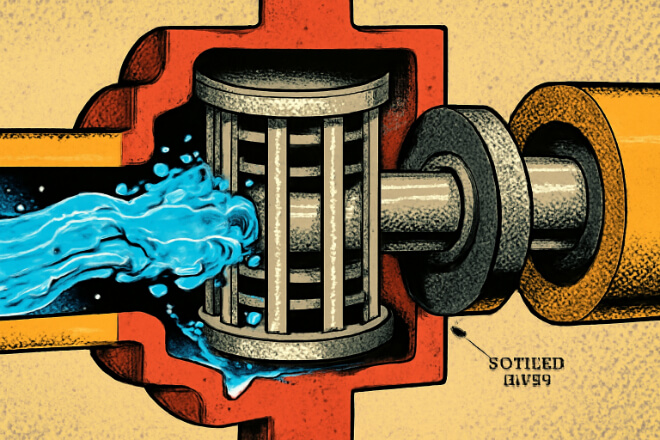

Flow Cage and Sleeve Assemblies: Integrating Tungsten Carbide Bushings

Flow cage and sleeve assemblies are essential components in many industrial applications, including pumps, compressors, and turbines. These assemblies ensure smooth operation by containing fluid flow, reducing friction, and supporting moving parts. Tungsten carbide bushings are increasingly integrated into these assemblies due to their exceptional wear resistance, durability, and performance in harsh environments. In this blog, we will explore how tungsten carbide bushings enhance flow cage and sleeve assemblies and why they are the ideal choice for demanding applications. Understanding Flow Cage and Sleeve Assemblies Flow cage and sleeve assemblies are used to contain, guide, and support rotating components in fluid systems. The sleeve typically acts as a housing for […]

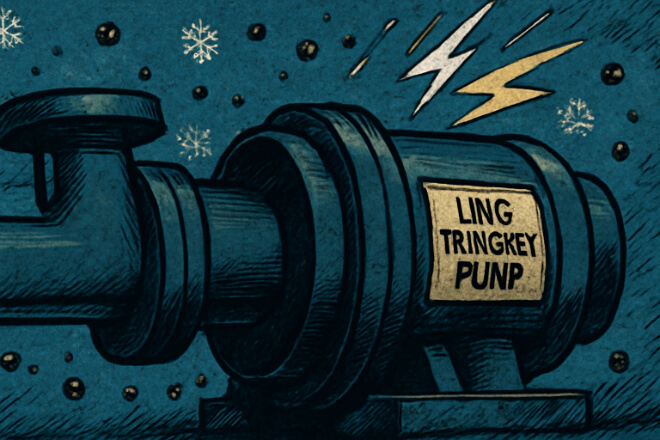

Tungsten Carbide Bushings for Cryogenic LNG Transfer Pumps

LNG (Liquefied Natural Gas) transfer pumps are crucial in transporting LNG at extremely low temperatures, which can create significant challenges for the materials used in pump components. Tungsten carbide bushings are an ideal solution for these pumps due to their exceptional wear resistance, low thermal expansion, and durability at cryogenic temperatures. This blog explores the importance of using tungsten carbide bushings in cryogenic LNG transfer pumps and how they help improve pump performance and lifespan. Challenges in Cryogenic LNG Transfer Pump Applications Cryogenic LNG transfer pumps operate in harsh environments, with temperatures reaching as low as -162°C (-260°F). These extreme conditions pose several challenges for pump components: 1). Low Temperature […]

ESP Thrust Bearing Bushings: Why Tungsten Carbide Excels in Sand-Laden Water

Tungsten carbide bushings are essential components in Electric Submersible Pumps (ESPs), particularly in harsh environments like sand-laden water. These bushings offer exceptional durability, wear resistance, and corrosion protection. As abrasive particles in the water can cause wear and damage to pump components, tungsten carbide bushings provide the reliability needed for extended operational life. This blog explores why tungsten carbide is ideal for ESP thrust bearings and how it ensures better performance in such challenging conditions. Challenges of Sand-Laden Water in ESP Systems Sand-laden water can cause significant challenges in ESP systems. The presence of sand and other abrasive particles in the water increases the wear rate of pump components, particularly […]

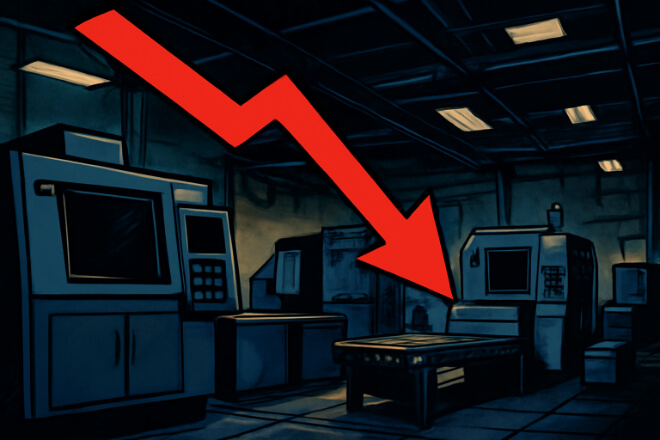

Total Cost of Downtime: Calculating ROI for Tungsten Carbide Bushings

Tungsten carbide bushings are known for their durability, wear resistance, and high performance in harsh environments. However, even the best-quality bushings can fail, leading to equipment downtime, costly repairs, and lost productivity. Calculating the total cost of downtime due to failed bushings and measuring the return on investment (ROI) of high-quality tungsten carbide bushings is essential for companies aiming to make informed decisions. In this blog, we’ll explore how to calculate the total cost of downtime, the role of tungsten carbide bushings in reducing this cost, and how to determine ROI for your bushing investments. The Importance of Downtime Costs in Manufacturing In any manufacturing or industrial operation, downtime can […]

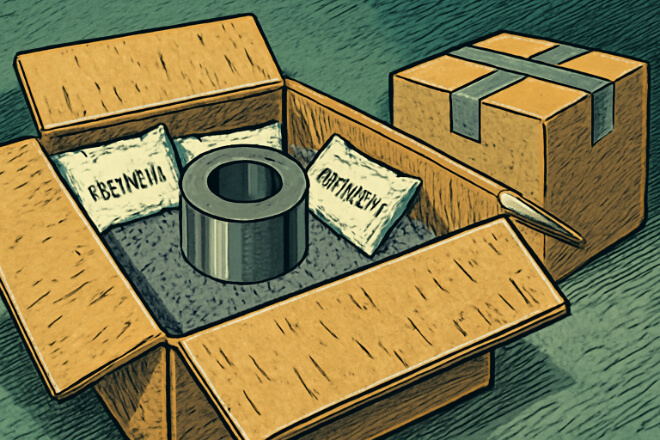

Export Packaging for Tungsten Carbide Bushings: Moisture and Shock Protection

Tungsten carbide bushings are high-performance components used in demanding industries such as mining, pumps, and machinery. These bushings offer excellent wear resistance, but they need to be properly protected during shipping to ensure they reach their destination without damage. Two critical factors to consider when packaging tungsten carbide bushings for export are moisture and shock protection. In this blog, we’ll explore best practices for packaging these bushings to prevent moisture-related damage and minimize the risk of shock during transportation, helping ensure the safe delivery of high-quality products. Why Moisture and Shock Protection Matter for Tungsten Carbide Bushings Tungsten carbide bushings are highly durable, but like any precision component, they are […]