Best Tungsten Carbide Bushings for Centrifugal Pump Shafts

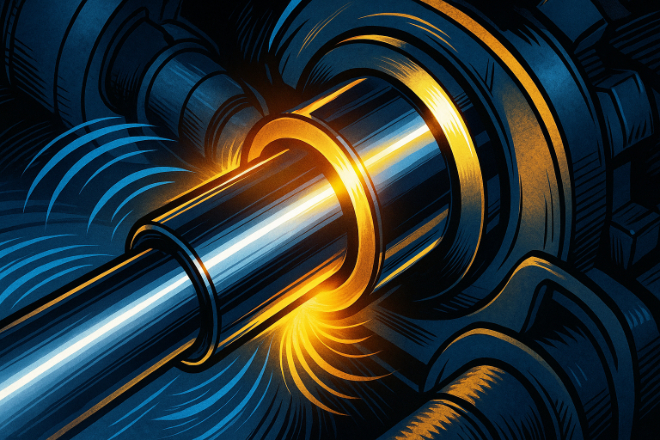

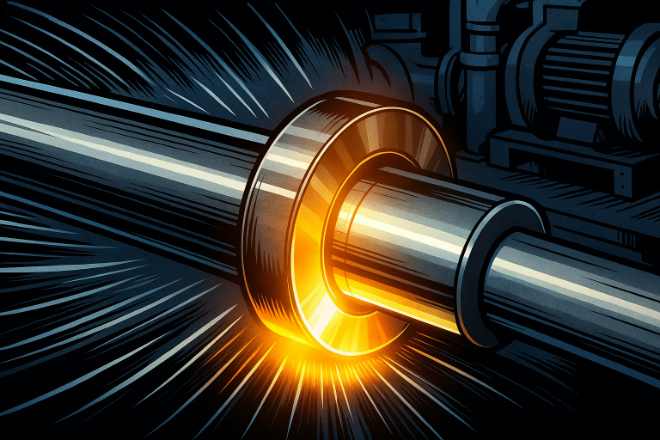

Centrifugal pumps are used across many industries, from chemical plants to power stations and water treatment facilities. Their shafts rotate at high speed and face continuous friction, load, and fluid exposure. Tungsten carbide bushings play an essential role in protecting the shaft and ensuring smooth, long-term operation. This article explains the best tungsten carbide bushing options for centrifugal pump shafts, including grades, designs, and performance differences. Why Tungsten Carbide Is Ideal for Centrifugal Pump Shafts Centrifugal pumps rely on stable shaft rotation. Any friction, vibration, or shaft movement can reduce efficiency and shorten pump life. Tungsten carbide bushings are chosen because they provide: High hardness Excellent wear resistance Low friction […]

Tungsten Carbide Bushings for Electric Submersible Pumps (ESP)

Electric Submersible Pumps (ESP) work in some of the harshest environments in the oil and gas industry. High pressure, abrasive solids, corrosive fluids, and continuous operation make reliability essential. Tungsten carbide bushings play a key role in supporting the pump’s rotating shaft and ensuring long service life. This article explains why tungsten carbide bushings are widely used in ESP systems, what grades work best, and how OEMs can choose the right design for long-term performance. Why Tungsten Carbide Bushings Are Critical in ESP Systems ESP systems run at high speeds and experience constant axial and radial loads. This puts extreme stress on bearings and bushings. Tungsten carbide bushings help maintain […]

Packaging and Shipping Best Practices for Tungsten Carbide Bushings

Tungsten carbide bushings are hard, heavy, and brittle. Even though they offer excellent wear resistance, they can still chip, crack, or deform during transport if the packaging is not correct. This guide explains the best practices for packaging and shipping tungsten carbide bushings so OEMs and industrial users can reduce damage, protect quality, and ensure safe delivery. Why Proper Packaging Matters Tungsten carbide has very high hardness but low flexibility. This combination means it can break if it receives sudden impact during transport. Proper packaging prevents: Cracking or chipping Surface scratches Out-of-round distortion Corrosion from moisture Vibration damage during long-distance shipping For OEMs, damaged bushings lead to delays, production downtime, […]

How to Verify Material Authenticity in Tungsten Carbide Bushings

For OEMs and industrial companies, the quality of a tungsten carbide bushing depends heavily on the authenticity of its material. Poor-quality or mixed-grade carbide can lead to early wear, cracking, leakage, and unexpected downtime. This guide explains practical methods to verify whether a tungsten carbide bushing is made from true, high-grade materials. It is written in simple English and designed for decision-makers who need clear and reliable information. Why Material Authenticity Matters for OEMs The performance of a tungsten carbide bushing comes mainly from the purity of tungsten carbide powder and the quality of the binder (cobalt or nickel). If a supplier uses recycled powder, low-purity carbide, or incorrect binder […]

Total Cost Comparison: Tungsten Carbide vs Conventional Bushings

For many OEMs and industrial companies, the first question when choosing bushings is not only performance, but total cost. Tungsten carbide bushings have a higher purchase price than bronze, steel, polymer, or ceramic bushings. But the total cost over the full life cycle often tells a very different story. This guide compares both options using simple, clear language to help decision-makers understand the real cost difference. What “Total Cost” Really Means for Bushings Many buyers focus only on the purchase price. But for critical rotating equipment, the real cost includes: Purchase cost Installation and labor Downtime Repair cost Replacement frequency Energy consumption Long-term reliability When all these factors are included, […]