How to Improve Shaft Alignment for Longer Bushing Life

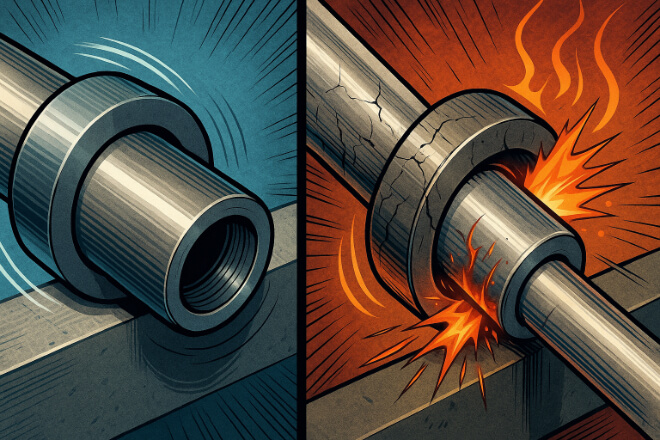

Good shaft alignment is one of the most important factors for achieving long service life in tungsten carbide bushings. When the shaft is not aligned well, the bushing faces extra stress, heat, and wear. This leads to early failure and higher maintenance costs. This article explains how to improve shaft alignment using simple steps, practical tools, and industry best practices. Why Shaft Alignment Matters for Bushing Life Shaft alignment refers to how well the shaft centerline matches the bushing centerline. Even small alignment errors can create big problems during operation. 1). Key Issues Caused by Poor Alignment Higher friction and heat Uneven load on the bushing Faster wear and shorter […]

Noise and Vibration Problems in Tungsten Carbide Bushing Assemblies

Noise and vibration are early warning signs of problems inside equipment that uses tungsten carbide bushings. If these issues are ignored, they can lead to higher wear, reduced efficiency, and unexpected downtime. This article explains why noise and vibration occur, the risks they bring, and how to prevent failures in tungsten carbide bushing systems. Why Noise and Vibration Matter in Bushing Assemblies Noise and vibration usually show that something is not working correctly inside the bushing assembly. Tungsten carbide bushings are meant to run smoothly with low friction. When unusual noise appears, it means friction or movement has increased. Common risks include: Faster wear on bushings and shafts Higher operating […]

Common Reasons for Leakage Around Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in machinery and pumps due to their exceptional hardness, wear resistance, and strength. However, even the most durable materials can face issues in demanding industrial applications. Leakage around tungsten carbide bushings is a common problem that can cause significant operational issues, including reduced efficiency, increased maintenance costs, and potential system failures. Understanding the common reasons for leakage can help prevent such problems and ensure the longevity of your equipment. In this article, we will explore the primary causes of leakage around tungsten carbide bushings and provide best practices to prevent and address these issues. Common Causes of Leakage Around Tungsten Carbide Bushings Leakage around […]

Reducing Friction and Galling with Proper Tungsten Carbide Pairing

Tungsten carbide is renowned for its exceptional hardness, wear resistance, and durability, making it a popular choice for industrial applications such as bushings, bearings, and seals. However, even tungsten carbide can face issues like friction and galling when paired improperly with other materials. These issues can result in excessive wear, damage, and ultimately failure of machinery components. In this article, we’ll explore how proper pairing of tungsten carbide with compatible materials can reduce friction and galling, improve the performance of your machinery, and increase the longevity of your components. What is Galling and How Does It Affect Tungsten Carbide? 1). Understanding Galling Galling is a form of adhesive wear that […]

Temperature Limits for Tungsten Carbide Bushings in Service

Tungsten carbide bushings are known for their outstanding wear resistance and strength, making them ideal for a wide range of industrial applications. However, like all materials, tungsten carbide has temperature limits that must be considered to ensure optimal performance. Understanding these temperature limits is crucial for industries such as mining, oil and gas, and aerospace, where bushings are often subjected to extreme conditions. This article will explore the temperature limits for tungsten carbide bushings, factors that affect their performance at high temperatures, and best practices for maximizing their service life. What is Tungsten Carbide and Why Temperature Matters? Tungsten carbide (WC) is a highly durable material made by combining tungsten […]