Corrosion Behavior of WC-Ni Bushings in Chloride-Rich Water

WC-Ni (tungsten carbide–nickel) bushings are widely used in pumps, valves, and rotating equipment because they offer strong wear resistance and good toughness. But in chloride-rich water, such as seawater or chemical process fluids, corrosion becomes a major concern. This article explains how WC-Ni bushings behave in chloride environments, what factors drive corrosion, and how to improve their service life in demanding applications. What Are WC-Ni Bushings? WC-Ni bushings are a type of tungsten carbide composite, where nickel acts as the binder material, providing toughness and enhancing the material’s ability to withstand mechanical stress. Tungsten carbide (WC) is extremely hard, offering excellent wear resistance, while the nickel binder improves the overall […]

Selecting Shaft Counterface Materials for Tungsten Carbide Bushings

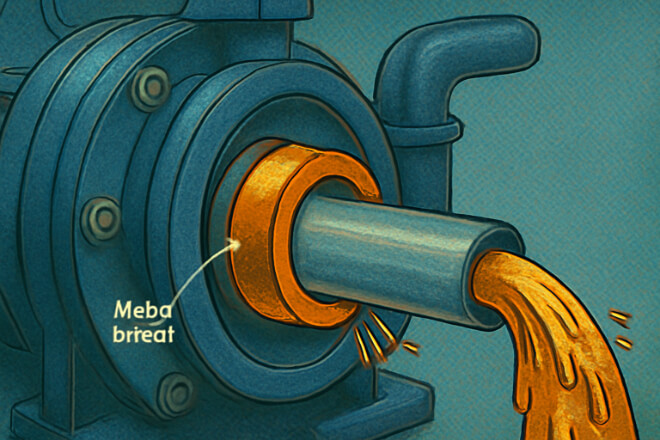

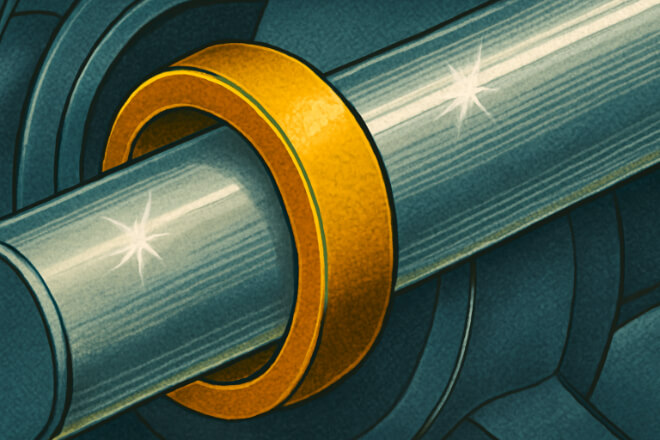

Tungsten carbide bushings are widely used in applications where durability and wear resistance are critical. These bushings are often paired with a shaft, which provides a counterface against which the bushing operates. Selecting the right shaft counterface material is crucial to ensure optimal performance, reduce wear, and extend the service life of both the bushing and the shaft. In this article, we will explore the factors to consider when selecting shaft counterface materials for tungsten carbide bushings. The best material choices for various applications, and how to achieve the perfect match for your system. What Is a Shaft Counterface? The shaft counterface is the surface of the shaft that comes […]

Silicon Carbide vs Tungsten Carbide Bushings in Abrasive Slurry Duty

In industries like mining, chemical processing, and wastewater treatment, pumps often handle abrasive slurries with solid particles and high pressures. To minimize wear and failure, bushings made from durable materials are essential. Silicon carbide (SiC) and tungsten carbide (WC) bushings are popular choices for these demanding applications. Both materials offer excellent wear resistance, but they have unique properties that make them suitable for different environments. This blog will compare SiC and WC bushings, focusing on their performance in abrasive slurry environments and how to choose the right material for your application. What Is Silicon Carbide? Silicon carbide (SiC) is a highly durable material made from silicon and carbon. It is […]

Tungsten Carbide Bushings with TaC/TiC Additions: Abrasion Performance

Tungsten carbide bushings are known for their excellent hardness, wear resistance, and durability, making them ideal for harsh industrial applications. However, adding TaC (Tantalum Carbide) and TiC (Titanium Carbide) to tungsten carbide further improves its abrasion resistance and performance. This blog explores how these additions enhance the abrasion performance of tungsten carbide bushings. And why they are becoming the material of choice for industries requiring superior durability in abrasive environments. Understanding TaC and TiC Additions in Tungsten Carbide Tungsten carbide (WC) is a composite material known for its hardness and wear resistance, making it ideal for use in bushings, bearings, and other industrial components. However, in certain high-demand applications, additional […]

DLC and TiN Coated Tungsten Carbide Bushings: Friction and Wear Benefits

Tungsten carbide bushings are known for their outstanding hardness, wear resistance, and ability to handle extreme conditions. However, even these durable materials can benefit from additional surface treatments. DLC (Diamond-Like Carbon) and TiN (Titanium Nitride) coatings are commonly applied to tungsten carbide bushings to improve their performance by reducing friction and enhancing wear resistance. In this blog, we will explore how these coatings work, their benefits in various applications. And why they make sense for industries looking to extend the life and efficiency of their pumps, valves, and other high-performance components. What Are DLC and TiN Coatings? Both DLC (Diamond-Like Carbon) and TiN (Titanium Nitride) coatings are applied to the […]