Optimal Surface Finish for Tungsten Carbide Bushings

The surface finish of tungsten carbide bushings plays a crucial role in their performance, longevity, and efficiency in various applications. Achieving the optimal surface finish can reduce wear, lower friction, and improve the overall functioning of the machinery. In this blog, we will explore the importance of surface finish for tungsten carbide bushings, factors that influence it, and how to achieve the best finish for specific industrial needs. What is Surface Finish and Why is it Important for Tungsten Carbide Bushings? Surface finish refers to the texture of a surface that has been machined or treated. For tungsten carbide bushings, it is the final quality of the surface that interacts […]

Clearance Fit Guidelines for Tungsten Carbide Bushings

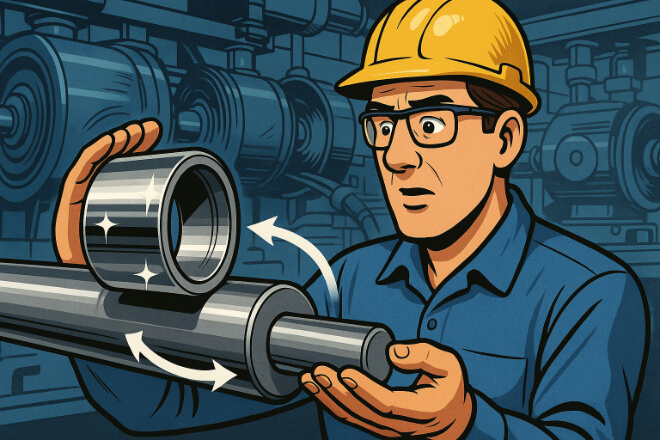

Selecting the right clearance fit for tungsten carbide bushings is critical for ensuring the efficiency and longevity of machinery. The proper fit ensures smooth operation, reduces friction, and minimizes wear. This blog will guide you through the key considerations when choosing the appropriate clearance fit for tungsten carbide bushings. Its impact on performance, and how to optimize it for your specific applications. What is Clearance Fit and Why is it Important for Tungsten Carbide Bushings? Clearance fit refers to the amount of space between two components, such as a shaft and a bushing, allowing them to move freely without causing interference. In the case of tungsten carbide bushings, the correct […]

Tungsten Carbide Bushings for High-Temperature Environments

Tungsten carbide bushings are well-known for their exceptional durability and wear resistance. In high-temperature environments, where many materials fail to perform reliably, tungsten carbide stands out as a preferred material. This blog will discuss why tungsten carbide bushings are an excellent choice for applications exposed to high heat. The factors to consider when selecting them, and the benefits they provide to industries like aerospace, automotive, and chemical processing. Why Tungsten Carbide is Ideal for High-Temperature Applications Tungsten carbide is widely used in industries where high temperatures and wear-resistant components are crucial. This is because tungsten carbide has a unique combination of properties that make it capable of withstanding extreme conditions: […]

How to Select Tungsten Carbide Bushings for Deepwell Pumps

Selecting the right tungsten carbide bushings for deepwell pumps is critical to ensuring the long-term reliability and efficiency of your pumping systems. Tungsten carbide offers outstanding wear resistance and toughness, making it an ideal material for high-stress environments like deepwell pumps. This guide will walk you through the key factors to consider when choosing tungsten carbide bushings for these demanding applications. Understand the Role of Tungsten Carbide Bushings in Deepwell Pumps Tungsten carbide bushings are used in deepwell pumps to support the moving parts, reduce friction, and ensure smooth operation under extreme conditions. These bushings help prevent wear and tear caused by the high-pressure environment of deepwell operations. By reducing […]

Tungsten Carbide Bushings for Aggressive Fluids and Corrosive Media

Tungsten carbide bushings are essential for industries that work with aggressive fluids and corrosive media. These bushings are highly valued for their wear resistance, corrosion resistance, and thermal stability, making them ideal for applications in chemical processing, oil and gas, and mining. Why Tungsten Carbide Bushings Excel in Harsh Environments 1). Superior Corrosion Resistance Tungsten carbide is known for its outstanding corrosion resistance. In industries where machinery is exposed to corrosive substances such as acids, salts, and alkalines, tungsten carbide offers reliable protection against chemical degradation. This property makes it an excellent choice for pumps, valves, and agitators that regularly handle corrosive media, reducing the need for frequent replacements and […]