The Role of Tungsten Carbide Tips in Drilling for Oil and Gas

In the oil and gas industry, drilling is one of the most critical operations for exploring and extracting valuable resources from deep beneath the Earth’s surface. Tungsten carbide tips are integral to drilling tools due to their durability, hardness, and wear resistance. These properties make tungsten carbide tips essential for high-performance drilling in tough, abrasive environments. In this blog, we will explore the role of tungsten carbide tips in oil and gas drilling, how they improve drilling efficiency, and why they are the preferred choice for drill bits in this challenging industry. Why Tungsten Carbide Tips Are Essential for Oil and Gas Drilling The harsh conditions encountered during oil and […]

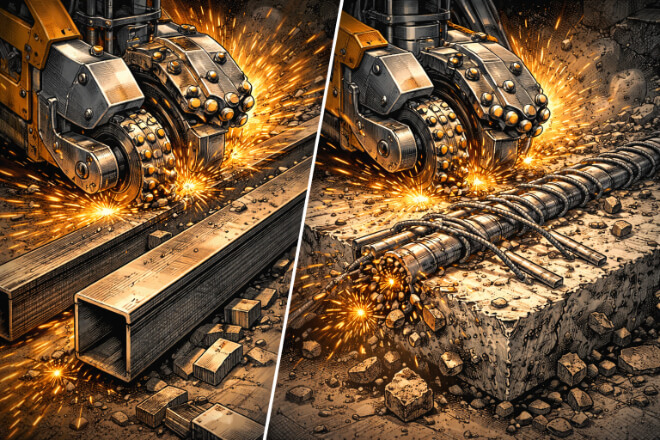

Tungsten Carbide Tips for Rebar and Wire Cutting: Impact and Durability

In industries such as construction, manufacturing, and metalworking, cutting rebar and wire accurately and efficiently is crucial. The cutting tools used must withstand constant wear and high-impact forces. Tungsten carbide tips are often the best choice for these applications due to their outstanding impact resistance, durability, and wear resistance. In this blog, we will explore the benefits of using tungsten carbide tips for rebar and wire cutting, and how they contribute to improving performance and extending tool life in harsh environments. Why Tungsten Carbide Tips Are Ideal for Rebar and Wire Cutting Rebar and wire cutting can be challenging due to the hardness and toughness of the materials involved. Tungsten […]

How Tungsten Carbide Tips Perform in Woodworking Machines

In woodworking, achieving precision and efficiency is critical for creating high-quality finished products. Woodworking machines, from saws to routers and planers, require tools that can withstand wear, maintain sharpness, and deliver consistent results. Tungsten carbide tips have become the preferred choice in woodworking applications due to their hardness, durability, and precision. This blog will explore how tungsten carbide tips perform in woodworking machines and why they are an excellent investment for manufacturers looking to improve productivity and reduce tool replacement costs. Why Tungsten Carbide Tips Are Ideal for Woodworking Machines Tungsten carbide tips are highly valued in the woodworking industry for their outstanding performance and ability to withstand the harsh […]

How Tungsten Carbide Tips Compare to Ceramic and Steel in Tough Cutting Jobs

In industries that require tough cutting, such as metalworking, construction, and automotive manufacturing, the choice of cutting tool material can significantly impact efficiency, tool life, and operational costs. Among the most commonly used materials for cutting tools are tungsten carbide, ceramic, and steel. Each material has unique properties that make it suitable for certain applications, but how do they compare in tough cutting jobs? This blog will compare tungsten carbide tips to ceramic and steel in terms of performance, durability, and cost-effectiveness in demanding cutting tasks. Tungsten Carbide Tips: The Preferred Choice for Tough Cutting Jobs Tungsten carbide is widely considered the best material for cutting tools used in tough […]

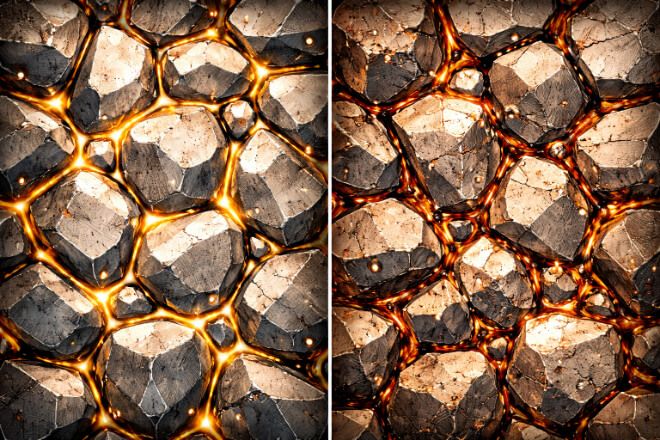

Tungsten Carbide Tips with Nickel vs Cobalt Binders: Which Performs Better?

Tungsten carbide tips are widely used in cutting, drilling, and wear-resistant tools. However, not all tungsten carbide tips are the same. One key difference is the binder material used to hold the tungsten carbide grains together. The two most common binders are nickel (Ni) and cobalt (Co). Each binder changes the performance of the material and affects tool life, corrosion resistance, toughness, and cost. This blog compares nickel-bonded and cobalt-bonded tungsten carbide tips to help decision-makers choose the right option for their applications. Why Binder Material Matters in Tungsten Carbide Tips Tungsten carbide is extremely hard, but without a binder it would be brittle. The binder controls several critical material […]