The Importance of Regular Maintenance for Tungsten Carbide Tips

Tungsten carbide tips are highly durable and used in demanding industrial applications such as cutting, drilling, and machining. However, even the toughest materials require regular maintenance to ensure they continue performing at their best. Proper maintenance can significantly extend the lifespan of tungsten carbide tips, improve efficiency, and reduce downtime in production. This blog will explore why regular maintenance is essential for tungsten carbide tips and provide best practices for maintaining these valuable tools. Why Regular Maintenance is Crucial for Tungsten Carbide Tips Tungsten carbide is known for its hardness and wear resistance, but it is still prone to damage from wear, impact, and thermal shock over time. Without proper […]

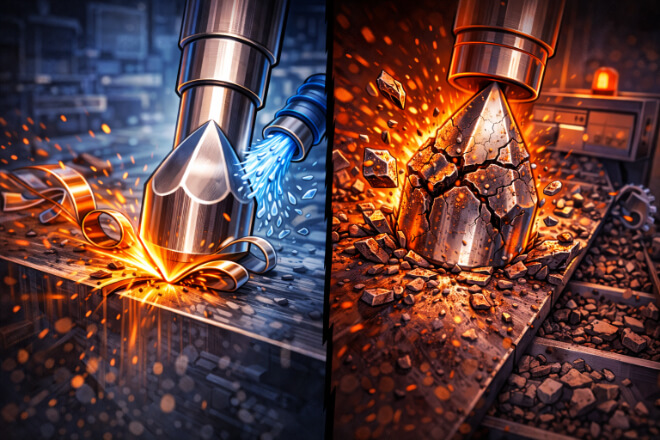

How to Prevent Tungsten Carbide Tips from Cracking or Chipping

Tungsten carbide tips are highly valued for their hardness and wear resistance. However, despite their durability, they are prone to cracking or chipping under certain conditions. In industries that rely on cutting and drilling tools, preventing such damage is critical for maintaining tool performance and reducing downtime. This blog will explore practical strategies for preventing tungsten carbide tips from cracking or chipping, ensuring long-term effectiveness and cost-efficiency. Why Do Tungsten Carbide Tips Crack or Chip? Tungsten carbide tips are incredibly hard, but this hardness also makes them more brittle, which means they are more susceptible to cracking or chipping under stress. Several factors contribute to this vulnerability: High Impact Forces: […]

Evaluating the Abrasive Wear Resistance of Tungsten Carbide Tips

Tungsten carbide tips are widely regarded for their exceptional hardness and wear resistance. In industries where cutting tools face constant abrasion, such as mining, manufacturing, and machining, understanding the abrasive wear resistance of tungsten carbide is crucial. This blog will explore how tungsten carbide tips handle abrasive wear, the factors that influence their performance, and why they are a preferred choice in challenging industrial applications. What is Abrasive Wear Resistance? Abrasive wear refers to the degradation of a material due to contact with a harder surface. This often happens when a tool is in constant friction with another material, leading to the loss of material from the tool’s surface. The […]

The Impact of Thermal Shock on Tungsten Carbide Tips: What You Need to Know

Tungsten carbide is a widely used material for industrial cutting tools due to its hardness and wear resistance. However, even the most durable materials can face challenges in certain conditions. One of the most damaging factors for tungsten carbide tips is thermal shock. When tungsten carbide tools are exposed to rapid temperature changes, they can suffer from cracking or breakage. This blog will explore the impact of thermal shock on tungsten carbide tips, what causes it, and how to mitigate its effects in industrial applications. What is Thermal Shock? Thermal shock occurs when a material experiences a rapid change in temperature, causing it to expand or contract too quickly. This […]

Tungsten Carbide Tips vs Diamond-Coated Tips: Which Is Better for Industrial Applications?

In industrial applications where cutting and drilling tools endure extreme conditions, choosing the right material is crucial for ensuring performance and longevity. Tungsten carbide tips and diamond-coated tips are two popular options. Both offer exceptional hardness and durability, but their specific advantages make them more suitable for certain tasks. In this blog, we will compare tungsten carbide tips and diamond-coated tips to determine which material is better suited for various industrial applications. What are Tungsten Carbide Tips? Tungsten carbide is a compound made from tungsten and carbon, known for its exceptional hardness and wear resistance. It is often used in cutting tools, drilling equipment, and mining tools. Tungsten carbide tips […]