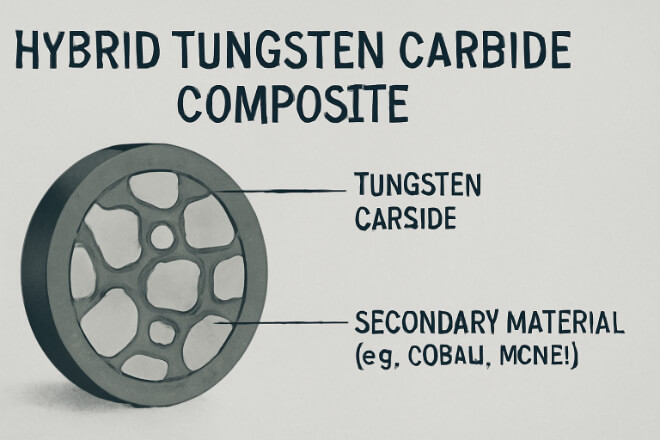

In industries such as mining, oil & gas, and aerospace, machinery is often subjected to extreme conditions—high temperatures, pressures, and abrasive materials. To address these challenges, hybrid tungsten carbide composites are becoming increasingly popular. By combining tungsten carbide with other materials, these composites offer exceptional durability, wear resistance, and toughness. This article will explore the advantages of hybrid tungsten carbide composites for extreme environments and what decision-makers need to know. What Are Hybrid Tungsten Carbide Composites? Hybrid tungsten carbide composites are materials made by combining tungsten carbide (WC) with other materials like cobalt, nickel, or ceramics. The base material, tungsten carbide, is known for its hardness and wear resistance, but […]

Advances in Tungsten Carbide Bushing Coating Technology

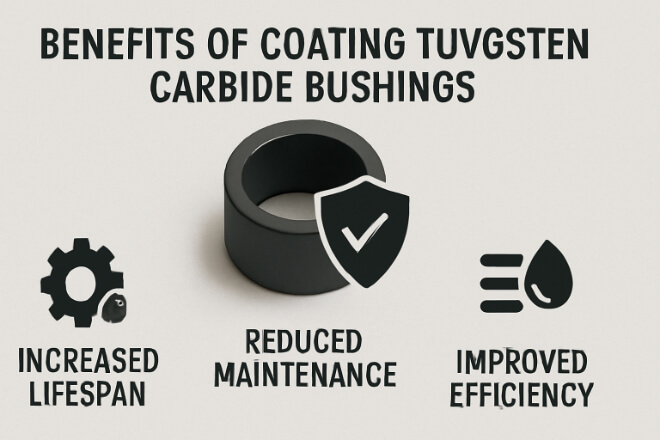

Tungsten carbide bushings are crucial in many industrial applications due to their superior hardness and abrasion resistance. However, even the best materials require additional protection. Advanced coating technologies can significantly improve the performance, service life, and resilience of these bushings under harsh conditions. In this article, we will explore how coatings improve tungsten carbide bushings and the benefits they bring to various industries. The Importance of Coatings for Tungsten Carbide Bushings Tungsten carbide is renowned for its durability, and coatings provide an extra layer of protection, enabling it to withstand abrasion, corrosion, and other challenges. Coated tungsten carbide bushings have a longer service life, reducing the need for maintenance and […]

3D Printing and Tungsten Carbide Bushings: Future of Manufacturing

In recent years, 3D printing has revolutionized many industries, particularly manufacturing. This advanced technology allows for precision, reduced waste, and quicker production timelines. When combined with tungsten carbide bushings, which are essential components in various machinery, the potential for innovation is vast. This article explores how 3D printing is shaping the future of manufacturing, specifically focusing on tungsten carbide bushings. What Are Tungsten Carbide Bushings? Tungsten carbide bushings are components made from a hard and durable material used in various industrial applications. They are crucial in systems requiring wear-resistant parts, such as pumps, compressors, and manufacturing equipment. The material’s exceptional hardness and resistance to corrosion make it ideal for harsh […]