スラリーや研磨性流体は、工業用ポンプ、ミキサー、タービンにとって最も扱いが難しい材料の 1 つです。

これらの液体には砂、シルト、鉱物などの固体粒子が含まれており、機器にすぐに損傷を与える可能性があります。

漏れを防ぎ、メンテナンスを減らし、スムーズな運用を維持するためには、信頼性の高いシーリング システムが不可欠です。

入手可能な材料の中には、 タングステンカーバイドシールリング スラリーや研磨性流体の取り扱いに最適な選択肢の 1 つです。

この記事では、その理由を説明し、代替案と比較し、意思決定者向けのヒントを紹介します。

スラリーおよび研磨性流体の取り扱いにおける課題

研磨性流体はシールや機器に特有の問題を引き起こします。

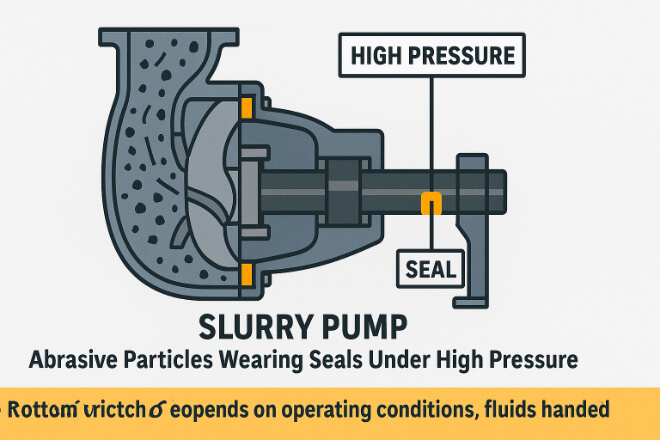

激しい摩耗 → 固体粒子がシール部分に擦れて、急速な損傷を引き起こします。

高圧 → スラリーポンプは極端な負荷がかかった状態で稼働することがよくあります。

可変フロー → 不均一な条件によりシール部分にストレスがかかる場合があります。

腐食 → 多くのスラリーには化学物質や海水が含まれています。

ダウンタイムコスト → シールが破損すると生産が停止し、高額な修理費用が発生する可能性があります。

これらの課題に対処するには、激しい摩耗やストレスに耐えられる素材が必要です。

他のシール材に対する利点

| 特徴 | タングステンカーバイド | セラミック | 鋼鉄 |

|---|---|---|---|

| 耐摩耗性 | 研磨剤に最適 | スラリー中程度 | 研磨液が不足している |

| 強靭さ | 高い; 衝撃/振動に強い | 低い; 衝撃を受けると脆くなる | 適度 |

| 耐腐食性 | 良好;ニッケル結合が優れている | 化学薬品に優れている | スラリー/化学薬品が不足している |

| 耐用年数 | ストレス下でも長持ち | 適度 | 厳しいメディアに弱い |

| 料金 | 初期投資額は高いが、ROIは高い | 初期コストが低い | 初期コストが最も低い |

スラリーおよび研磨流体システムにおけるアプリケーション

タングステンカーバイドシールリングは、次のような用途で広く使用されています。

採鉱および浚渫ポンプ – 研磨性の高い鉱物スラリーを扱います。

油田掘削システム – 圧力下で研磨性の掘削流体を管理します。

廃水処理 - 砂利を含んだ液体による摩耗に耐えます。

海洋および浚渫作業 - 砂質海水中での耐久性を提供します。

化学工場 – 腐食性および研磨性の混合物を安全に取り扱います。

コスト vs 長期的な価値

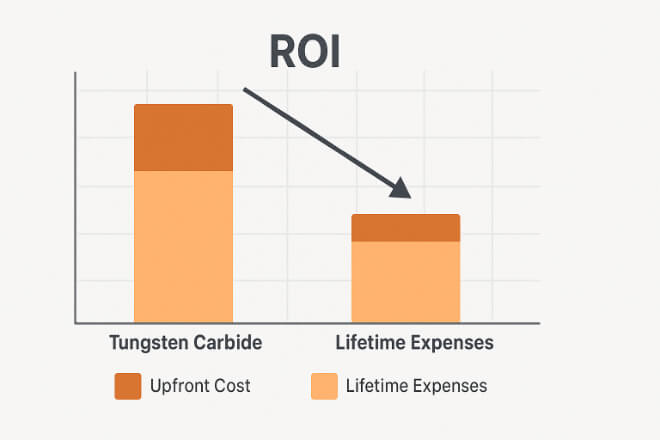

タングステンカーバイドシールリングは初期費用が高くなりますが、次のような利点があります。

ダウンタイムを削減 → 故障や交換の頻度が少なくなります。

メンテナンスコストの低減 → 労働時間とスペアパーツの削減。

機器を保護する → ポンプやシャフトへの高額な損害を防止します。

ROIの向上 → 耐用年数が長いため、初期価格を相殺できます。

スラリー処理の意思決定者は、長期にわたるライフサイクル コストの低減から利益を得ます。

タングステンカーバイドシールリングの使用に関するベストプラクティス

研磨環境でパフォーマンスを最大限に高めるには:

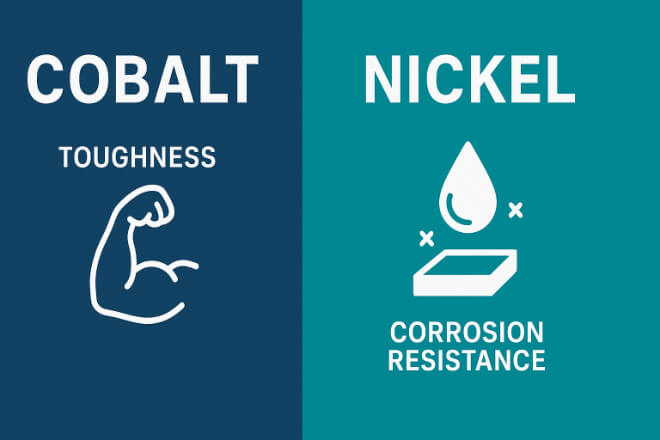

適切なバインダーを選択する → 腐食性スラリーにはニッケル、衝撃荷重にはコバルトを使用します。

慎重に取り付けてください → 寿命を縮める傷やずれを避けてください。

適切な潤滑剤を使用する → 熱と摩擦による摩耗を軽減します。

定期的に検査する → 故障を防ぐために、摩耗を早期に発見します。

経験豊富なサプライヤーと協力 → システムに適した材質と設計であることを確認してください。

環境上の利点

タングステンカーバイドはリサイクル可能です。摩耗したリングは回収され、新しい製品に再加工できるため、廃棄物を削減し、環境の持続可能性に貢献します。これは世界中の産業界にとってますます重要な課題となっています。

意思決定者にとっての重要なポイント

タングステンカーバイドシールリングは、研磨性、高圧環境において鋼やセラミックよりも優れた性能を発揮します。

適切なバインダー(ニッケルまたはコバルト)により、特定の条件下での信頼性が確保されます。

初期費用は高くなりますが、タングステンカーバイドを使用するとダウンタイムと全体的な経費が削減されます。

リサイクル可能であることで持続可能性のメリットが加わります。

結論

スラリーや研磨性流体を扱うには、極度の摩耗、圧力、腐食に耐えられるシールが必要です。

タングステンカーバイドシールリングは、ポンプ、コンプレッサー、タービンを安全かつ効率的に動作させるために必要な強度と耐久性を備えています。

意思決定者にとって、タングステンカーバイドを選択することは、稼働時間、パフォーマンス、持続可能性への戦略的な投資です。

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。