Renewable energy systems—such as wind turbines, hydroelectric plants, solar farms with pumps, and geothermal systems—operate under tough environmental conditions.

Their components must run for years with minimal maintenance to keep energy production efficient and cost-effective.

One critical component is the seal ring. In pumps, turbines, and compressors, seals prevent fluid leaks, protect bearings, and ensure energy efficiency.

Among available materials, tungsten carbide seal rings offer superior performance for renewable energy equipment.

Why Seal Rings Matter in Renewable Energy Systems

Seal failures can:

Cause fluid leaks in hydraulic or coolant systems.

Increase downtime, reducing energy output.

Lead to extra maintenance costs and safety risks.

Lower equipment efficiency, wasting renewable energy.

Reliable seals ensure continuous operation and better return on investment for wind, hydro, solar, and geothermal projects.

炭化タングステンシールリングの主な特性

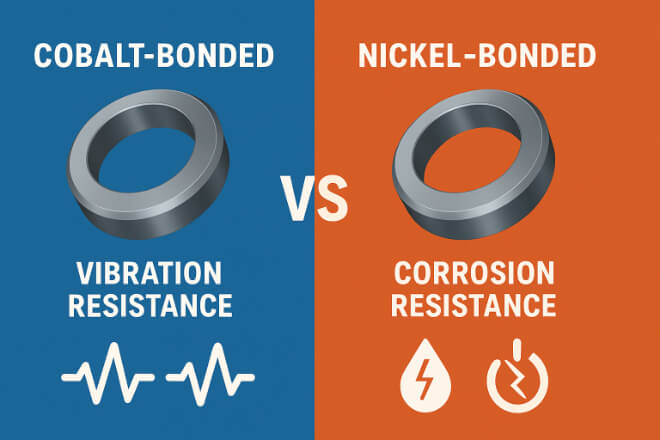

Tungsten carbide is a composite of tungsten and carbon, bonded with cobalt or nickel. Its key properties include:

他のシール材に対する利点

| 特徴 | タングステンカーバイド | セラミック | 鋼鉄 |

|---|---|---|---|

| 耐摩耗性 | 素晴らしい | 適度 | 貧しい |

| 耐腐食性 | High (nickel grades) | Very Good | 低い |

| 強靭さ | 高くて衝撃に強い | 低く、脆い | 適度 |

| Thermal Performance | Excellent at high heat | 良い | 適度 |

| Service Life | 長持ちする | 適度 | 短い |

Applications in Renewable Energy Equipment

タングステンカーバイドシールリングは次のような用途に使用されます。

Wind turbines → Gearboxes and hydraulic systems.

Hydroelectric plants → Pumps and turbines handling water with debris.

Solar farms → Cooling and circulation pumps.

Geothermal plants → High-temperature pumps and compressors.

Marine energy systems → Tidal and wave energy converters exposed to seawater.

コスト vs 長期的な価値

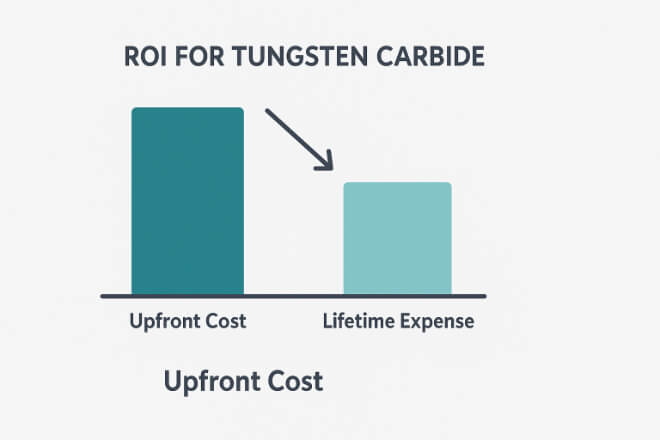

While tungsten carbide seal rings cost more upfront:

They last longer, reducing downtime and maintenance.

They prevent leaks that can damage expensive renewable equipment.

Their durability leads to better ROI over the project’s lifetime.

環境上の利点

Recyclable material → Worn rings can be recovered and reused.

Less waste → Fewer replacements mean reduced landfill disposal.

Higher efficiency → Preventing leaks saves energy and reduces emissions.

For renewable energy companies committed to sustainability, tungsten carbide aligns with green operational goals.

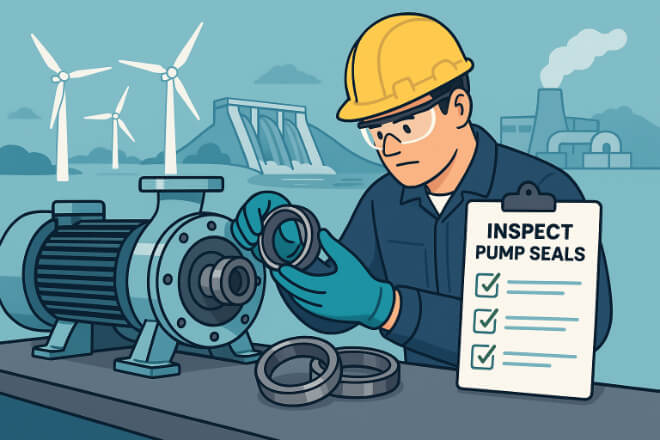

Best Practices for Choosing and Using Tungsten Carbide Seal Rings

Evaluate the operating environment → Corrosive water? High vibration? Choose the right binder.

経験豊富なサプライヤーと協力 → Ensure correct specifications for renewable systems.

Install correctly → Avoid scratches or misalignment that cause leaks.

定期的に検査する → Prevent failures before they cause costly downtime.

Recycle worn rings → Support circular manufacturing and sustainability.

意思決定者にとっての重要なポイント

Tungsten carbide seal rings ensure durability, efficiency, and sustainability in renewable energy equipment.

Choose nickel-bonded for corrosion-heavy environments and cobalt-bonded for vibration-heavy systems.

The higher upfront cost is justified by long-term savings and environmental benefits.

Reliable seals improve energy production and equipment protection across wind, hydro, solar, geothermal, and marine systems.

結論

Renewable energy equipment must operate reliably for decades under demanding conditions. Tungsten carbide seal rings provide the hardness, strength, and corrosion resistance needed for these critical systems.

For decision-makers, investing in tungsten carbide seal rings supports efficiency, cost savings, and environmental responsibility, making them the smart choice for renewable energy operations.

企業の詳細を知りたい場合は、お気軽にお問い合わせください。 お問い合わせ。