Avoiding Edge Chipping on Thin-Wall Tungsten Carbide Bushings

Tungsten carbide bushings are known for their excellent hardness, wear resistance, and durability, making them ideal for demanding applications. However, when tungsten carbide bushings are designed with thin walls, they become more prone to edge chipping. This can negatively impact the bushing’s performance, causing premature wear, misalignment, or even failure. This article will explore the causes of edge chipping in thin-wall tungsten carbide bushings, why it is important to avoid it, and the best practices to prevent this issue during the manufacturing and application phases. What is Edge Chipping? Edge chipping refers to the damage that occurs on the outer edge or corners of a component, typically caused by mechanical […]

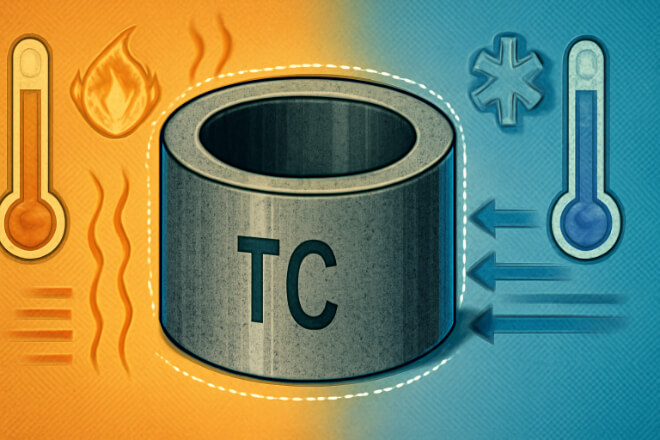

Dimensional Stability of Tungsten Carbide Bushings at High Temperature

Tungsten carbide bushings are essential for high-temperature applications due to their excellent wear resistance and low coefficient of thermal expansion (CTE). Dimensional stability, or the ability to maintain size and shape under temperature fluctuations, is critical to ensure their performance in demanding environments. This article explores how high temperatures affect the dimensional stability of tungsten carbide bushings and provides insights on how to optimize their performance in high-temperature systems. What Is Dimensional Stability? Dimensional stability refers to a material’s ability to retain its shape and size when exposed to temperature changes. In mechanical systems, this is a critical factor because any changes in the dimensions of a bushing or other […]

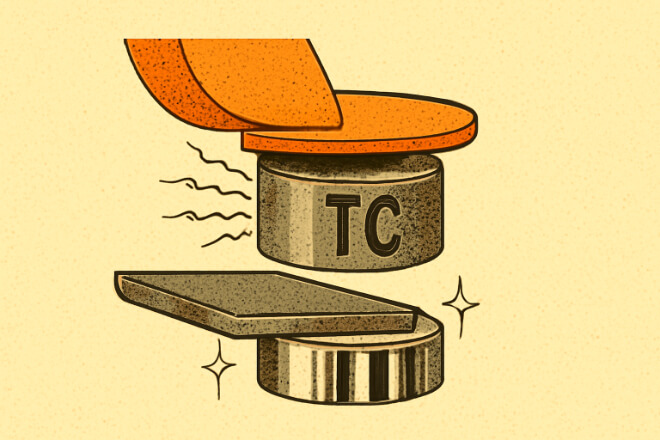

Lapping and Polishing Steps for Mirror-Finish Tungsten Carbide Bushings

Tungsten carbide bushings are known for their exceptional wear resistance, hardness, and durability. However, achieving a mirror-finish on the surface of these bushings is crucial for certain high-performance applications, where minimal friction, enhanced wear resistance, and smooth operation are required. The process of lapping and polishing is essential in achieving this mirror-finish. In this article, we will explore the steps involved in lapping and polishing tungsten carbide bushings to achieve. Amirror-like surface, the tools and techniques required, and why this finish is important for the performance of the bushings. What is Lapping and Polishing? Lapping and polishing are two critical finishing processes used to achieve an ultra-smooth surface on materials […]

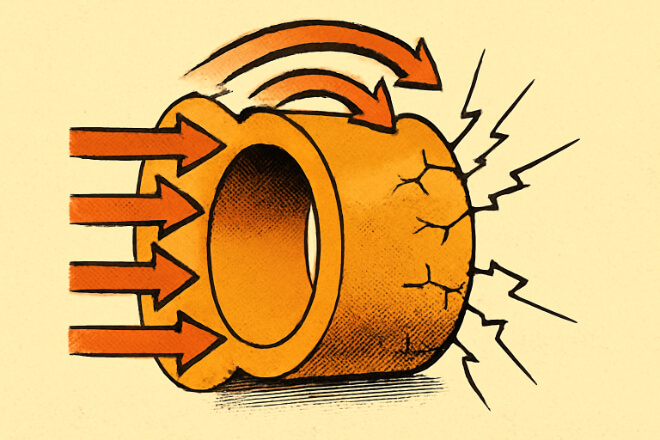

Hoop Stress and Press-Fit Calculations for Tungsten Carbide Bushings

When designing systems that use tungsten carbide bushings, understanding the behavior of materials under stress is essential for ensuring their durability and performance. Hoop stress and press-fit calculations are two critical factors in the design process. Hoop stress refers to the stress experienced by a material under pressure, while press-fit calculations help determine the interference between a bushing and its housing. In this article, we will discuss how to calculate and consider these two factors to ensure the optimal performance of tungsten carbide bushings in demanding applications. What Is Hoop Stress? Hoop stress, also known as circumferential stress, is the stress that acts tangentially to a cylindrical object when it […]

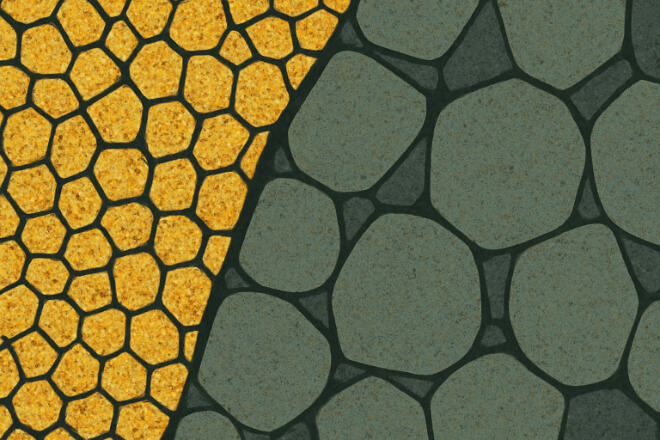

How Grain Size Affects Strength in Tungsten Carbide Bushings

Tungsten carbide bushings are widely used in applications that demand high wear resistance and durability. One critical factor influencing their performance is grain size. The grain size of tungsten carbide directly impacts its strength, toughness, and wear resistance. In this article, we will explore how grain size affects the strength of tungsten carbide bushings. How to control it during manufacturing, and how it influences bushing performance in various industrial applications. What Is Grain Size in Tungsten Carbide? Grain size refers to the size of the individual particles or grains that make up a material. In tungsten carbide, the grains are composed of tungsten carbide (WC) particles bound together by a […]