How to Pair Tungsten Carbide Bushings with Mechanical Seal Upgrades

Tungsten carbide bushings are crucial components in industrial applications, providing wear resistance and durability in harsh environments. Pairing them with the right mechanical seals is essential for ensuring system reliability and preventing leakage. Upgrading mechanical seals can significantly enhance the performance of tungsten carbide bushings, leading to longer operational lifespans and reduced maintenance costs. This article explores how to successfully pair tungsten carbide bushings with mechanical seal upgrades for optimal performance. Understanding the Role of Tungsten Carbide Bushings and Mechanical Seals Before diving into pairing strategies, it’s important to understand the individual roles of tungsten carbide bushings and mechanical seals in industrial systems. 1). Tungsten Carbide Bushings: Durability: Tungsten carbide […]

Vibration Diagnostics: Saving Tungsten Carbide Bushings from Premature Failure

Tungsten carbide bushings are widely used in industries requiring high durability, wear resistance, and performance in harsh conditions. However, even the toughest materials can suffer from premature failure due to vibration. In industrial applications, vibration diagnostics play a critical role in identifying issues before they lead to costly repairs or replacements. This article explores the importance of vibration diagnostics, how vibrations affect tungsten carbide bushings, and the best practices for detecting and preventing damage. The Impact of Vibration on Tungsten Carbide Bushings Tungsten carbide bushings are designed to withstand harsh operational conditions, but prolonged or excessive vibration can cause damage over time. Vibration-induced wear can lead to several issues that […]

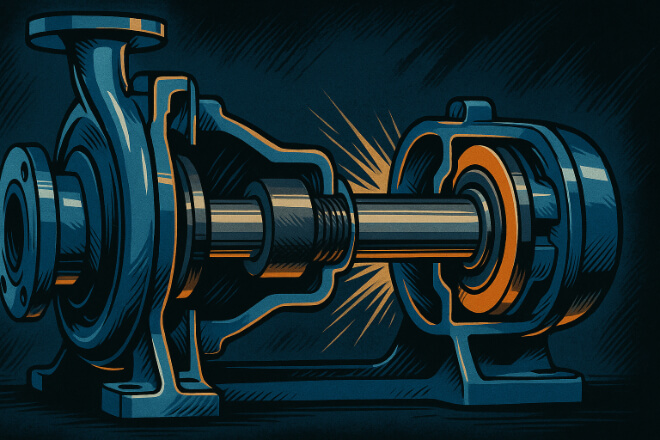

Preventing Cavitation and Erosion Damage to Tungsten Carbide Bushings

Tungsten carbide bushings are known for their durability, but they can still suffer from cavitation and erosion damage in high-demand environments. Cavitation occurs when pressure fluctuations cause bubbles to form and collapse, damaging the bushing surface. Erosion happens when abrasive particles wear down the bushing over time. This article will discuss how cavitation and erosion affect tungsten carbide bushings, their causes, and best practices to prevent damage and extend bushing lifespan. What is Cavitation and Erosion Damage? Before diving into prevention methods, it’s important to understand the specific nature of cavitation and erosion damage. 1). Cavitation Cavitation is the formation and collapse of vapor bubbles in a fluid. When these […]

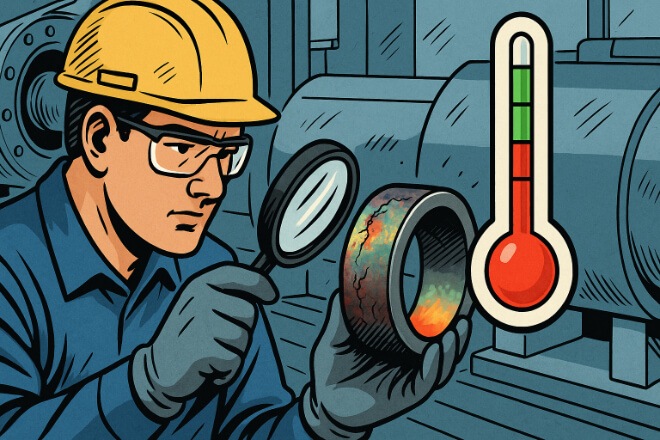

Temperature Limits and Cooling Strategies for WC Bushings in Service

Tungsten carbide (WC) bushings are highly durable and capable of withstanding extreme conditions, making them ideal for heavy-duty applications. However, like any material, they have temperature limits that must be respected to ensure optimal performance and longevity. Excessive heat can cause thermal expansion, wear, and eventually premature failure of the bushing. This article will explore the temperature limits of WC bushings, the impact of high temperatures on their performance, and effective cooling strategies to prevent damage during service. Understanding the Temperature Limits of WC Bushings Tungsten carbide bushings have excellent thermal properties, but they are not immune to the effects of high temperatures. Understanding their temperature limits is crucial for […]

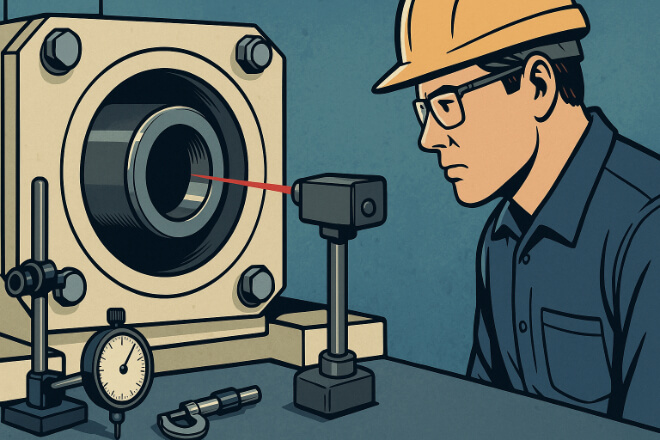

Field Guide: Removing and Replacing Tungsten Carbide Bushings Safely

Tungsten carbide bushings are essential for high-performance systems, but improper removal and replacement can cause damage. Ensuring safe and efficient procedures during bushing removal and installation is crucial to prevent wear or fractures. This guide provides a step-by-step approach to safely remove and replace tungsten carbide bushings, highlighting key tools and best practices for a smooth process. Why Proper Removal and Replacement of Tungsten Carbide Bushings Is Critical Tungsten carbide bushings are crucial for ensuring the smooth functioning of mechanical systems. However, improper removal and replacement can lead to damage to the bushing, housing, or shaft, which can compromise system performance and cause operational downtime. Why Safe Removal and Replacement […]