How Tungsten Carbide Tips Are Used in Saw Blades for Metal Cutting

Cutting metal is one of the most demanding tasks for any cutting tool. Whether it’s structural steel, aluminum, or other tough alloys, saw blades used for metal cutting must endure extreme forces, high temperatures, and abrasive wear. Tungsten carbide tips are widely used in saw blades for metal cutting due to their exceptional hardness, wear resistance, and longevity. In this blog, we will explore how tungsten carbide tips improve the performance of saw blades, increase cutting efficiency, and reduce operational costs in metal cutting applications. 1. What Is Tungsten Carbide and Why Is It Ideal for Metal Cutting? Tungsten carbide is a metal composite made from tungsten and carbon, creating […]

Tungsten Carbide Tips for Industrial Milling and Shaping Hard Metals

When it comes to industrial milling and shaping of hard metals, choosing the right cutting tools is essential for ensuring precision, efficiency, and long tool life. Tungsten carbide tips are widely regarded as the best option for these applications due to their exceptional hardness, wear resistance, and heat resistance. In this blog, we’ll explore how tungsten carbide tips improve milling and shaping operations for hard metals, including their advantages, applications, and cost-effectiveness. 1. Why Tungsten Carbide Tips Are Essential for Milling and Shaping Hard Metals Milling and shaping hard metals such as steel, titanium, and alloys can cause significant wear and tear on tools. Tungsten carbide tips are an ideal […]

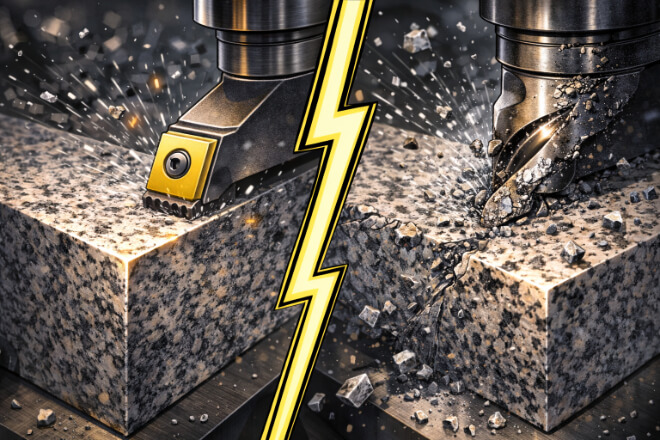

Using Tungsten Carbide Tips for Stone and Granite Cutting: What You Should Know

Cutting stone and granite can be a challenging task. These materials are tough, dense, and often abrasive, which means they can quickly wear out standard cutting tools. This is where tungsten carbide tips come into play. Known for their hardness and wear resistance, tungsten carbide tips help improve cutting performance, reduce tool wear, and enhance overall productivity. In this blog, we will explore how tungsten carbide tips are used for stone and granite cutting, their benefits, and what you need to know before choosing the right tips for your cutting operations. 1. Why Tungsten Carbide Tips Are Ideal for Stone and Granite Cutting Stone and granite are some of the […]

Best Tungsten Carbide Tips for Precision Woodworking and Cabinet Making

In woodworking, precision and efficiency are essential to creating high-quality products. Whether it’s crafting fine furniture or building cabinets, the tools used must be durable, accurate, and capable of cutting through various wood types smoothly. Tungsten carbide tips are widely used in woodworking tools because they offer excellent durability, sharpness, and resistance to wear. In this article, we’ll explore the best tungsten carbide tips for precision woodworking and cabinet making, highlighting their advantages and how they improve cutting performance. 1. Why Tungsten Carbide Tips Are Ideal for Woodworking Tungsten carbide is a highly durable and hard material made from tungsten and carbon, making it perfect for cutting through tough materials […]

Tungsten Carbide Tips in Power Tool Applications: From Masonry Drills to Core Drills

Power tools are an essential part of various industries, from construction to manufacturing. Drilling tools, in particular, face high demands, especially when working with tough materials like concrete, stone, or metal. Tungsten carbide tips are commonly used in power tools for their exceptional durability, hardness, and resistance to wear. Whether it’s masonry drills or core drills, tungsten carbide tips significantly improve performance, longevity, and efficiency. In this blog, we’ll explore how tungsten carbide tips enhance power tool performance and their applications across different drilling tasks. 1. What Makes Tungsten Carbide Ideal for Power Tools? Tungsten carbide is a metal composite made of tungsten and carbon. It is well-known for its […]

Tungsten Carbide Tips for Asphalt Milling Teeth: Tips for Selection and Wear Balance

Asphalt milling is one of the most demanding operations in road construction and maintenance. Milling teeth work under constant impact, abrasion, and heat while cutting through asphalt mixed with aggregates and sometimes concrete. Tungsten carbide tips play a critical role in the performance and life of asphalt milling teeth. Choosing the right carbide tip and maintaining proper wear balance can greatly improve milling efficiency and reduce operating costs. This article explains how tungsten carbide tips are used in asphalt milling teeth, how to select them correctly, and how to manage wear balance for better results. 1. Understanding Asphalt Milling Teeth and Working Conditions Asphalt milling teeth are mounted on rotating […]

Understanding the Tribology of Tungsten Carbide Tips in Cutting Tool Design

In cutting tool design, performance is not only about hardness or strength. How surfaces interact during cutting is just as important. This is where tribology plays a key role. Tribology is the study of friction, wear, and surface contact. For tungsten carbide tips, tribology directly affects tool life, cutting stability, heat generation, and surface quality. This article explains the tribology of tungsten carbide tips in simple terms and shows why it matters for decision-makers involved in cutting tool selection and design. 1. What Is Tribology in Cutting Tool Design? Tribology focuses on how two surfaces behave when they slide or press against each other. In cutting operations, this interaction happens […]

How Tungsten Carbide Tips Improve Cutting Performance in Hard Material Machining — Uses in Metal, Wood, and Plastic Cutting

Machining hard or difficult materials is a common challenge in modern manufacturing. Whether cutting metal, wood, or plastic, tools must handle high stress, friction, and heat while keeping accuracy and speed. Tungsten carbide tips are widely used because they offer strong cutting performance across many materials. This article explains how tungsten carbide tips improve cutting performance in hard material machining and why they are effective for metal, wood, and plastic cutting applications. 1. Challenges of Hard Material Machining Hard material machining puts heavy demands on cutting tools. Materials like hardened metals, dense wood, and reinforced plastics can quickly wear out standard tools. Common challenges include: Fast tool wear High cutting […]