Tungsten carbide has become one of the most important materials in industrial manufacturing.

Its 硬度 and ability to withstand extreme wear make it the go-to choice for 切削工具, mining components, and 耐摩耗部品.

But what often goes unnoticed is the role of binder systems. Without the right binder, carbide parts would be too brittle or inconsistent for real-world use.

This article explores advanced binder systems in modern carbide parts—why they matter, how they work, and what decision-makers in heavy industries need to know.

What Are Binder Systems in Carbide?

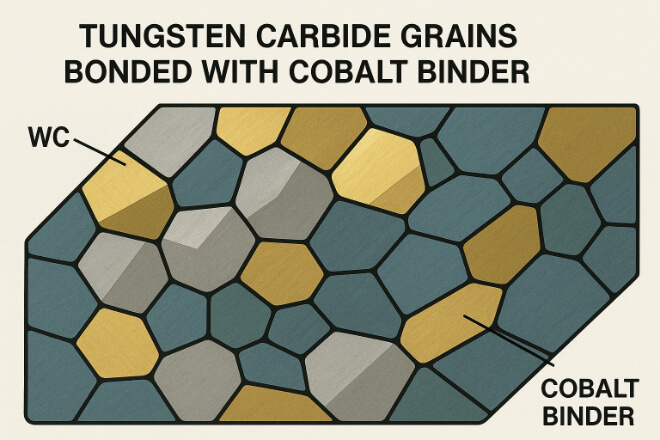

Carbide parts are not made of tungsten carbide alone. They are a composite material, combining hard carbide grains (usually tungsten carbide) with a metal binder (commonly cobalt or nickel).

The binder holds the grains together, adds 強靭さ, and allows the material to resist breaking under heavy loads.

Think of the binder as the “glue” that keeps the hard particles locked in place. Without it, carbide would be almost as hard as diamond but would shatter under impact.

The Role of Cobalt, Nickel, and Alternatives

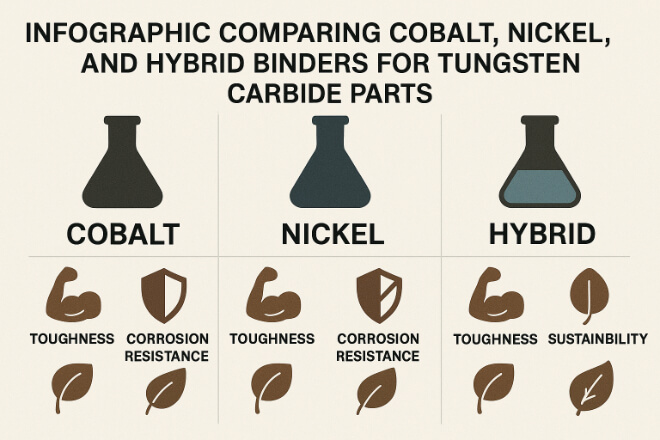

Traditionally, cobalt has been the most common binder metal. It provides excellent toughness and good wetting of tungsten carbide grains. Nickel is also used, especially for corrosive environments.

However, reliance on cobalt has created supply and ethical concerns, since much of the world’s cobalt comes from conflict-prone regions.

This has pushed research into alternative binders such as:

Iron-based binders for lower cost.

Binderless carbides using advanced sintering methods.

Hybrid binders that mix cobalt with other metals for performance balance.

Microstructure and Performance

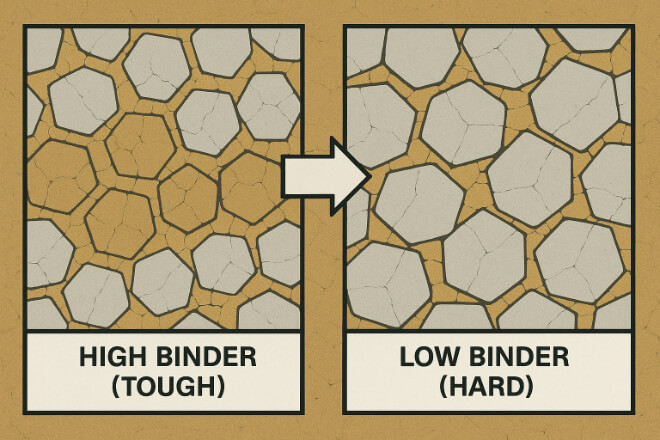

The amount and distribution of binder directly affect the hardness, toughness, and wear resistance of carbide parts.

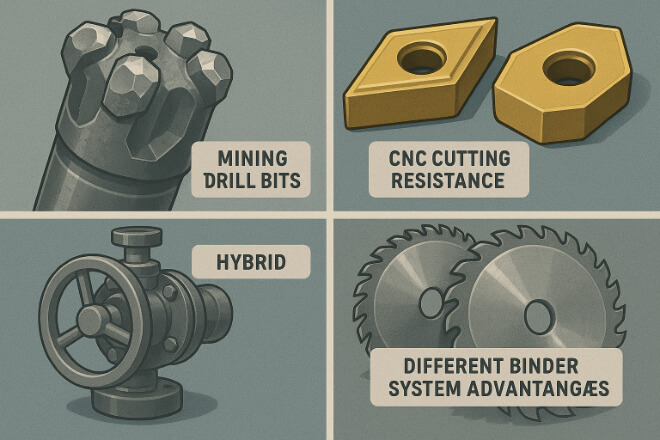

Modern binder systems aim to balance hardness and toughness for specific applications like cutting, drilling, or forming.

For example, a mining drill bit needs higher toughness, while a precision cutting insert may need higher hardness.

Advanced Binder Technologies

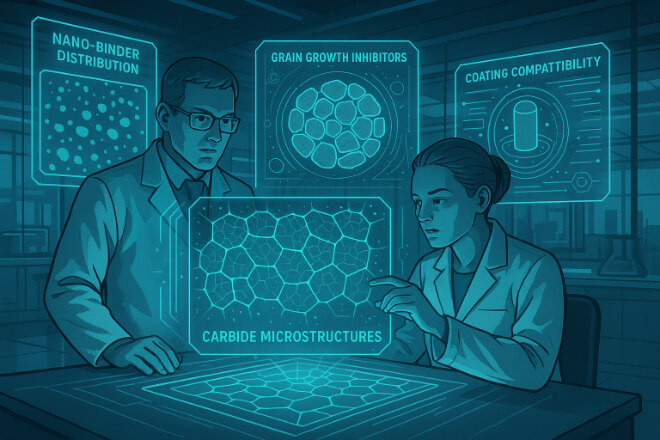

Recent developments in binder systems have improved performance dramatically:

Nano-binder distribution: Ensures even bonding across grains.

Grain growth inhibitors: Prevents carbide grains from getting too large during sintering.

Coating-friendly binders: Designed to improve adhesion for PVD or CVD coatings.

Corrosion-resistant binders: Nickel and hybrid systems for 石油・ガス or chemical industries.

These advances allow carbide parts to last longer, perform better under stress, and reduce total operational costs.

Applications in Different Industries

Binder systems influence how carbide performs across industries:

鉱業: Tough binders resist cracking under impact.

Metal cutting: Balanced binders support high-speed machining.

石油・ガス: Corrosion-resistant binders ensure longer life.

木工 & paper: Optimized binders prevent chipping and wear.

For decision-makers, understanding binder choice helps when selecting suppliers or specifying tooling requirements.

Challenges with Binder Systems

Even with advanced designs, binder systems face challenges:

Cobalt price volatility affects cost planning.

Environmental regulations limit the use of certain binders.

Brittleness vs. toughness trade-off still exists in extreme applications.

Manufacturing precision is required to control binder distribution.

Companies that work closely with suppliers can ensure they get carbide parts designed for their exact environment, avoiding downtime or premature failure.

Future of Binder Systems

The future is moving toward eco-friendly, high-performance binder systems. We are seeing:

Cobalt-free solutions becoming more common.

Additive manufacturing using advanced binders for custom parts.

AI-driven design of binder compositions for different industries.

Recycling systems that recover both tungsten and binder metals.

Decision-makers should monitor these innovations because they will directly affect cost, performance, and sustainability.

結論

Advanced binder systems are the hidden drivers of carbide performance.

For industries that rely on tungsten carbide parts, choosing the right binder system is just as important as choosing the carbide itself.

By working with suppliers that use modern binder technology, businesses can reduce downtime, improve efficiency, and ensure long-term value.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。