On-Site Inspection of Tungsten Carbide Bushings: ID, OD, and Roundness

Tungsten carbide bushings are essential for high-performance applications, but ensuring their quality requires accurate on-site inspection. Measuring critical dimensions like internal diameter (ID), outer diameter (OD), and roundness is vital for maintaining performance and preventing failure. This article discusses the importance of on-site inspection and best practices for ensuring the bushings meet the required specifications. The Importance of On-Site Inspection On-site inspection of tungsten carbide bushings ensures that they meet specific dimensional and geometrical tolerances required for optimal performance. Checking critical dimensions like ID, OD, and roundness helps identify any potential issues early, reducing the risk of operational failure and extending the lifespan of your equipment. Why On-Site Inspection Matters: […]

Alignment Checks to Prevent Out-of-Round Wear on WC Bushings

Tungsten carbide bushings are valued for their durability and wear resistance. However, if improperly aligned, they can suffer from out-of-round wear, which leads to uneven friction and premature failure. This article will explain the causes of out-of-round wear, how misalignment affects the bushing, and best practices for ensuring proper alignment to prevent these issues. What is Out-of-Round Wear? Out-of-round wear occurs when a component, such as a tungsten carbide bushing, is no longer perfectly circular due to uneven wear or pressure. This can happen if the bushing is misaligned during installation or during operation, causing the bushing to rotate unevenly within its housing or on the shaft. Why Out-of-Round Wear […]

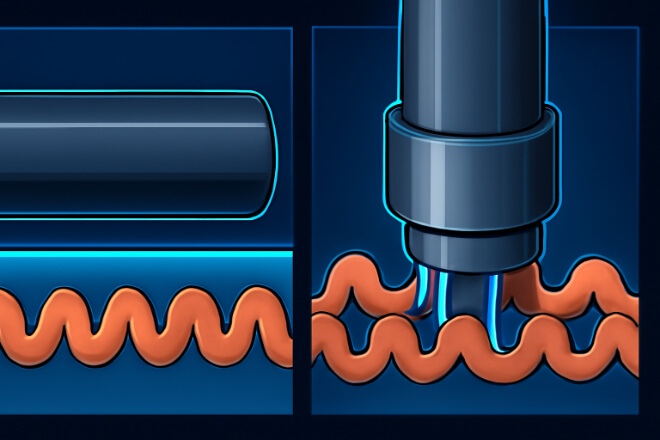

How to Press-Fit Tungsten Carbide Bushings Without Inducing Cracks

Tungsten carbide bushings are known for their exceptional durability, hardness, and wear resistance, making them ideal for high-performance applications. However, during installation, press-fitting tungsten carbide bushings into housings or shafts can sometimes lead to cracks or fractures, especially if the fit is too tight or improper installation techniques are used. This article will explore how to press-fit tungsten carbide bushings effectively, how to prevent cracking, and the best practices for ensuring that the bushing maintains its integrity throughout the installation process. What Is Press-Fitting? Press-fitting is the process of installing a bushing into a housing or onto a shaft by applying force to create an interference fit. The goal is […]

Lubrication Plans for Tungsten Carbide Bushings in Boundary Conditions

Tungsten carbide bushings are known for their durability and wear resistance. However, in boundary lubrication conditions, where the lubricant film is too thin to fully separate the bushing from the mating surface, ensuring proper lubrication is essential to prevent friction and wear. This article will discuss the role of lubrication in boundary conditions, the factors that affect its performance, and best practices for maintaining tungsten carbide bushings in these environments. What is Boundary Lubrication? Boundary lubrication occurs when the lubricant film between two surfaces is too thin to fully separate them. Under these conditions, the surfaces experience some degree of direct contact, resulting in increased friction and wear. This situation […]

Non-Magnetic Requirements: When to Choose WC-Ni Bushings

When designing mechanical systems, non-magnetic materials are often a critical consideration. Whether in industries like electronics, medical equipment, or mining, certain applications require bushings that do not interfere with magnetic fields. In such cases, WC-Ni (Tungsten Carbide-Nickel) bushings become a key material choice. These bushings provide the strength and wear resistance of tungsten carbide while being non-magnetic, making them ideal for specific applications. This article will explore the situations when WC-Ni bushings are preferred, the benefits they offer, and how to select them for your application. What Are WC-Ni Bushings? WC-Ni bushings are made by combining tungsten carbide (WC) with a nickel (Ni) binder. Tungsten carbide, known for its exceptional […]