Binderless Tungsten Carbide Bushings: When Do They Make Sense?

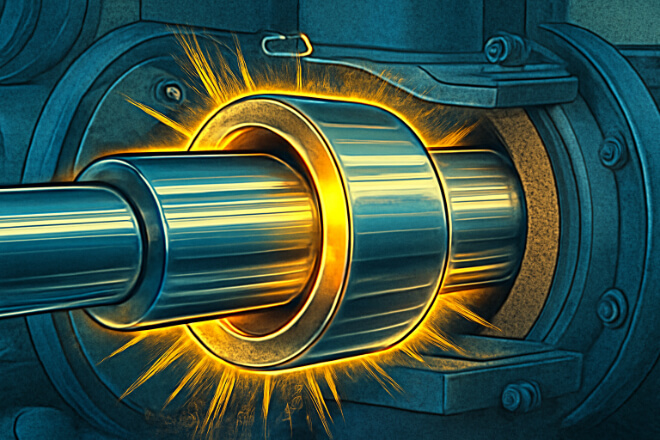

Tungsten carbide bushings are widely used in industries like mining, chemical processing, and oil & gas due to their outstanding hardness, wear resistance, and durability. Traditionally, tungsten carbide bushings are produced with a binder material, such as cobalt or nickel, to provide toughness and help hold the carbide grains together. However, binderless tungsten carbide bushings have emerged as an alternative in certain applications. These bushings are made from pure tungsten carbide without the addition of a binder material. This article explores when binderless tungsten carbide bushings make sense, their benefits, potential drawbacks, and ideal applications. What Are Binderless Tungsten Carbide Bushings? Binderless tungsten carbide bushings are made entirely of tungsten […]

WC-Co vs WC-Ni Tungsten Carbide Bushings: Which Binder for Your Fluid?

In industries such as mining, oil and gas, and chemical processing, pumps are subjected to harsh conditions, including abrasive solids, high pressure, and aggressive fluids. Tungsten carbide bushings are often used to protect pump shafts and bearings in these demanding environments. However, the choice of binder in tungsten carbide, particularly WC-Co (cobalt binder) and WC-Ni (nickel binder), plays a critical role in determining the performance and longevity of these bushings. In this blog, we will compare WC-Co and WC-Ni tungsten carbide bushings to help you decide which binder is best suited for your fluid application. What Is Tungsten Carbide and Why Is It Used in Pumps? Tungsten carbide is a […]

Tungsten Carbide Bushings for High-RPM Compressor Guide Supports

High-RPM compressors are essential components in a variety of industrial applications, including oil and gas, refrigeration, and air compression systems. These compressors operate at high speeds and often handle abrasive, corrosive, and high-pressure fluids. The guide supports in these compressors are key to maintaining stable operations, and their performance is heavily dependent on the materials used. Tungsten carbide bushings are increasingly being specified for high-RPM compressor guide supports due to their exceptional wear resistance, high hardness, and resistance to thermal expansion. This blog explores why tungsten carbide bushings are ideal for high-RPM compressors and how they contribute to better performance, efficiency, and reliability. The Challenges of High-RPM Compressors High-RPM compressors […]

Tungsten Carbide Bushings in Mining Dewatering and Tailings Pumps

Mining dewatering and tailings pumps play a crucial role in the mining industry. These pumps are responsible for moving water, slurry, and tailings away from the mining site, often in harsh, abrasive, and corrosive environments. To ensure optimal performance and longevity, many mining operations use tungsten carbide bushings in their dewatering and tailings pumps. These bushings provide durability, wear resistance, and corrosion protection, which are essential in maintaining pump efficiency and minimizing downtime. Challenges Faced by Dewatering and Tailings Pumps Dewatering and tailings pumps in the mining industry are exposed to some of the most difficult operating conditions. These pumps often deal with: Abrasive materials such as sand, silt, and […]

How Tungsten Carbide Bushings Improve Fertilizer and Acid Transfer Pumps

Fertilizer and acid transfer pumps are essential components in industries such as agriculture and chemical manufacturing. These pumps handle highly corrosive and abrasive substances like concentrated acids, fertilizers, and slurry, often under challenging conditions. To ensure reliability and reduce downtime, many plants use tungsten carbide bushings in their pumps. This article explores how tungsten carbide bushings improve the performance and lifespan of fertilizer and acid transfer pumps, offering benefits in both abrasive resistance and chemical stability. Why Fertilizer and Acid Transfer Pumps Face Unique Challenges Fertilizer and acid transfer pumps are exposed to a combination of high-flow, aggressive chemicals, and particulate matter. These conditions make the pumps vulnerable to several […]