The Cost of Replacing Tungsten Carbide Tips: How to Maximize Your Budget

When managing industrial operations, especially in industries like manufacturing, mining, and construction, keeping tool costs under control is crucial. Tungsten carbide tips are known for their durability and performance, but they come at a higher initial cost compared to other materials. However, the cost of replacing these tips is a significant factor to consider when managing a budget. This blog will explore the real cost of replacing tungsten carbide tips and how businesses can maximize their budgets by reducing replacement frequency, improving tool lifespan, and minimizing downtime. Understanding the Cost of Replacing Tungsten Carbide Tips Tungsten carbide tips are designed to withstand extreme wear and tear, offering superior performance and […]

Understanding the Price Variability of Tungsten Carbide Tips Across Suppliers

Tungsten carbide tips are essential tools in industries ranging from manufacturing to mining and construction due to their exceptional hardness, durability, and wear resistance. However, the price of these tools can vary significantly across suppliers, even for seemingly identical products. Understanding the factors that influence this price variability is crucial for decision-makers looking to optimize their tool procurement and maximize their budgets. In this blog, we’ll explore the reasons behind the price differences of tungsten carbide tips, how to navigate them, and how companies can make informed purchasing decisions to get the best value for their money. Factors Influencing Tungsten Carbide Tip Pricing The price of tungsten carbide tips can […]

Why Tungsten Carbide Tips Are Worth the Investment in Heavy Industries

In heavy industries, where the demand for durable and high-performance tools is crucial, tungsten carbide tips have proven to be a valuable investment. Although they come with a higher initial cost, their superior properties provide long-term benefits that outweigh the upfront price. This blog will explore why tungsten carbide tips are worth the investment for companies in heavy industries like mining, construction, and manufacturing. By understanding the cost savings, durability, and performance benefits of tungsten carbide tips, industrial decision-makers can make more informed choices that contribute to greater efficiency and profitability. Understanding Tungsten Carbide and Its Benefits Tungsten carbide is one of the hardest materials available, composed of tungsten and […]

How Tungsten Carbide Tips Improve Return on Investment for Industrial Tools

In today’s competitive industrial landscape, maximizing the return on investment (ROI) for tools is crucial for maintaining profitability and operational efficiency. Tungsten carbide tips have become a go-to solution for industries requiring high-performance tools, particularly in demanding applications. This blog explores how tungsten carbide tips can significantly improve ROI by reducing maintenance costs, increasing tool lifespan, enhancing productivity, and minimizing downtime. What is Tungsten Carbide and Why It Matters? Tungsten carbide is an extremely hard material commonly used for industrial tools due to its exceptional durability, wear resistance, and high temperature tolerance. Tools equipped with tungsten carbide tips are capable of handling the toughest tasks, including cutting, drilling, and grinding, […]

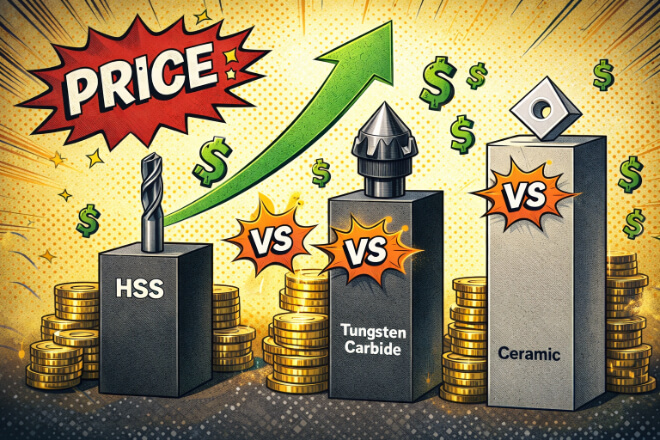

Comparing the Initial and Long-Term Costs of Tungsten Carbide Tips

Tungsten carbide tips are a popular choice in many industries, from mining to construction and manufacturing, due to their durability, hardness, and wear resistance. However, when it comes to budgeting for these tools, it’s important to consider both the initial and long-term costs. This blog explores the financial aspects of investing in tungsten carbide tips, comparing their upfront costs with the savings they offer in terms of long-term performance, maintenance, and replacement. Initial Costs of Tungsten Carbide Tips Tungsten carbide tips are generally more expensive upfront compared to tools made from other materials such as high-speed steel (HSS) or ceramics. These costs are primarily due to the raw material itself—tungsten […]