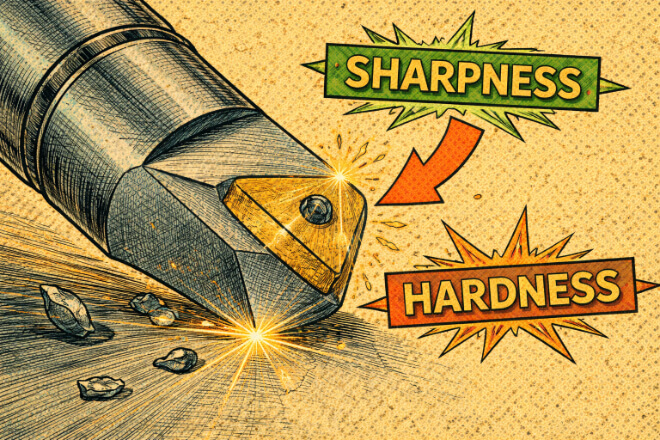

What Are Tungsten Carbide Tips and How Do They Work?

Tungsten carbide tips are widely used in various industrial applications due to their exceptional hardness and wear resistance. These tips are commonly found in tools that require high durability, such as cutting tools, drill bits, and mining equipment. Understanding what tungsten carbide tips are and how they work is essential for making the right choice in applications that demand precision, strength, and long-lasting performance. This blog will explain the basics of tungsten carbide tips, how they function, and why they are an ideal solution for industries requiring high-performance components. What Are Tungsten Carbide Tips? Tungsten carbide is a compound made from tungsten and carbon. It is one of the hardest […]

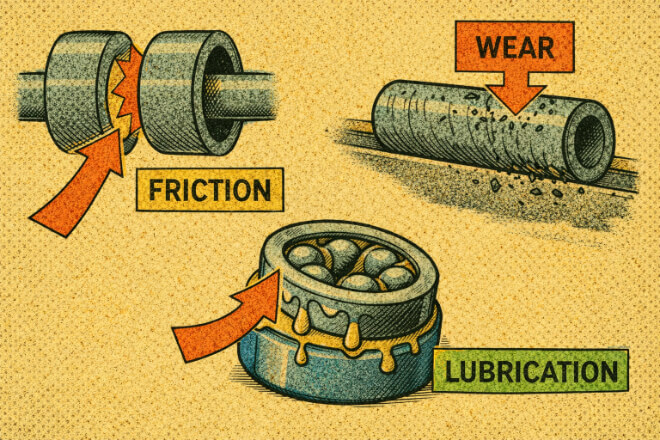

Tribology Basics for Engineers Using Tungsten Carbide Bushings

Tribology is the science of friction, wear, and lubrication, and it plays a crucial role in the performance of mechanical systems. In applications where components are subjected to heavy loads and harsh conditions, understanding tribology is essential for improving the reliability and lifespan of the system. Tungsten carbide bushings are widely used in these applications due to their high wear resistance and toughness. In this blog, we will explore the basics of tribology as it relates to tungsten carbide bushings and how engineers can apply tribological principles to enhance performance and prevent premature failure. What is Tribology? Tribology is the study of how surfaces interact in relative motion. It involves […]

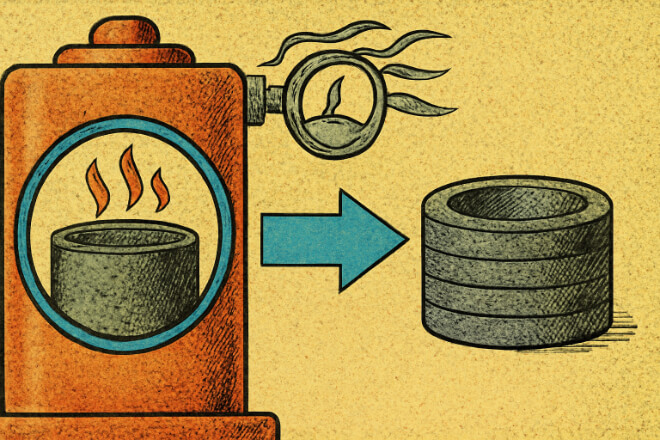

Hot Isostatic Pressing (HIP) and the Density of Tungsten Carbide Bushings

Tungsten carbide bushings are essential components used in demanding industrial applications, including pumps, valves, and machinery. One of the key factors determining the performance of these bushings is their density, which directly affects their hardness, wear resistance, and overall durability. Hot Isostatic Pressing (HIP) is a critical process used to improve the density of tungsten carbide bushings. This blog explores how HIP works, how it affects the density of tungsten carbide bushings, and why this process is crucial for enhancing the performance of industrial components. What is Hot Isostatic Pressing (HIP)? Hot Isostatic Pressing (HIP) is a manufacturing process that involves applying high temperature and pressure to materials, typically in […]

Carbide Seal Rings: Specs, Grades, and Fast Customization at Retop (Product Hub)

Carbide seal rings play a critical role in a wide range of industries, including pumps, compressors, and other machinery that operates under high pressure and temperatures. They provide reliable sealing solutions by preventing fluid leakage, ensuring system efficiency, and prolonging the lifespan of the equipment. At Retop (Product Hub), we offer carbide seal rings with various specs and grades tailored to meet your specific needs. This blog explores the key specifications, grades, and the advantages of fast customization available at Retop for carbide seal rings. What Are Carbide Seal Rings? Carbide seal rings are components used in sealing applications to prevent fluid leakage, reduce friction, and improve system performance. They […]

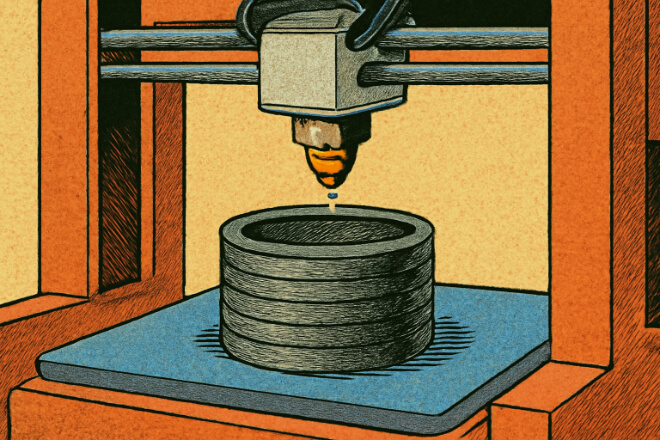

Additive Manufacturing Trends for Tungsten Carbide Bushing Preforms

Additive manufacturing (AM), also known as 3D printing, is transforming the way industries produce parts, including tungsten carbide bushings. As the demand for more complex and customized components increases, AM is emerging as a valuable solution for creating tungsten carbide bushing preforms. These preforms serve as the foundation for the final bushing, offering improved design flexibility, reduced material waste, and enhanced performance. In this blog, we’ll explore the latest trends in additive manufacturing for tungsten carbide bushing preforms and how these innovations are benefiting industries that rely on high-performance components. What is Additive Manufacturing for Tungsten Carbide Bushing Preforms? Additive manufacturing involves creating parts layer by layer from a digital […]