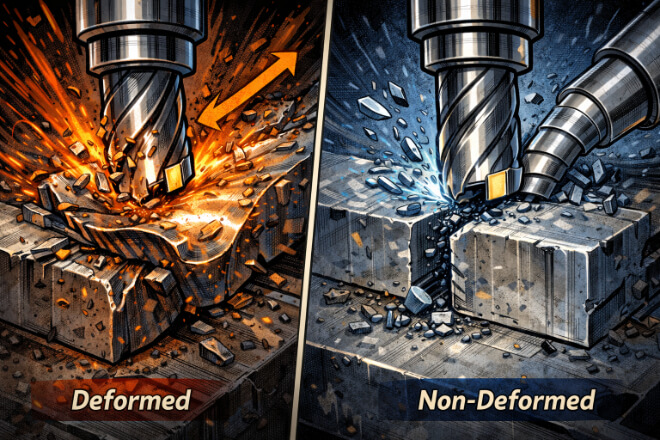

How Tungsten Carbide Tips Help Prevent Material Deformation During Cutting

In cutting and machining operations, one of the key challenges is preventing material deformation. Deformation can lead to poor-quality cuts, additional processing time, and higher costs. Tungsten carbide tips are widely used to combat this issue due to their exceptional hardness and precision. This blog will explore how tungsten carbide tips help prevent material deformation during cutting, leading to improved tool performance, higher product quality, and cost savings. What Is Material Deformation and Why Is It a Problem? Material deformation refers to any change in the shape or structure of a material that occurs during cutting or machining. In cutting operations, deformation can take many forms, including bending, warping, or […]

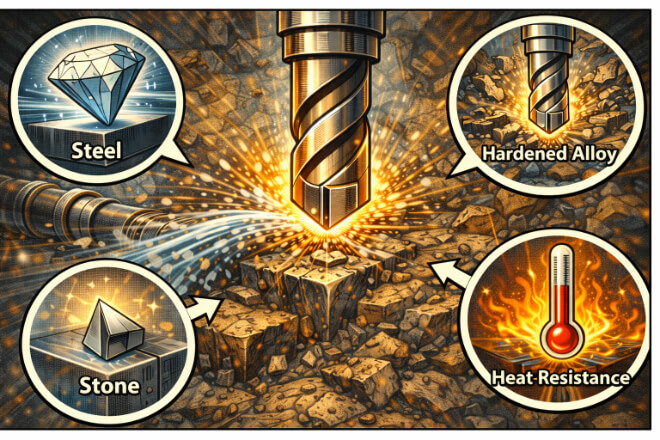

Performance Testing of Tungsten Carbide Tips for Different Applications

Tungsten carbide tips are essential tools in many industries for their durability, precision, and wear resistance. To ensure they perform at their best, performance testing is crucial. By testing carbide tips under various conditions, businesses can select the best tools for their specific applications. This blog explores the importance of performance testing, key factors influencing carbide tip performance, and how it can enhance the longevity and accuracy of tools in various industries. Why Performance Testing of Tungsten Carbide Tips Is Essential Performance testing is the process of evaluating how a tool, in this case, tungsten carbide tips, performs under various operating conditions. It helps determine the tool’s effectiveness, durability, and […]

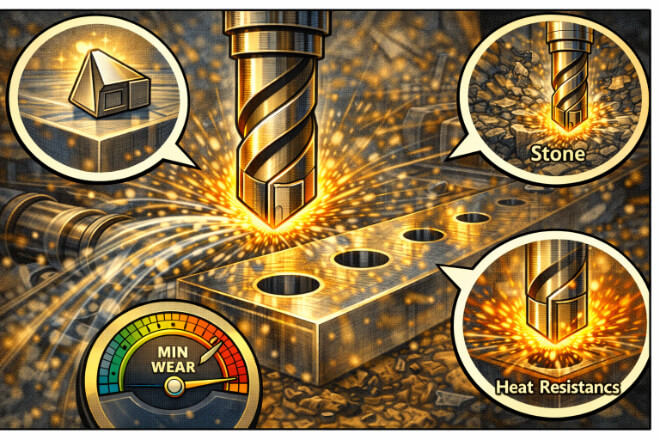

How Tungsten Carbide Tips Improve Drilling and Cutting Accuracy

In industries like mining, manufacturing, and construction, drilling and cutting accuracy are essential for ensuring high-quality results and minimizing waste. Tungsten carbide tips have become the go-to solution for achieving precise cuts and holes due to their exceptional hardness, durability, and resistance to wear. This blog will explore how tungsten carbide tips improve drilling and cutting accuracy, and why they are a wise investment for businesses seeking consistent, high-performance results. What Makes Tungsten Carbide Tips Ideal for Accurate Drilling and Cutting? Tungsten carbide tips are widely used in various industries for drilling and cutting due to their unique properties that enhance both performance and accuracy. These properties are key to […]

Improving Tool Life with Tungsten Carbide Tips: Key Techniques

In the world of manufacturing and machining, tool life is a critical factor that impacts productivity, cost, and overall efficiency. Tungsten carbide tips are known for their durability and precision, making them a popular choice in various industries. However, to get the most out of tungsten carbide tools, it’s essential to implement the right techniques that maximize their lifespan. In this blog, we’ll explore key strategies and best practices for improving tool life with tungsten carbide tips, ensuring that your tools perform at their best for longer. Understanding Tungsten Carbide Tips and Their Durability Tungsten carbide is one of the hardest materials used in cutting tools. The exceptional hardness and […]

Tungsten Carbide Tips in High-Pressure and High-Torque Environments

In industries like oil and gas, mining, and heavy manufacturing, tools are subjected to extreme conditions such as high pressure and high torque. Under these conditions, it’s essential to use cutting tools that maintain performance and durability. Tungsten carbide tips are the ideal choice for such environments due to their superior hardness, wear resistance, and toughness. In this blog, we will discuss how tungsten carbide tips perform in high-pressure and high-torque environments and why they are the go-to solution for these demanding applications. Understanding High-Pressure and High-Torque Environments High-pressure and high-torque environments are characterized by intense mechanical stresses, extreme temperatures, and the need for precision. These environments are common in […]