Tungsten Carbide Bushing Sourcing Guide for OEMs

For OEMs in the pump, compressor, turbine, and industrial machinery sectors, choosing the right supplier for tungsten carbide bushings is a critical decision. A reliable supplier helps reduce downtime, increase product life, and ensure long-term performance. This guide explains the key sourcing steps every OEM should follow to select the best material grade, evaluate manufacturers, and lock in a stable, high-quality supply chain. Understand Your Technical Requirements First Before contacting any supplier, OEMs must define the operating conditions for the bushing. This ensures the selected tungsten carbide grade and design fit the equipment’s performance needs. 1). Key Requirements OEMs Should Prepare Equipment type (pump, compressor, turbine, mixer) Shaft speed and […]

How to Order Custom Tungsten Carbide Bushings

Ordering custom tungsten carbide bushings can be challenging, especially when the application involves pumps, compressors, turbines, high pressure, or abrasive fluids. To get the right part, you must provide clear technical details and understand the key factors that influence design, performance, and cost. This article guides decision-makers through each step of the ordering process to ensure the custom bushing matches your equipment needs and operating conditions. Know Your Application Requirements Before contacting a supplier, you need to define the operating environment. This helps select the correct carbide grade, binder type, dimensions, and finish. 1). Key Factors to Identify Equipment type (pump, compressor, mixer, turbine, etc.) Rotational speed Load and pressure […]

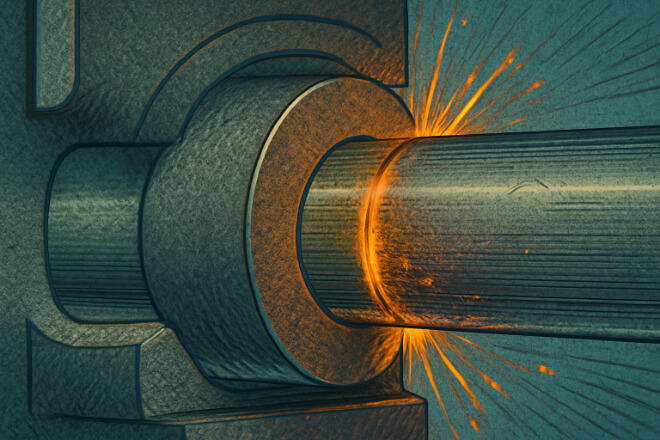

Troubleshooting Bearing Clearance Issues in Tungsten Carbide Bushings

Bearing clearance is one of the most important factors in the performance of tungsten carbide bushings. If the clearance is too tight or too loose, problems such as friction, vibration, heat, noise, or even full pump failure can occur. This article explains the common causes of clearance problems, how to detect them, and the best ways to fix and prevent them in pumps, compressors, and other rotating equipment. Why Correct Clearance Matters Tungsten carbide bushings are used because they provide strength, hardness, and stability under high load. But they can only work correctly when the bearing clearance is within the design range. 1). If clearance is too small Excessive friction […]

Why Some Tungsten Carbide Bushings Fail Prematurely

Tungsten carbide bushings are known for their strength, hardness, and long service life. They are widely used in pumps, compressors, turbines, and other rotating equipment. But in real industrial environments, some bushings fail much earlier than expected. Early failure means unplanned downtime, higher maintenance costs, and possible damage to shafts or seals. This article explains the main reasons behind premature failure and what decision-makers can do to prevent it. Poor Raw Material Quality Not all tungsten carbide bushings are produced with the same material quality. Poor powder quality or incorrect binder ratios can significantly reduce strength and wear resistance. 1). Common Raw Material Problems Low-purity tungsten carbide powder Incorrect cobalt […]

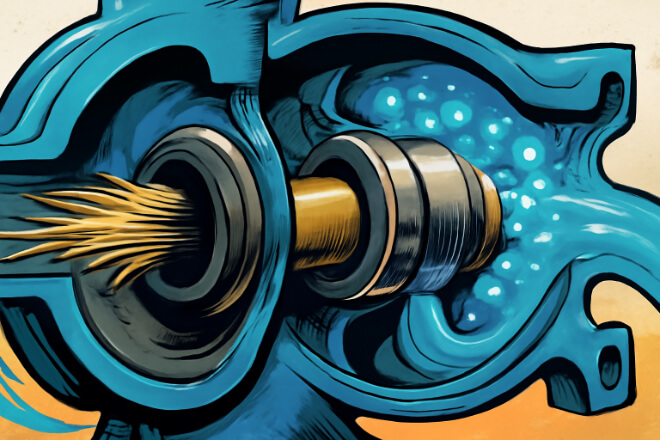

Detecting Erosion and Cavitation Damage in Pump Bushings

Pump bushings made of tungsten carbide work under high speed, high pressure, and aggressive fluids. In these harsh conditions, two common failure modes appear again and again: erosion and cavitation damage. Both can cause early wear, vibration, leakage, and even shutdown of the pump. This article explains how to detect these problems early, why they occur, and what signs decision-makers should watch for to protect their equipment and reduce downtime. Understanding Erosion and Cavitation in Pump Bushings Erosion and cavitation look similar at first glance, but they come from very different causes. Understanding the difference helps engineers choose the right materials, improve operation conditions, and prevent damage before it becomes […]