Common Installation Mistakes with Tungsten Carbide Bushings

Tungsten carbide bushings are highly valued for their exceptional wear resistance, toughness, and longevity. However, improper installation can lead to premature failure or reduced performance, even in these durable components. In this blog, we will explore the most common installation mistakes made with tungsten carbide bushings and offer practical solutions to avoid these pitfalls. By following best practices during installation, you can maximize the lifespan and performance of your tungsten carbide bushings. Error 1: Failing to Properly Align the Bushing One of the most common mistakes during the installation of tungsten carbide bushings is improper alignment. Misalignment can cause uneven stress, leading to increased wear, premature failure, or even cracking […]

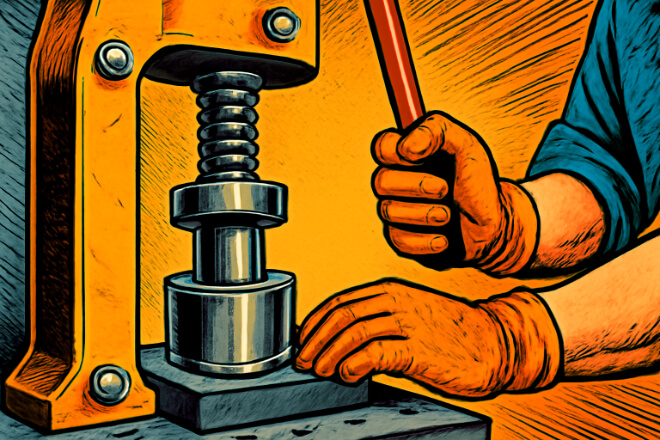

How to Press-Fit Tungsten Carbide Bushings Without Cracking

Tungsten carbide bushings are widely used in industries that require exceptional wear resistance, durability, and toughness. These bushings play a critical role in high-performance machinery, from pumps to heavy equipment. However, one common challenge during installation is the risk of cracking the bushing during the press-fit process. This blog will explore how to press-fit tungsten carbide bushings properly, minimizing the risk of cracking and ensuring long-lasting performance. What is Press-Fitting? Press-fitting is a method of installing a component, such as a bushing, into a housing or bore by applying a force that presses the part into place. The fit is typically tight enough to create a frictional bond that holds […]

The Role of Polishing and Lapping in Tungsten Carbide Bushing Performance

Tungsten carbide bushings are highly valued for their durability, wear resistance, and hardness, making them ideal for use in demanding applications like pumps, machinery, and aerospace components. However, to ensure optimal performance and lifespan, the surface finish of the bushings plays a crucial role. Two key processes that significantly impact the performance of tungsten carbide bushings are polishing and lapping. In this blog, we will explore the role of polishing and lapping in enhancing the performance of tungsten carbide bushings, focusing on their effects on friction, wear resistance, and overall efficiency. What is Polishing? Polishing is a process that involves smoothing the surface of a material to a high shine. […]

Common Machining Tolerances for Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in industries that require high durability and resistance to wear, such as automotive, aerospace, and manufacturing. To ensure that these bushings perform optimally, it is crucial to adhere to specific machining tolerances during their manufacturing process. In this blog, we will explore the common machining tolerances for tungsten carbide bushings, how these tolerances affect performance, and the importance of precision in achieving long-lasting results. What are Machining Tolerances? Machining tolerances refer to the allowable deviation from the specified dimensions of a component. In simpler terms, they define how precisely a part must be manufactured to meet its design specifications. Tolerances are essential because even […]

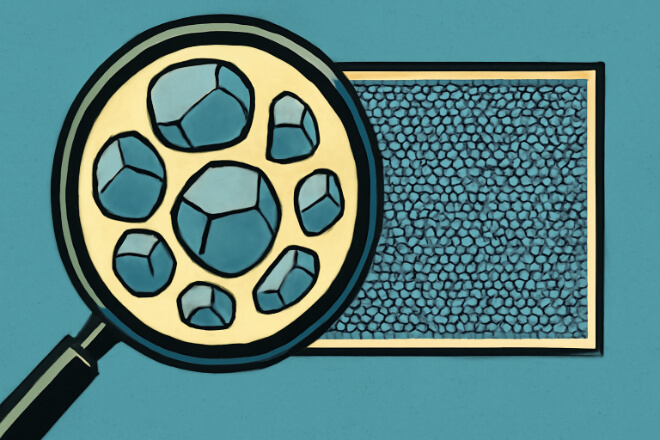

Understanding Micrograin vs Submicron Tungsten Carbide Bushings

Tungsten carbide bushings are essential components in industries that require high wear resistance and durability, such as automotive, mining, and aerospace. One critical factor in the performance of these bushings is the grain size of the tungsten carbide material used to manufacture them. In this blog, we will explore the differences between micrograin and submicron tungsten carbide bushings, the benefits of each, and how to select the right one for your specific application. What is Micrograin Tungsten Carbide? Micrograin tungsten carbide is a material made from tungsten carbide particles that have a relatively larger size compared to submicron tungsten carbide. These grains typically range from 1–5 microns in size. The […]