OEM Replacement Guide for Tungsten Carbide Bushings

Replacing tungsten carbide bushings is a key task for OEMs that run pumps, compressors, motors, or rotating equipment. A correct replacement process ensures stable performance, low downtime, and long service life. This guide explains how OEMs can evaluate old bushings, select the right replacements, and work with suppliers to ensure accuracy and quality. When OEMs Should Consider Replacing Tungsten Carbide Bushings Tungsten carbide bushings are known for high hardness and long life, but they still wear with time. OEMs need to replace bushings before they cause major equipment problems. 1). Common situations that require replacement: Visible wear marks or scratches on the inner or outer surface Loss of roundness, causing […]

Factors That Influence the Export Cost of Tungsten Carbide Bushings

Exporting tungsten carbide bushings in 2025 involves more than material and machining cost. For OEMs and global buyers, the final export price depends on many hidden factors—logistics, regulations, currency, packaging, and regional supply changes. This article explains the key cost drivers in simple, clear language to help decision-makers understand how export prices are built and how to better plan sourcing strategies. Raw Material Cost and Market Fluctuations Raw material cost is the largest part of tungsten carbide bushing pricing. Tungsten ore and carbide powder shift in price based on global supply, mining output, and political conditions. 1). Key points that influence raw material cost Tungsten ore supply: If mining output […]

Global Price Trends of Tungsten Carbide Bushings in 2025

In 2025, the steel-hard compound used for bushings — tungsten carbide — is seeing significant price shifts. For companies sourcing tungsten carbide bushings, understanding global price trends is vital to managing cost, supply risk and contract timing. This article outlines major price movements across regions, key drivers behind change, and what decision-makers should do when negotiating supply contracts. Overview of Global Market Context The broader tungsten carbide market sets the stage for bushing prices. According to market research the global tungsten carbide market size is estimated at around USD 17.54 billion in 2025. Another report shows tungsten carbide powder pricing in Q3 2025: USA ~ USD 50.8/kg, China ~ USD […]

Evaluating Supplier Capability for Tungsten Carbide Bushings

Choosing the right supplier for tungsten carbide bushings is a critical step for OEMs and industrial companies. A strong supplier can help you reduce downtime, improve product performance, and ensure stable long-term supply. This guide explains how to evaluate supplier capability using clear and practical criteria that match real industrial needs. Why Supplier Capability Matters Tungsten carbide bushings work under high load, speed, heat, and abrasive fluids. If the supplier cannot maintain quality, stability, and precision, the equipment will fail early. 1). Good supplier capability results in: Stable and repeatable dimensions High hardness and density Fewer defects like cracks or porosity Better surface finish Lower downtime in your equipment Reliable […]

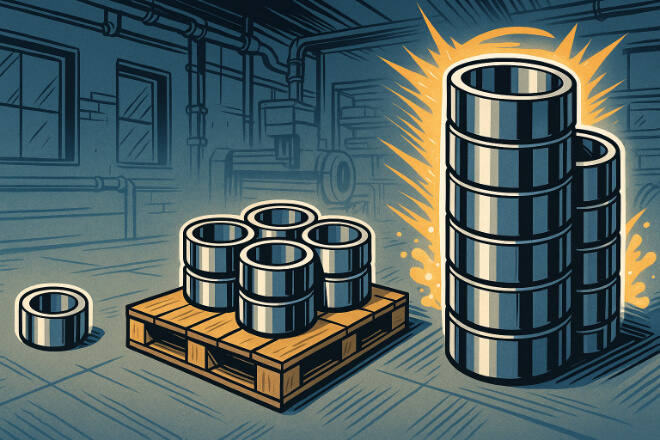

How MOQ and Lead Time Affect Bushing Cost

When sourcing tungsten carbide bushings, the final price is not only determined by the material grade or size. Two factors—MOQ (Minimum Order Quantity) and lead time—play a major role in shaping the total cost. Understanding how these two elements influence pricing helps decision-makers control budgets, avoid delays, and build a more stable supply chain. Why MOQ Matters in Bushing Pricing MOQ is the smallest number of pieces a supplier is willing to produce or ship. For tungsten carbide bushings, MOQ affects cost because carbide manufacturing involves powder preparation, pressing, sintering, machining, and finishing—each requiring setup time and fixed expenses. 1). Why Higher MOQ Lowers Cost Lower machining cost per piece […]